6 307906

Installation

Grounding

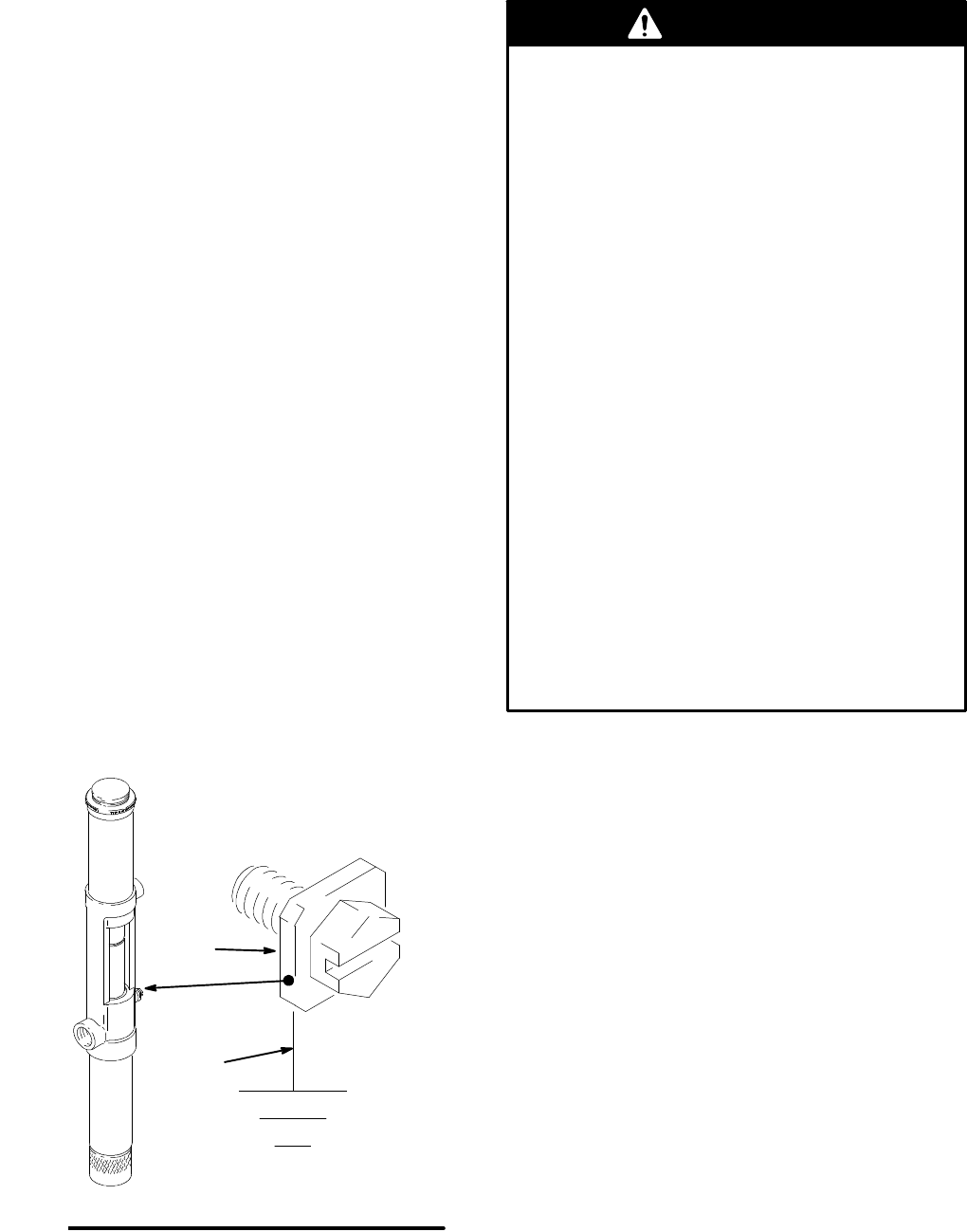

Proper grounding is an essential part o f maintaining a

safe system.

To reduce the r isk of s tatic sparking, ground the pump.

Check your local e lectrical code for detailed grounding

instructions for your area and type of equipment. Be

sure to ground all of this equipment:

D Pump: Us e a ground wire and clamp as s hown in

Fig. 2.

D Air c ompressor: Follow the manufacturer’s recom-

mendations.

D Object being dis pensed to: Follow the local c ode.

D Fluid s upply c ontainer: Follow the local c ode.

D To maintain grounding continuity when flushing or

relieving pressure, alway s hold a metal part of the

dispensing valve firmly to the side of a grounded

meta l container , then trigger the valve.

To ground the pump, remove the ground screw (Z)

and insert through the eye of the r ing terminal at end of

ground wire (Y). Faste n t he ground s crew back onto

the pump and tighten securely. Connect the other end

of the wire to a true earth ground. To order a ground

wire and clamp, order Part No. 222011.

Y

Z

05941B

Fig. 2

System Accessories

Three a ccessories are required in your system:

bleed-type master air valve, fluid drain v alve, and

grounding wire. Additionally, for per manent installa-

tions, a thermal relief kit is required. These acces-

sories help reduce the r isk of serious bodily injury,

including fluid injection, splashing in the eyes or on

the skin, injury from moving parts if you are adjus t-

ing o r r epairing the pump, and explosion from

static sparking.

D The bleed-type master air valve ( E) relieves air

trapped between it and the air motor after the

air supply is s hut off. Trapped air can c ause the

air motor to cycle unexpectedly, causing serious

injury if you are adjusting or r epairing the pump.

As an alternative, use a quic k-disconnect

coupler and fitting. In stall them near the pum p

air inlet within easy reach from the pump.

D The fluid drain v alve ( N) assists in r elieving fluid

pressu re in the displacement pump, hoses, and

dispensing valve. T riggering the valve to relieve

pressu re m ay not be sufficient.

D The ground wire (G) reduces the risk of static

sparking.

D The thermal relief kit (R) assists in r elieving

pressu re in the pump, hose, and dispensing

valve due to heat expansion.

WARNING

D Extension Tubes : Pump m odels 222103 and

222104 have extensions tubes. An extension tube

may be added to the Universal pump for use in

submerged applications. To i nstall, apply PTFE

tape to the female threads at the top of the tube.

Thread the tube tightly into the i ntake housing of

the Universal pump. Also, install a bung adapter. To

order a standard 2-in. bung adapter, order Part No.

222308.

D Air and Fluid Hose Kits (F): An 18-in. kit for wall-

mounted pumps and a 6-ft. kit for drum-mounted

pumps are available. Use a minimum 1/4-in. ID air

supply hose between the pump air inlet and the air

accessories. To order a kit with 1/4- in. air hose,

1/4- in. swivel elbow, 3/4-in. fluid hose, and 3/4-in.

swivel elbow, order one of the kits below:

222118 18-in. (0.4 m) hos e kit for w all-mounted

pumps

222119 6-ft (1.8 m) hose kit for d rum-mounted

pumps