12

SPEED TAP ADJUSTMENTS FOR INDOOR BLOWER MOTOR

PSC Motor

Adjust the CFM by changing the speed tap of the indoor blower

motor at the EBTDR “COM” connection with one of the speed taps

on “M1” or “M2”. (Black-High Speed, Blue-Medium Speed, Red-

Low Speed.)

X-13 Motor

Adjust the CFM by changing the 24V low voltage lead at the speed

terminal block on the motor. (T1-Low Speed, T2 and T3-Medium

Speed, T4 and T5-High Speed).

REFRIGERANT CHARGE C HECKS

After completing airflow measurements and adjustments, the unit’s

refrigerant charge must be checked. The unit is factory charged

based on 400 CFM per ton at minimum ESP per AHRI test condi-

tions (generally between .15 - .25 ESP). When air quantity or ESP

is differs from this, charge must be readjusted to the proper amount.

All package units are charged to the superheat method at the

compressor suction line (these are fixed orifice devices).

For charging in the warmer months, 8 +/-3

º

F superheat at the com-

pressor is required at conditions: 95

º

F outdoor ambient (dry bulb

temperature), 80

º

F dry bulb / 67

º

F wet bulb indoor ambient, ap-

proximately 50% humidity. This superheat varies when conditions

vary from the conditions described.

A superheat charge chart is available for other operating condi-

tions. Use it to provide the correct superheat at the conditions the

unit is being charged at.

After superheat is adjusted it is recommended to check unit sub-

cooling at the condenser coil liquid line out. In most operating

conditions 10 - 15ºF of sub-cooling is adequate.

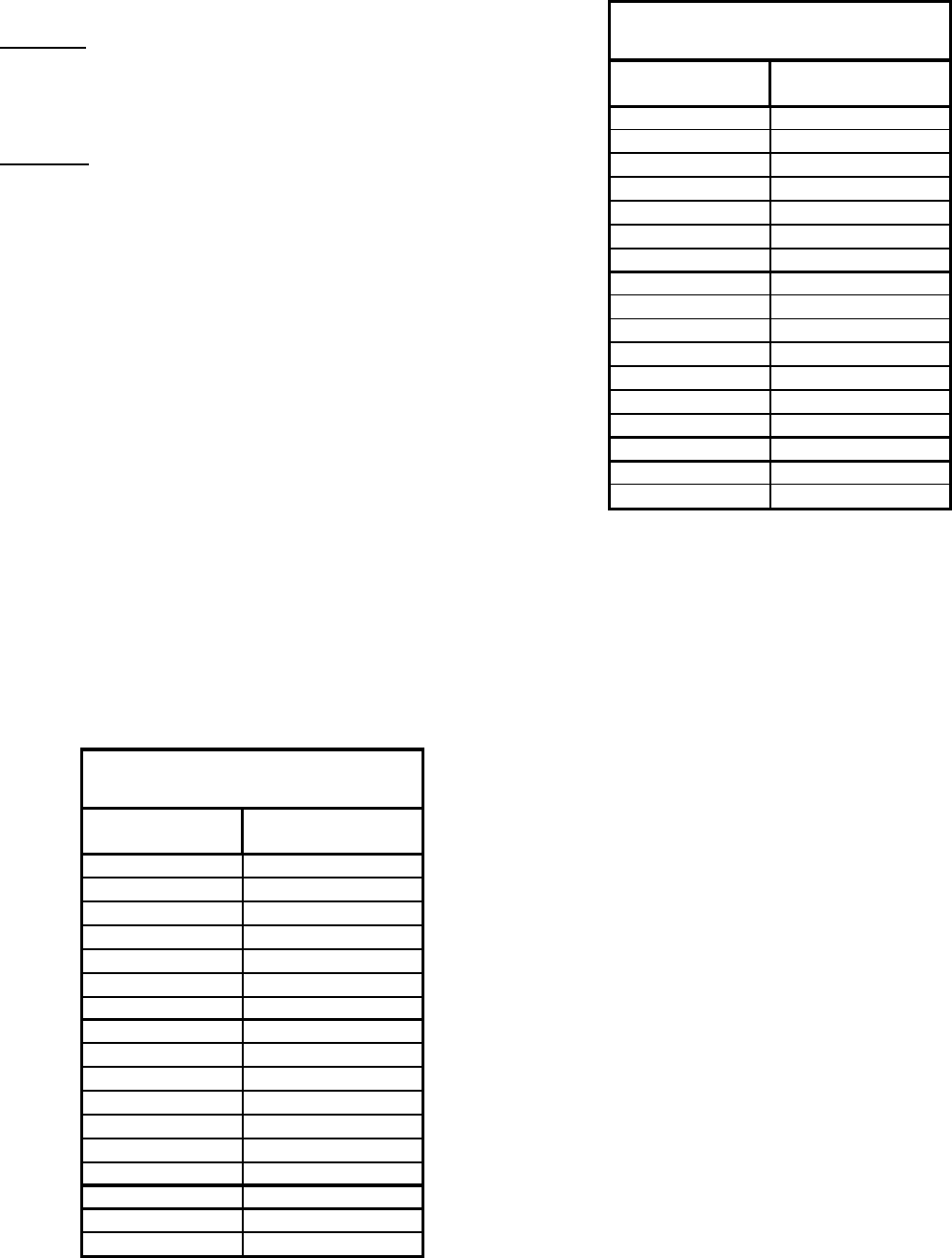

SUPERHEAT = SUCTION LINE TEMP - SAT. SUCTION TEMP

Suction

Pressure

Saturated Suction

Tem

p

erature °F

PSIG R-410A

50 1

52 3

54 4

56 6

58 7

60 8

62 10

64 11

66 13

68 14

70 15

72 16

71 17

76 19

78 20

80 21

SATURATED SUCTION PRESSURE

TEMPERATURE CHART

SUBCOOLING = SAT. LIQUID TEMP. - LIQUID LINE TEMP.

Liquid

Pressure

Saturated Liquid

Tem

p

erature °F

PSIG R-410A

200 70

210 73

220 76

225 78

235 80

245 83

255 85

265 88

275 90

285 92

295 95

305 97

325 101

355 108

375 112

405 118

SATURATED LIQUID PRESSURE

TEMPERATURE CHART

SYSTEM SUPERHEAT

SUPERHEAT CAN BE DETERMINED AS FOLLOWS:

1. Read suction pressure. Determine Saturated Suction

Temperature from tables or pressure gauge saturated

temperature scale (R-410A).

2. Read suction line temperature.

3. Use the following formula:

SUPERHEAT = SUCTION LINE TEMP - SAT. SUCTION TEMP

ELECTRICAL ADJUSTMENTS

This series of electric cooling and, heat pump package equipment

is designed to accept a field installed electric heat kit. The unit is

equipped to easily install the HKR Series Electric Heat Kit. Full In-

stallation Instructions are included in this kit. Please use this docu-

ment for guidance in field equipping the package unit with electric

heat.

Choose the heat kit that fits the application for the specific installa-

tion. Permanently mark the unit’s nameplate with the model being

installed. High and low voltage connections are detailed in the heat

kit instructions.

Indoor Blower motor speed tap selection may need to be modified

to accommodate normal continuous operation to prevent a nui-

sance trip. See following table.