PLUMB “IN” AND “OUT” PIPES

TO AND FROM SOFTENER

CAUTION: Observe all of the following

cautions as you connect inlet and outlet

plumbing. See Typical Installation Illustration.

• BE SURE INCOMING HARD WATER SUPPLY IS

DIRECTED TO THE SOFTENER VALVE INLET PORT.

If house water flow is from the right, use a

plumbing crossover as shown in Typical

Installation Illustration.

• With the softener in place, determine the

correct length of piping required to connect the

household plumbing to the 1″ copper adapter

on the softener. Test fit all connections.

NOTE: The softener must not support the home’s

plumbing in the vertical direction. Secure the

inlet and outlet pipes to the wall/ceiling using pipe

clamps or straps. Be certain the home’s plumbing

does not exert any force on the softener bypass.

• Remove softener from installation space.

• Disconnect copper adapters and union nuts from

bypass valve.

• Reconnect copper adapters with union nuts

and gaskets in place to home plumbing. Before

soldering adapters, slide union nuts and gasket

away from area being soldered. NOTE: Torch heat

will damage plastic parts.

• Support inlet and outlet plumbing in some manner

(use pipe hangers or clamps) to keep the weight

off of the valve fittings.

• Slide softener back into position.

• Make final connections to the bypass valve.

3

Installation Instructions

7

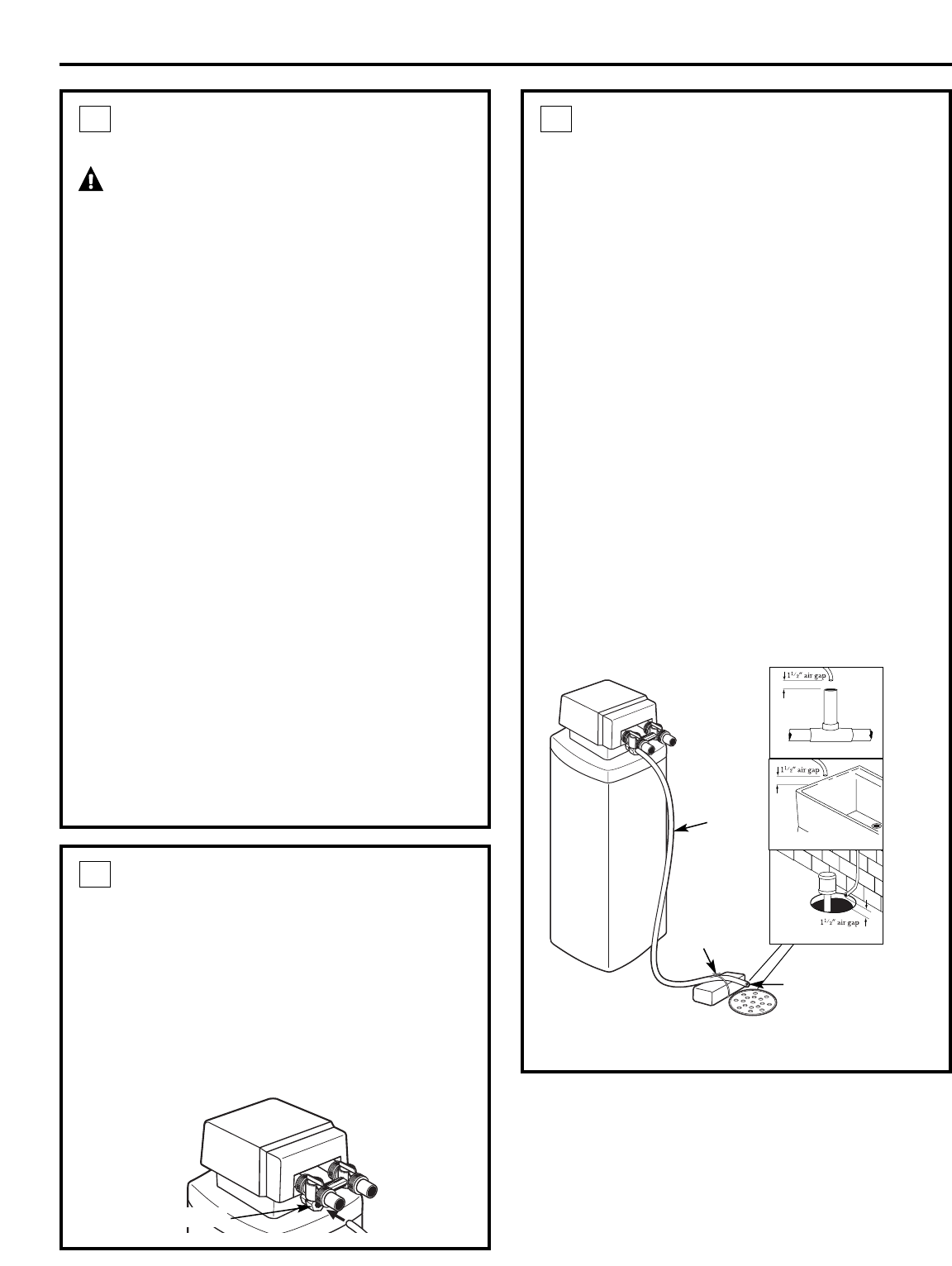

CONNECT AND RUN THE VALVE

DRAIN HOSE

• Check that drain port on valve body has white

tape on it. If not, apply Teflon Tape to threads

prior to installing the valve drain fitting.

• Connect valve drain fitting to valve drain port.

Tighten connection with a wrench.

• Connect 1/2″ diameter drain hose (not provided)

to the valve drain fitting. Tighten connections with

wrench.

4

CONNECT AND RUN THE VALVE

DRAIN HOSE

(CONT.)

• Locate the other end of the hose at a suitable

drain point (floor drain, sump, laundry tub, etc.)

that terminates at the sewer. Check and comply

with local codes.

• Tie or wire the hose in place at the drain

point. High water pressure will cause it to whip

during the back-wash and fast rinse cycles of

regeneration. Also provide an air gap of at least

1-1/2″ between the end of the hose and the

drain point. An air gap prevents possible

siphoning of sewer water into the softener,

if the sewer should “back-up.”

The water softener will not work if water cannot

exit this hose during regeneration.

• Elevating the drain hose may cause back

pressure that could reduce the brine draw during

regeneration. If raising the drain line overhead is

required to get to the drain point, measure the

inlet water pressure to the softener first. For inlet

pressures between 20 and 50 psi, do not raise

higher than 8′ above the floor. For inlet pressure

above 50 psi, the drain line may be raised to a

maximum height of 14′.

4

Valve

drain

hose

FLOOR DRAIN

Tie or

wire hose

in place

1

1

⁄2″ air gap

LAUNDRY TUB

SUMP

STANDPIPE

Valve drain

hose connection