9500 Valve

Instruction Manual

Form 2433

November 2007

9

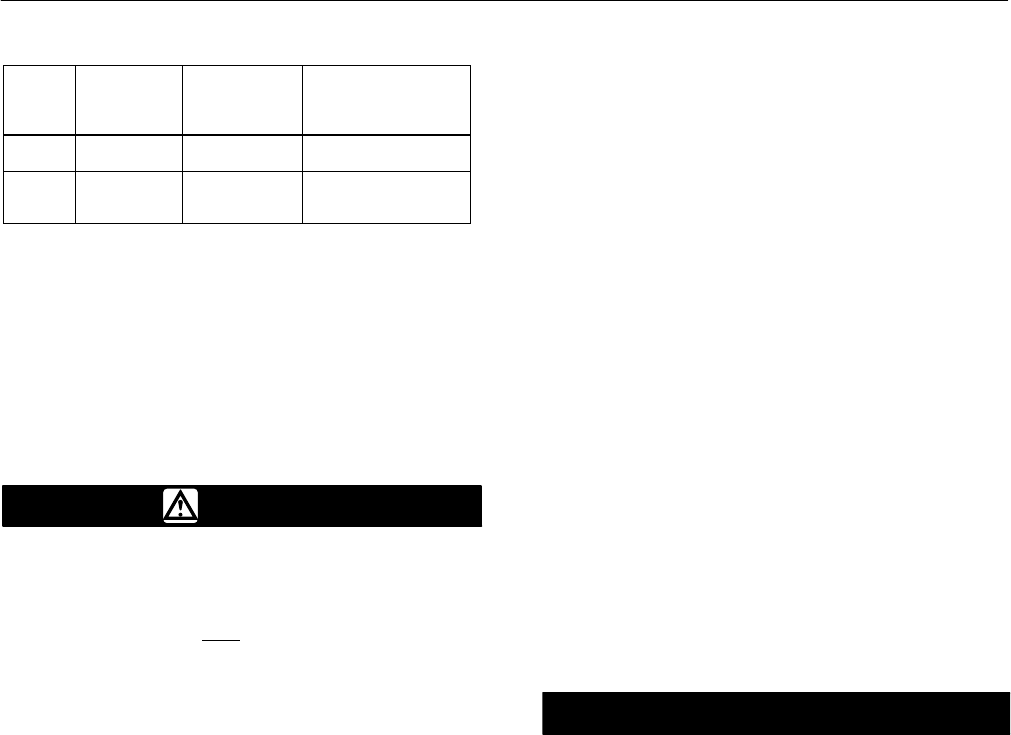

Table 5. Taper Pin Details for 9500 Series Valves

VALVE

SIZE,

NPS

SHAFT

DIAMETER

mm (Inches)

AMERICAN

STANDARD

TAPER

PIN SIZE

DRILL SIZE

2

3, 4

12.7 (1/2)

15.9 (5/8)

2

3

#20 (0.161 Inches)

#16 (0.177 Inches)

6

8, 10

12

19.1 (3/4)

25.4 (1)

31.8 (1-1/4)

4

6

7

13/64 Inches

9/32 Inches

21/64 Inches

Reassembly

Before reassembling the valve, clean and inspect all

parts. Key number locations are shown if figure 7.

Refer to the Parts List section to obtain replacement

parts.

WARNING

Do not lubricate parts when used in

oxygen service, or where the

lubrication is incompatible with the

process media. Any

use of lubricant

can lead to the sudden explosion of

media due to the oil/oxygen mixture,

causing personal injury or property

damage.

1. Insert the liner (key 2) into the valve body. A

small amount of silicone grease applied to the

outside surface of the liner will aid insertion of the

liner. However, do not use grease if the valve is to

be used for oxygen service.

In vacuum service applications, upon customer

request, you may use Eccobondr 285/24LV bonding

agent (Fisherr part no. G1414006992) to bond the

liner to the valve. Though bonding is not required

use the lettered steps below when bonding the liner

to the valve body. If a different agent is to be used,

follow instructions furnished by the bonding agent

manufacturer. In absence of instructions, consult

your Emerson Process Management sales office.

a. Roughen bonding surface of liner with a stiff

wire brush. De-grease bonding surfaces of the

liner and valve body with solvent.

b. Mix the two epoxy components thoroughly and

spread a thin coat [approximately 0.38 mm (0.015

inches) thick] of the mixture over all bonding

surfaces of the valve body and liner.

c. Insert the liner into the valve body. Align the

liner shaft holes with valve body shaft holes.

Remove excess bonding agent from shaft holes

and exposed liner surfaces.

d. Insert the disc (key 3), thrust sleeve

assemblies (key 6), and shaft (key 4) into the

valve body. Be sure the thrust sleeve assemblies

engage the liner recesses to ensure proper liner

positioning. Rotate the disc to the closed position.

e. Lay the valve on one valve face and add

weights to the other face to ensure a tight bond.

Allow to cure for 24 hours. Then, proceed with

the following reassembly steps.

2. Insert the thrust sleeve assemblies into the valve

body. Be sure that the thrust sleeve assemblies

enter the liner recesses to align the shaft holes, by

temporarily inserting the shaft(s) (key 4).

3. A new disc and shaft should be installed if the

taper pin holes have been widened by loosening of

the taper pins (key 15).

Omit the following steps 4 through 8 if a new disc

and shaft assembly is to be installed or if the old disc

and shaft are to be reused. Use new taper pins

whenever the disc has been removed.

CAUTION

If a new disc is required, a complete

disc/shaft assembly must be

purchased to avoid damage to valve

parts. The old valve shaft cannot be

used with a new disc.

If a new shaft (without disc) has been purchased, be

sure to mark the shaft to indicate the disc position as

shown in figure 2.

4. Making certain the taper pin holes are on the

actuator side of the valve body, insert the disc into

the valve body. Position the disc at the fully closed

position.

5. Installing splined shaft:

a. If the old shaft is available, insert it into the

valve body and disc. Line up the taper pin holes

in the disc and shaft; measure and record the

distance between the valve body and the splined

end of the shaft. Remove the old shaft and insert

the new, un-drilled shaft. Position the shaft so

that there is the same distance between the valve

body and the end of the shaft as noted above.