2

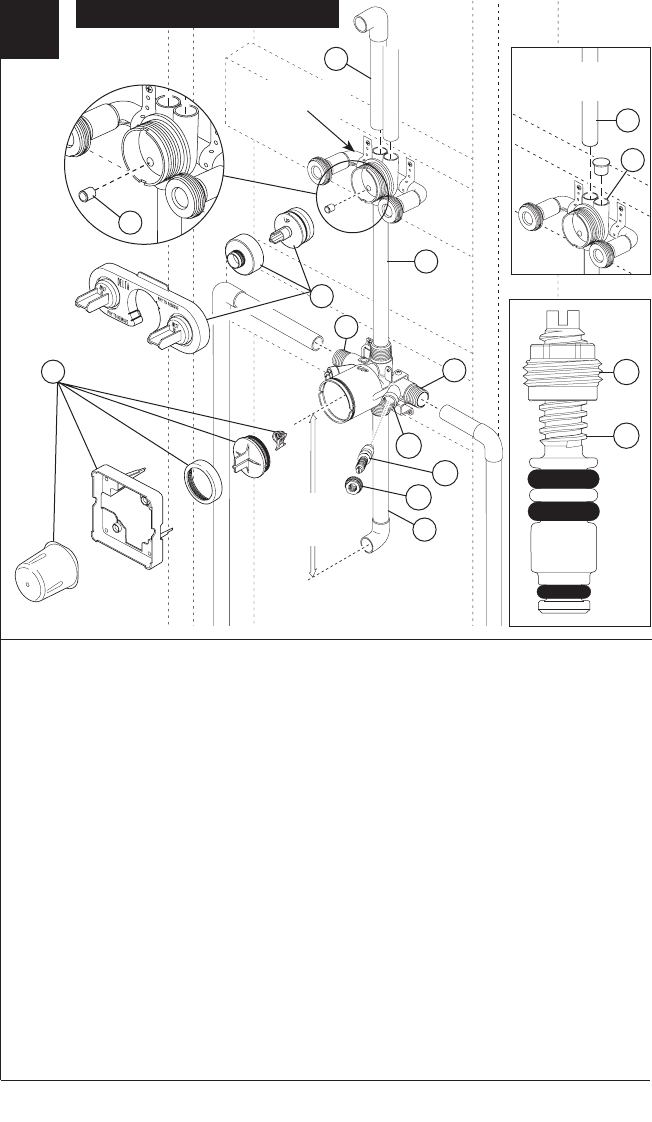

R18442 & R18442-WS Installation

Remove the bonnet nut, cartridge and

plasterguard (1), plus, the screen, test cap,

bonnet nut, plasterguard and cover (2) before

soldering. Connect valve body to water

supplies using the prop

er fittings. Note: (3)

is the cold inlet port and (4) is the hot

inlet port.

Solder a copper tube (5) from the valve

body to the jet module so the jets are at the

desired height. Determine whether a three

or six function configuration is desired. For

2 port, 3 function; solder plug into auxiliary

port (6) in casting. Solder tube (7) into the

main port of the jet module to the shower

arm elbow to the desired height. For 3 port,

6 function; all outlet ports are used. It is

recommended to mount valves to stringers

as shown.

The pipe (8) between valve & tub spout must

be a minimum of 1/2" (13 mm) copper pipe

or 1/2" (13 mm) iron pipe in a straight drop

no less than 8" (203 mm) but no more than 16"

(406 mm) long with only one 90 degree elbow

to the spout nipple. If any outlet port is to be

unused, seal the port with a pipe plug.

If you are making a back to back or reverse

installation (hot on right and cold on left) install

the valve body as described, but reverse the

water supply lines.

After soldering press the detent (9) into proper

hole as shown, reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (10) on stem (11) as shown.

Then press stem and nut assembly into body

(12) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

R18442 & R18442-WS

2 Port, 3 Function

Installation

3 Port, 6 Function

Installation

1

2

3

4

9

8

6

7

7

5

16"

(406 mm)

Max

11

10

12

10

11

5