4

PRODUCT DESIGN

GPH Package Units are designed for outdoor installations

only in either residential or light commercial applications.

The connecting ductwork (Supply and Return) can only be

connected for horizontal airflow.

A return air filter must be installed behind the return air grille(s)

or provision must be made for a filter in an accessible loca-

tion within the return air duct. The minimum filter area should

not be less than those sizes listed in the Specification Sec-

tion. Under no circumstances should the unit be operated

without return air filters.

A 3/4" pipe is provided for removal of condensate water from

the indoor coil. In order to provide proper condensate flow, a

drain trap is supplied and shipped loose inside the unit for

field installation. (Do not reduce the drain line size).

Refrigerant flow control is achieved by use of restrictor ori-

fices.

Package Heat Pump models use a combination of restrictor

orifices and thermostatic expansion valves for refrigerant flow

control.

Some heat pump models also have a suction line accumula-

tor installed between the reversing valve and the compressor.

The object of the accumulator is to:

1. Provide a liquid refrigerant storage vessel during prolonged

system off cycles.

2. Store excess liquid refrigerant not needed by the system

while running.

3. Return oil and saturated vapor to the compressor at a

controlled rate.

4. Retain stored excess refrigerant during a sudden system

pressure fluctuation such as seen in defrost cycles.

Refrigerant flow control is achieved by use of restrictor ori-

fices. GPH units use the FasTest Access Fitting System,

with a saddle that is either soldered to the suction and liquid

lines or is fastened with a locking nut to the access fitting

box (core) and then screwed into the saddle.

NOTE: The

core must not be removed from the saddle until the

refrigerant charge has been removed. Failure to do so

could result in property damage or personal injury.

The single phase units use permanent split capacitor (PSC)

design compressors. Starting components are not required

for these units. A low microfarad run capacitor assists the

compressor to start and remains in the circuit during opera-

tion.

The outdoor fan and indoor blower motors are single phase

capacitor type motors. GPH1360H41* units have EEM in-

door blower motors that are energized by a 24V signal from

the IBR and are constant torque motors with very low power

consumption. The EEM features an integral control module.

Air for condensing (cooling cycle) or evaporation (heating

cycle) is drawn through the outdoor coil by a propeller fan,

and is discharged vertically out the top of the unit. The out-

door coil is designed for .0 static. No additional restriction

(ductwork) shall be applied.

Conditioned air is drawn through the filter(s), field installed,

across the coil and back into the conditioned space by the

indoor blower.

Package Heat Pump indoor sections are designed to accept

optional components such as auxiliary electric heaters and

circuit breakers. Provisions for these components have been

made at time of manufacture.

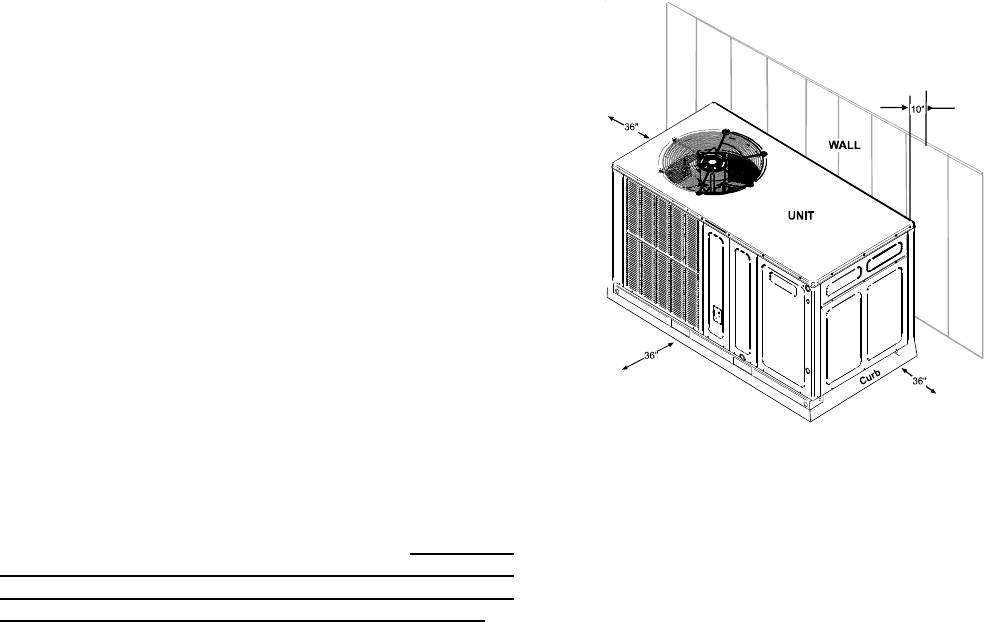

Location and Clearances

NOTE: To ensure proper condensate drainage, unit must be

installed in a level position.

Outside Slab Installation - Horizontal (H)

NOTE: Roof overhang should be no more than 36" and provi-

sions made to deflect the warm discharge air out from the

overhang.

Minimum clearances are required to avoid air recirculation

and keep the unit operating at peak efficiency.