9307906

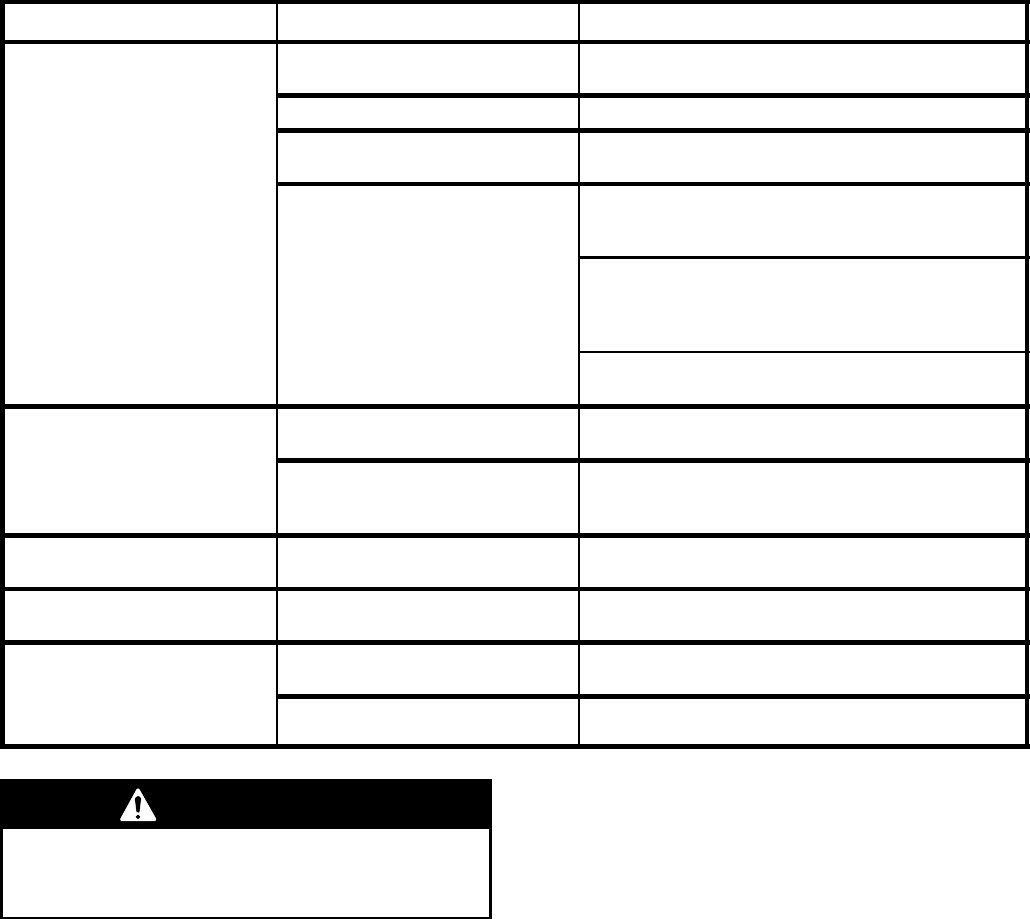

Troubleshooting

Problem Cause Solution

Pump does not run. There is no fluid demand. In a closed-end system the pump runs only when

there is demand for fluid.

Air supply is insufficient. Check air supply. Increase air pressure or volume.

Fluid outlet line or intake valve is

clogged.

Relieve the pressure. Check and clear obstructions.

Air motor parts are worn or

damaged.

Check the piston o-rings (15a*, 15b*) and exhaust

plate (15c*) for swelling. Replace if necessary. See

page 10.

Check the piston assembly (15). Be sure its screws

are properly torqued (10 to 14 in-lb [1.3 to 1.6 N-m])

and that the assembly is hand-tightened onto the

piston rod.

Check the springs (8, 17) for wear or damage, and

replace as needed.

Pump speeds up or runs

erratically.

Material viscosity is too high. Reduce viscosity. Reduce pump speed when running

viscous materials.

Pump throat packings, piston or

piston packings, or intake valve is

worn.

Relieve the pressure. Check and repair. See pages

10 and 11.

Pump slows down or runs

erratically.

Air motor is icing. Shut off pump and allow to warm up. Run pump at a

lower air pressure.

Pump runs, but output is low on

up or down stroke.

Pump piston and/or intake valve is

worn.

Relieve the pressure. Check and repair. See pages

10 and 11.

Pump runs, but output is low on

both strokes.

Air supply is insufficient. Check air supply. Increase air pressure or volume.

Fluid outlet line, intake valve, or

dispense valve is clogged.

Relieve the pressure. Check and clear obstructions.

WARNING

To reduce the r isk of s e rious injury whenever y ou

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 8.