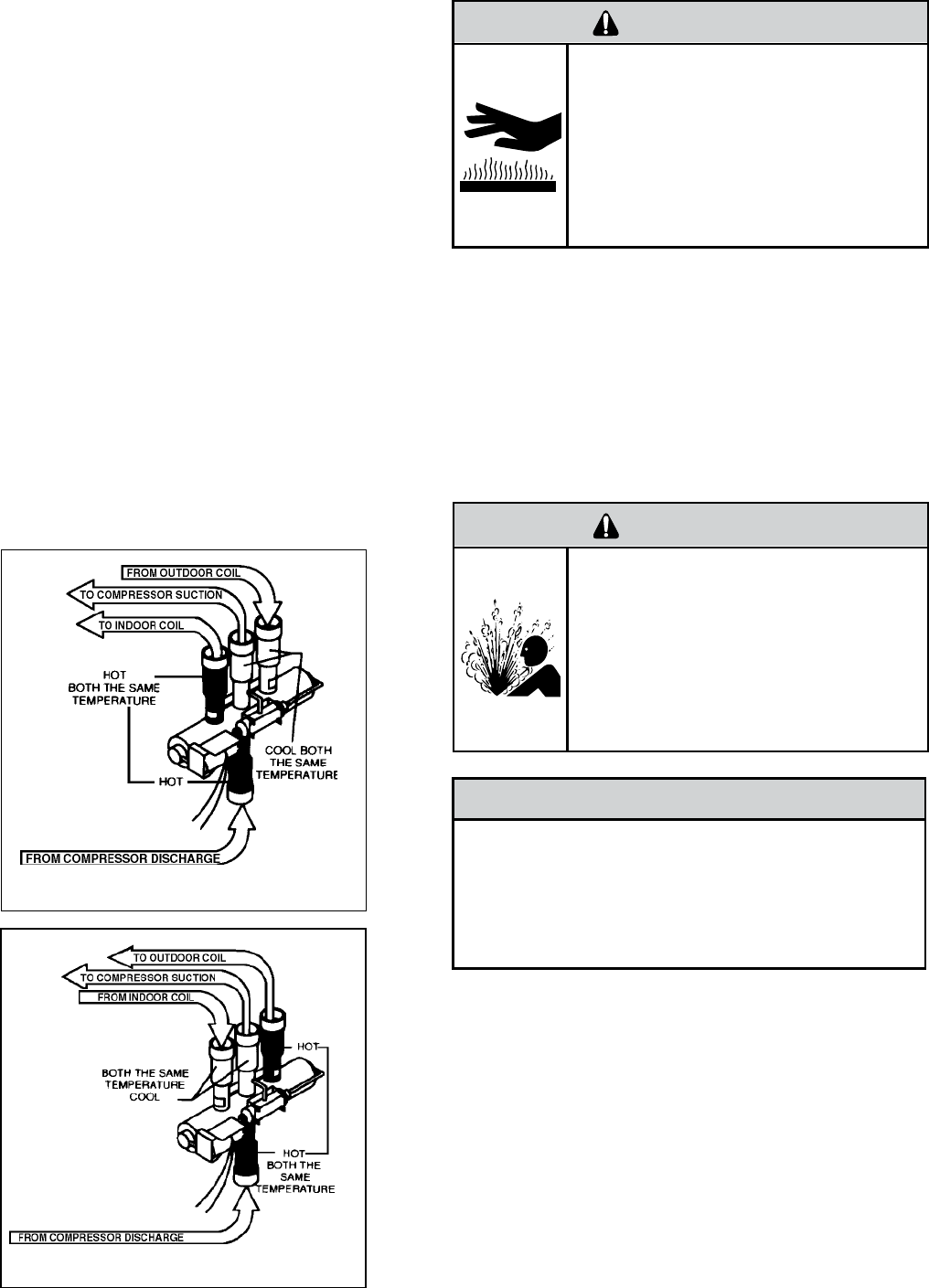

Reversing Valve in Heating Mode

When sluggish or stuck in the mid-position, part of the

discharge gas from the compressor is directed back to the

suction side, resulting in excessively high suction pressure.

Should the valve fail to shift from coooling to heating,

block the air fl ow through the outdoor coil and allow the

discharge pressure to build in the system. Then switch the

system from heating to cooling.

If the valve is stuck in the heating position, block the air

fl ow through the indoor coil and allow discharge pressure

to build in the system. Then switch the system from heating

to cooling.

Should the valve fail to shift in either position after increasing

the discharge pressure, replace the valve.

Dented or damaged valve body or capillary tubes can

prevent the main slide in the valve body from shifting.

If you determing this is the problem, replace the reversing

valve.

After all of the previous inspections and checks have been

made and determined correct, then perform the “Touch

Test” on the reversing valve.

Reversing Valve in Cooling Mode

Procedure For Changing Reversing Valve

1. Install Process Tubes. Recover refrigerant from sealed

system. PROPER HANDLING OF RECOVERED

REFRIGERANT ACCORDING TO EPA REGULATIONS

IS REQUIRED.

2. Remove solenoid coil from reversing valve. If coil is to

be reused, protect from heat while changing valve.

3. Unbraze all lines from reversing valve.

4. Clean all excess braze from all tubing so that they will

slip into fi ttings on new valve.

5. Remove solenoid coil from new valve.

The use of a torch requires extreme care and proper

judgment. Follow all safety recommended precautions

and protect surrounding areas with fi re proof materials.

Have a fi re extinguisher readily available. Failure to follow

this notice could result in moderate to serious property

damage.

NOTICE

FIRE HAZARD

Touch Test in Heating/Cooling Cycle

The only definite indications that the slide is in the mid-

position is if all three tubes on the suction side of the valve

are hot after a few minutes of running time.

NOTE: A condition other than those illustrated above, and

on Page 31, indicate that the reversing valve is not shifting

properly. Both tubes shown as hot or cool must be the same

corresponding temperature.

Certain unit components operate at

temperatures hot enough to cause burns.

Proper safety procedures must be followed,

and proper protective clothing must be

worn.

Failure to follow these procedures could

result in minor to moderate injury.

WARNING

BURN HAZARD

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

HIGH PRESSURE HAZARD

29