4

55951

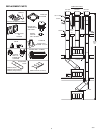

Figure 8

10 FOOT RULE

2' MIN.

2' MIN.

LEVEL OF FLUE

GAS OUTLET

10'

3' MIN.

3' MIN.

10'

OR LESS

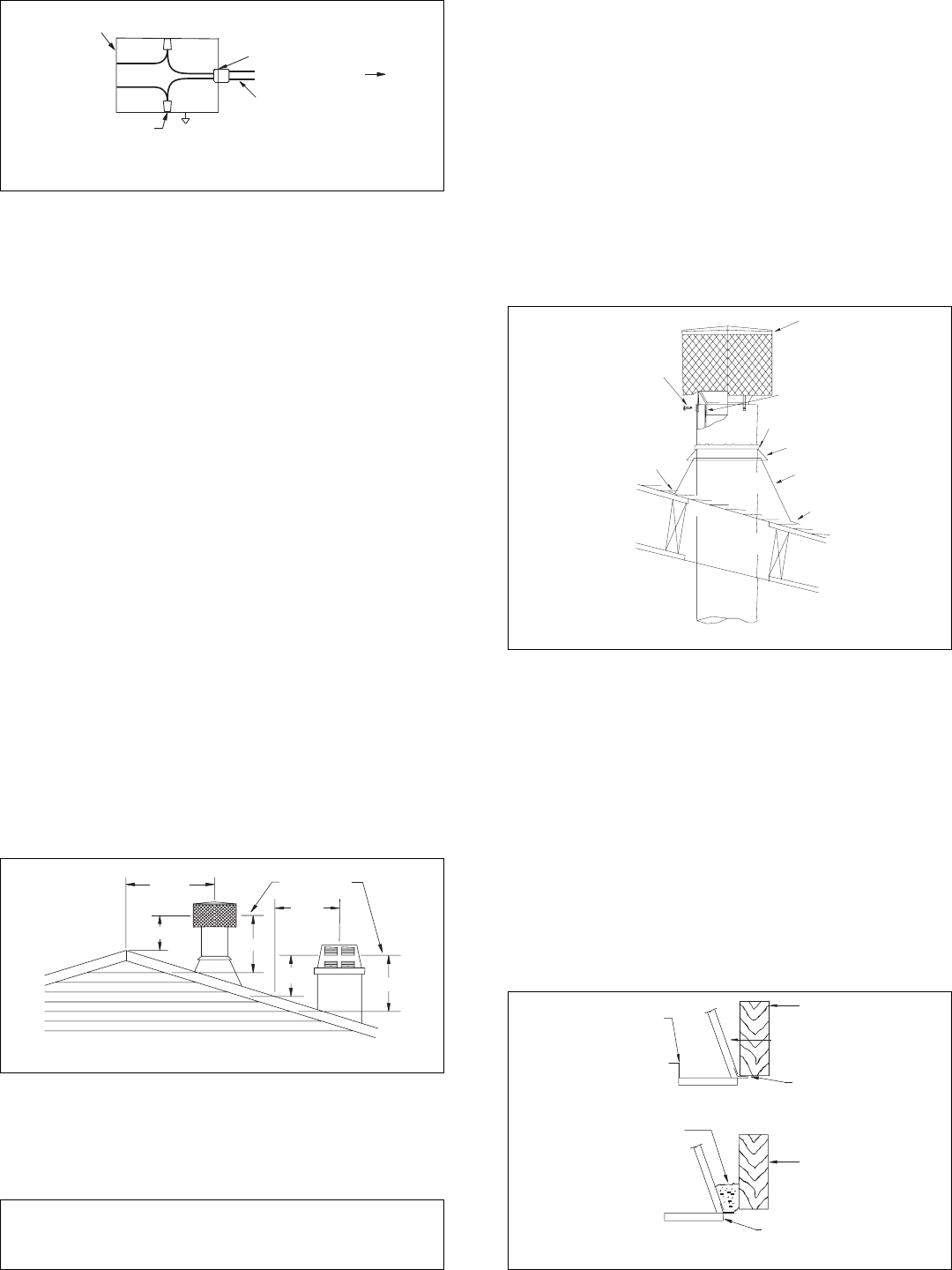

ATTACH BRACKET

TABS TO OUTER

PIPE (3 PLACES)

SECURE WITH

SCREWS

OVERLAP

SHINGLES

TOP AND SIDES

CRTL-8DM

FLUE PIPE OF CRTL-8DM

INSIDE INNER PIPE OF

CHIMNEY

CAULK

COLLAR

FLASHING

UNDERLAP SHINGLES

BOTTOM ONLY

Figure 9

PENETRATING THE ROOF

To maintain a 2-inch clearance to the pipe on a roof with a pitch, a

rectangular opening must be cut.

STEP 1: Determine the center point through which the pipe will

penetrate the roof.

STEP 2: Determine the pitch of the roof. Pitch is the distance the roof

drops over a given span, usually 12 inches. A 6/12 pitch means that

the roof drops 6 inches for each 12 inches measured horizontally.

STEP 3: From the center point determined in STEP 1, measure an

opening 17

1

/4 inches wide (8

5

/8 inches to each side of the center

point). For a roof pitch between 0/12 (flat) and 6/12, measure an

opening 21 inches long (10

1

/2 inches above and below the center

point).

6/12 to 12/12 pitches: Measure 26 inches (13 above and below).

12/12 to 18/12 pitches: Measure 32

1

/2 inches (16

1

/4 above and below).

18/12 to 24/12 pitches: Measure 40 inches (20 above and below).

STEP 4: Remove the roofing around the opening measured and cut

out this section.

STEP 5: Add the next sections of pipe until the end penetrates the

roof line. Check to see that proper clearances are maintained. Extend

chimney by adding sections of double wall pipe until pipe is a

minimum of 30 inches above highest point of roof cutout. Termina-

tion and chimney must extend a minimum of 36 inches above highest

point where it passes through roof.

10 FOOT RULE

All chimney terminations must extend a minimum of 3 feet in height

above the highest point where it passes through the roof and must be

at least 2 feet above the peak of the roof if within a horizontal distance

of 10 feet from the peak (see Figure 8).

TERMINATIONS

The fireplace and chimney system must be vented to the out-of-doors

and must be terminated with the listed round top or chase termina-

tions. If a chase termination is desired, refer to the instructions

supplied with the termination.

WARNING: Do not seal ventilation openings on the

rooftop flashing. Follow the installation instructions

provided with the termination being used.

FOR ROUND TOP TERMINATION ON ROOF

STEP 1: Slide the flashing over the pipe (no firestop is needed at the

roof level). Tack the flashing down at the top two corners with

roofing nails. Lay roofing over the top and sides of the flashing and

secure them to the roof through the flashing with roof nails. Place

roofing under the lower edge and secure to the roof.

Cover all nail heads with mastic or roof cement.

STEP 2: Install the storm collar on double wall chimney, push collar

down to flashing and seal (see Figure 9).

STEP 3: Place the CRTL-8DM on to the pipe end as illustrated and

secure with the screws provided.

IMPORTANT:

If an exposed portion of chimney is greater than 5

feet above the roof line, use support wires to keep chimney secure.

The support wires may be attached to the outer pipe of the chimney

with screws, provided the screws are no longer than 3/4".

FIREPLACE ENCLOSURE: COLD CLIMATE

INSTALLATIONS

Before finishing the enclosure around the fireplace, inspect all joints

around the fireplace. Any gaps between the nailing flanges and the

framing should be sealed with noncombustible insulation or caulking (see

Figure 10). Inspect the fireplace joints for possible gaps caused by

shipping or mishandling during installation. These should be sealed with

noncombustible materials. If the fireplace is mounted on a raised platform

insulate below the platform to prevent the entry of cold air through the

fireplace bottom by means of conduction. The above steps are import

especially if the fireplace is installed in cold weather climate. The opening

around the base of the chimney must remain open and free to circulate

outside air for keeping the chimney cool as designed (see Figure 3B, page

3). The fireplace must be set on a continuous platform to prevent cold air

from conducting through the metal bottom. The platform bottom may be

constructed of any wood product or other materials such as cement.

FIREPLACE

SIDE FRAME

FIREPLACE

SIDE FRAME

NORMAL FRAMING

PACK

INSULATION

HERE

WIDE FRAMING

SIDE

FRAMING

SIDE

FRAMING

3/4 CLEARANCE

NOT REQUIRED

AT THE FRAMING

CAULK HERE

Figure 10

10', 14 GA. W/GROUND

ROMEX ADDED TO U.L.

LISTED (MM11306)

FIREPLACE AT THE

FACTORY

COVER PLATE WITH

STRAIN RELIEF

TO WALL SWITCH

EXISTING “J” BOX

IN FIREPLACE

WIRE NUT (TYP.)

Figure 8