17

099618

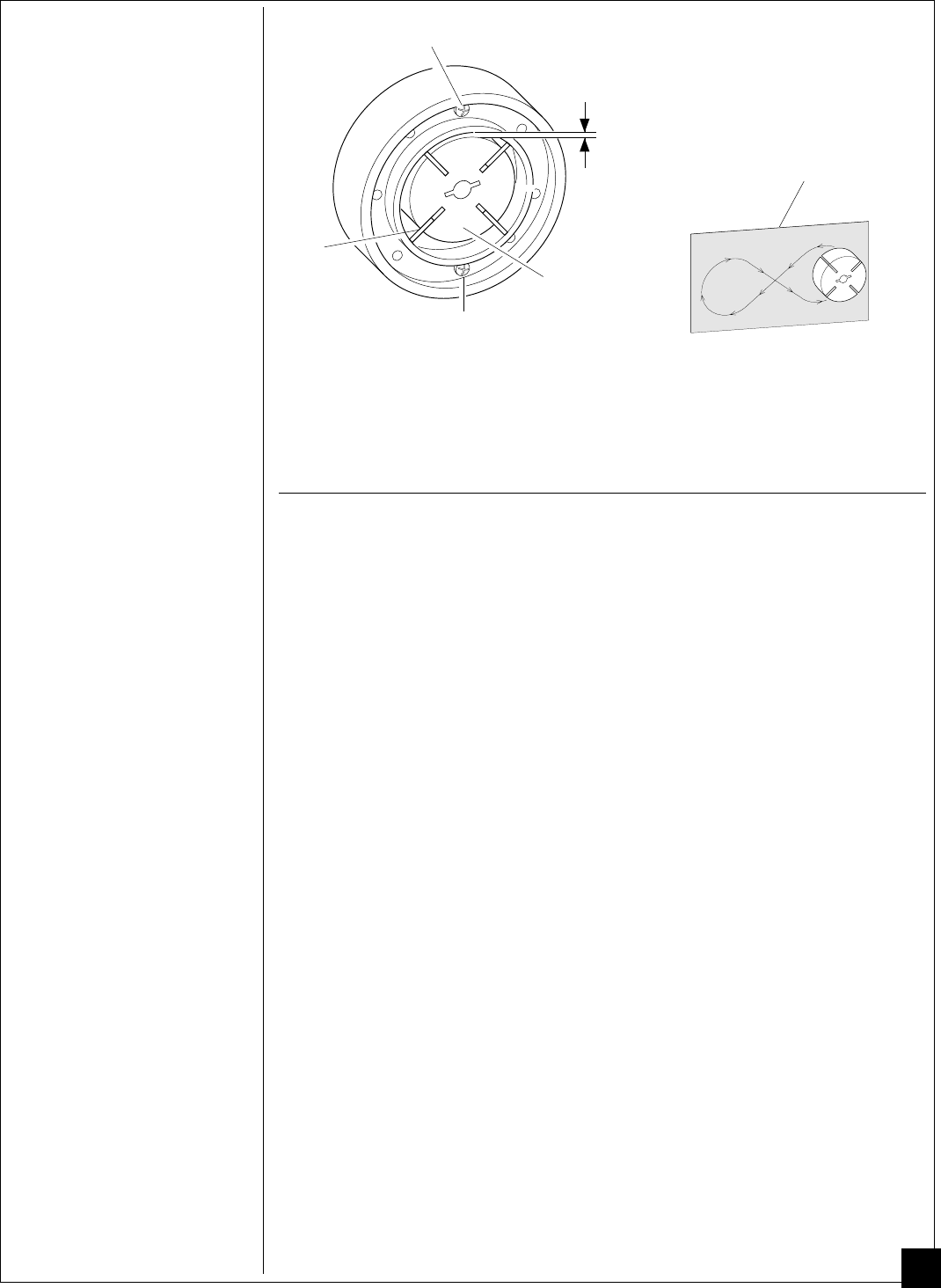

13.Perform steps 1 thru 6 (see

page 16).

14.Place fine grade sandpaper

(600 grit) on flat surface.

Sand rotor lightly in “figure

8” motion four times (see

Figure 30).

15.Reinstall insert and rotor.

16.Perform steps 10 thru 12 (see

page 16).

Figure 29 - Gap Adjusting Screw Locations

Gap Adjusting Screw

Rotor

Sandpaper

Figure 30 - Sanding Rotor

Model Size 35 50 70 100 150

Output Rating (Btu/Hr) 35,000 50,000 70,000 98,000 150,000

Fuel Use Only Kerosene or No. 1 Fuel Oil

Fuel Tank Capacity

(U.S. Gal./Liters) 3/11.3 4/15.1 5/18.9 9/34 13.5/51

Fuel Consumption

(Gal. Per Hr/Liters Per Hr) .26/.98 .37/1.40 .5/1.89 .74/2.80 1.12/

4.24

Nozzle Spray Angle 50° 50° 50° 60° 60°

Nozzle Spray Pattern Solid Cone (All Models)

Electric Requirements 120 V/60 HZ (Same All Models)

Amperage (Normal Run) 1.7 2.0 2.3 3.2 4.4

Motor RPM 1725 1725 3450 3450 3450

Hot Air Output (CFM) 165 165 253 481 500

SPECIFICATIONS

Blade

.003"/.004" (.076-.101 mm)

Gap Measured With

Feeler Gauge

Gap Adjusting Screw