100402-07 Issue 0733 Page 6 of 18

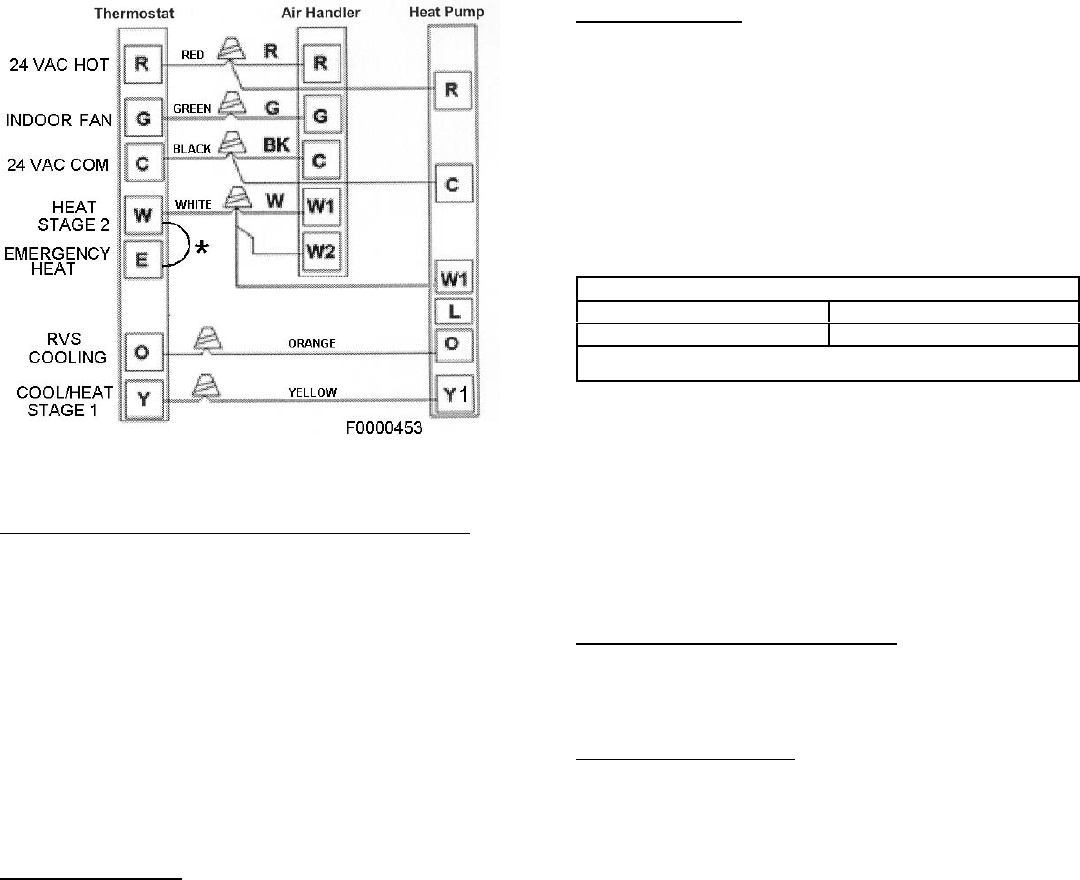

Heat Pump Application with Electric Heat

Emergency Heat (heating heat pump)

If selector switch on thermostat is set to the emergency

heat position, the heat pump will be locked out of the

heating circuit, and all heating will be electric heat ( if

applicable). A jumper should be placed between W and E

on the thermostat so that the electric heat control will

transfer to the first stage heat on the thermostat. This will

allow the indoor blower to cycle on and off with the electric

heat when the fan switch is in the AUTO position.

* Add Jumper on Subbase (Optional)

Start-Up Procedure

1. Check to ensure:

! Service valve and gage port caps are installed and

tightened.

! Voltage supply at unit agrees with nameplate

rating.

! Field wiring connections are tight and factory

wiring has not been disturbed and are tight.

! Indoor fan motor is on correct speed tap.

2. Set thermostat selector switch to OFF and fan control

switch to "Auto" is so equipped.

3. Close electrical disconnects to energize system.

4. Set room thermostat at desired temperature. Be sure

set point is below indoor ambient temperature.

5. Set the system switch of the thermostat on COOL (or

HEAT if applicable) and fan switch for continuous

operation (ON) or AUTO, as desired. There will be a

5 minute short cycle compressor delay on startup.

Operate unit for 15-20 minutes, then check the system

refrigerant charge.

6. Adjust refrigerant charge per "Adjusting Charge"

section.

Adjusting Charge

Factory charge is shown on the rating label located on

the access panel.

All split system heat pumps are factory charged for

15 feet of connecting line set and matched indoor fan

coil. Nameplate refrigerant charge should initially be

adjusted for line set lengths other than 15 feet. For line

sets shorter than 15 feet in length, remove charge. For line

sets longer than 15 feet, add charge. Oil charge is

sufficient for all line lengths.

Before final adjustment is made to the refrigerant charge,

it is imperative that proper indoor airflow be established.

Airflow will be higher across a dry coil versus a wet coil.

Blower charts are calculated with a dry or wet coil basis.

Recommended airflow is 350-450 CFM per ton (12,000

Btuh) through a wet coil. Refer to indoor unit instructions

for methods of determining air flow and blower

performance.

Cooling Cycle Charge Adjustment

The optimum method for checking the charge is by

weight. However the following methods may be used

to confirm the proper charge:

Units with Indoor Pistons

Units installed with indoor pistons require charging with

the superheat method.

The following procedure is valid when indoor airflow is

within ± 20% of its rated CFM.

1. Operate unit a minimum of 10 minutes before

checking charge.

2. Measure suction pressure by attaching a gage to

suction valve service port. Do not use compressor

suction port. Determine saturation temp from T/P

chart.

3. Measure suction temperature by attaching an

accurate thermistor type or electronic thermometer

to suction line at service valve.

4. Calculate superheat (measured temp. — saturation

temp.).

5. Measure outdoor air dry-bulb temperature with

thermometer.

6. Measure indoor air (entering indoor coil) wet-bulb

temperature with a sling psychrometer.

7. Compare superheat reading at service valve with the

chart located on control box cover.

8. If unit has a higher suction line temperature than

charted temperature, add refrigerant until charted

temperature is reached.

9. If unit has a lower suction line temperature than

charted temperature, reclaim refrigerant until charted

temperature is reached.

Refrigeration Charge Adjustment

Liquid Line Diameter Oz. Per Linear Foot *

3/8" .6

* Factory charge for series is for 15' (ft.) line sets and matched fan

coil.