GAS LINE CONNECTION

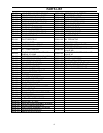

ORIFICE SIZES, PRESSURE AND BTU’S

NATURAL GAS PROPANE GAS

Orifice size #42 dms #53 dms

Manifold pressure. 3.8” wc (0.95 kPa) 11” wc (2.74 kPa)

Min. Manifold pressure. 1.1” wc (0.27 kPa) 2.7” wc (0.67 kPa)

Supply Pressure. 7.0” wc (1.74 kPa) 12” wc (2.98 kPa)

Min. Supply pressure. 5” wc (1.25 kPa) 11.5” wc (2.86 kPa)

Max. BTUH Input. 26,500 Btu/h(7.87 kW) 26,500 Btu/h(7.87 kW)

Min. BTUH Input. 13,500 Btu/h(3.9 kW) 13,500 Btu/h(3.9 kW)

Output fan off 20,700 Btu/h(6.06 kW) 21,200 Btu/h(6.21 kW)

Output fan on 21,200 Btu/h(6.21 kW) 21,700 Btu/h(6.35 kW)

WARNING:

Only persons licensed to work with gas piping may make the necessary gas connections to this appliance.

NOTE: The gas line connection may be made using 3/8" rigid tubing or an approved flex connector. Since some municipalities

have additional local codes it is always best to consult your local authorities and the CAN/CGA-B149 (1 or 2) Installation Code.

For USA gas installations follow either local codes or the current edition of the National Fuel Gas Code ANSI.Z223.1.

UPON CONNECTION, MARK APPROPRIATE FUEL TYPE ON RATING LABEL LOCATED

ON THE INSIDE OF THE RIGHT HAND SIDE PANEL.

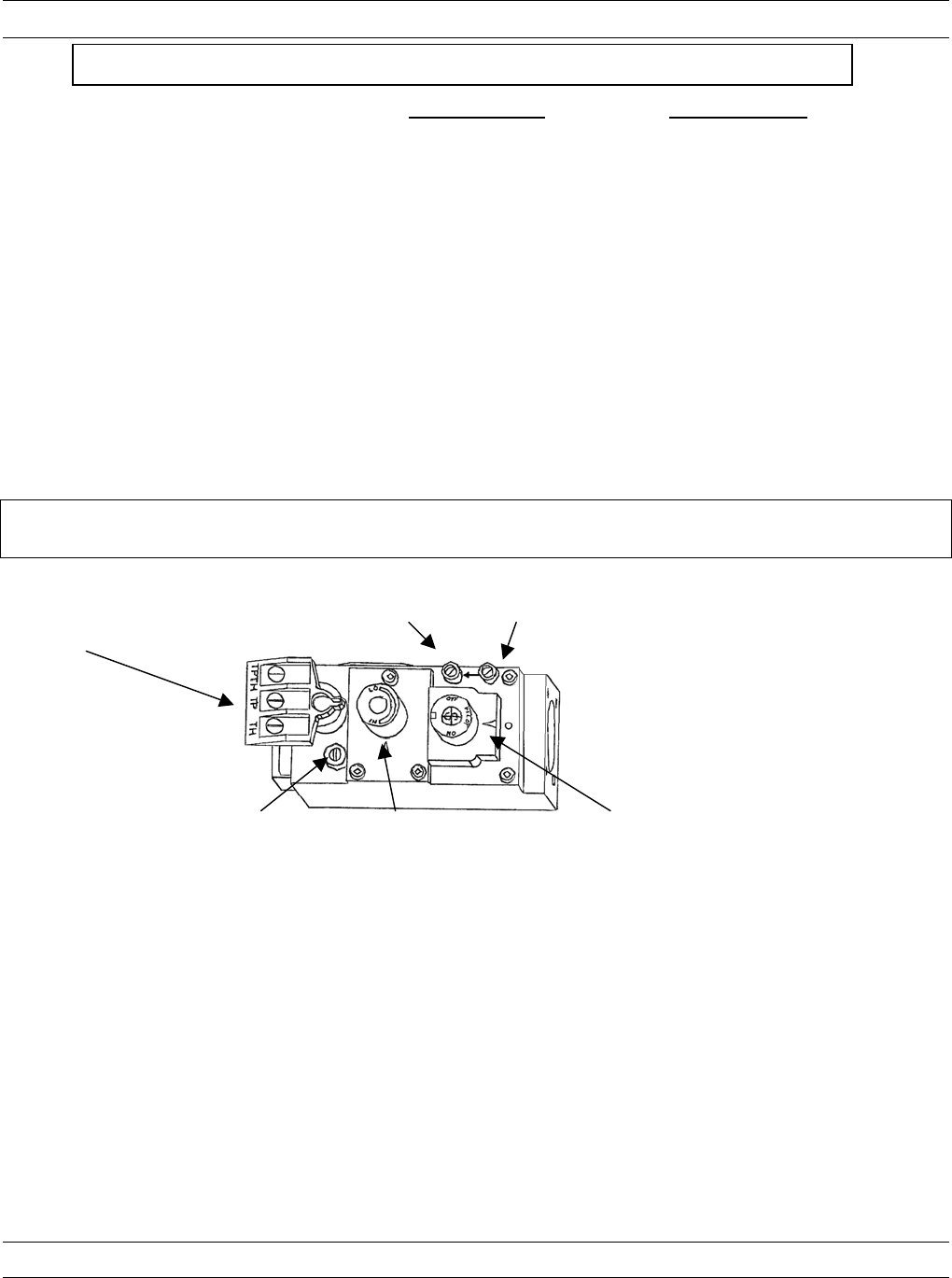

Manifold Pressure Tap. Inlet Pressure Tap.

Millivolt Terminals

Pilot Adjustment screw. "HI-LOW" Burner Gas Knob. Pilot "ON-OFF" Gas Knob.

The appliance and its shutoff valves must be disconnected

from the gas supply piping system during any pressure

testing where the pressure exceeds 1/2 PSIG (3.45 kPa)

or damage will occur to the valve.

The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.5

kPa).

When using copper or flex connectors use only fittings

approved for gas connections.

TO TEST

The pressure taps are located in the top right corner on

the valve face (right - inlet, left - manifold pressure).

• Turn set screw counter clockwise to loosen, 2 turns.

• Place 5/16" hose over pressure tap system.

• When finished, release pressure, remove hose &

tighten set screw.

Always check for gas leaks with a soap and water solution

after completing the required pressure test.

NEVER USE AN OPEN FLAME FOR LEAK TESTING

ELECTRICAL

12