9

Models 2E510D, 2E511D, 3E218D, and 3E219C

Dayton Operating Instructions and Parts Manual

101421

®

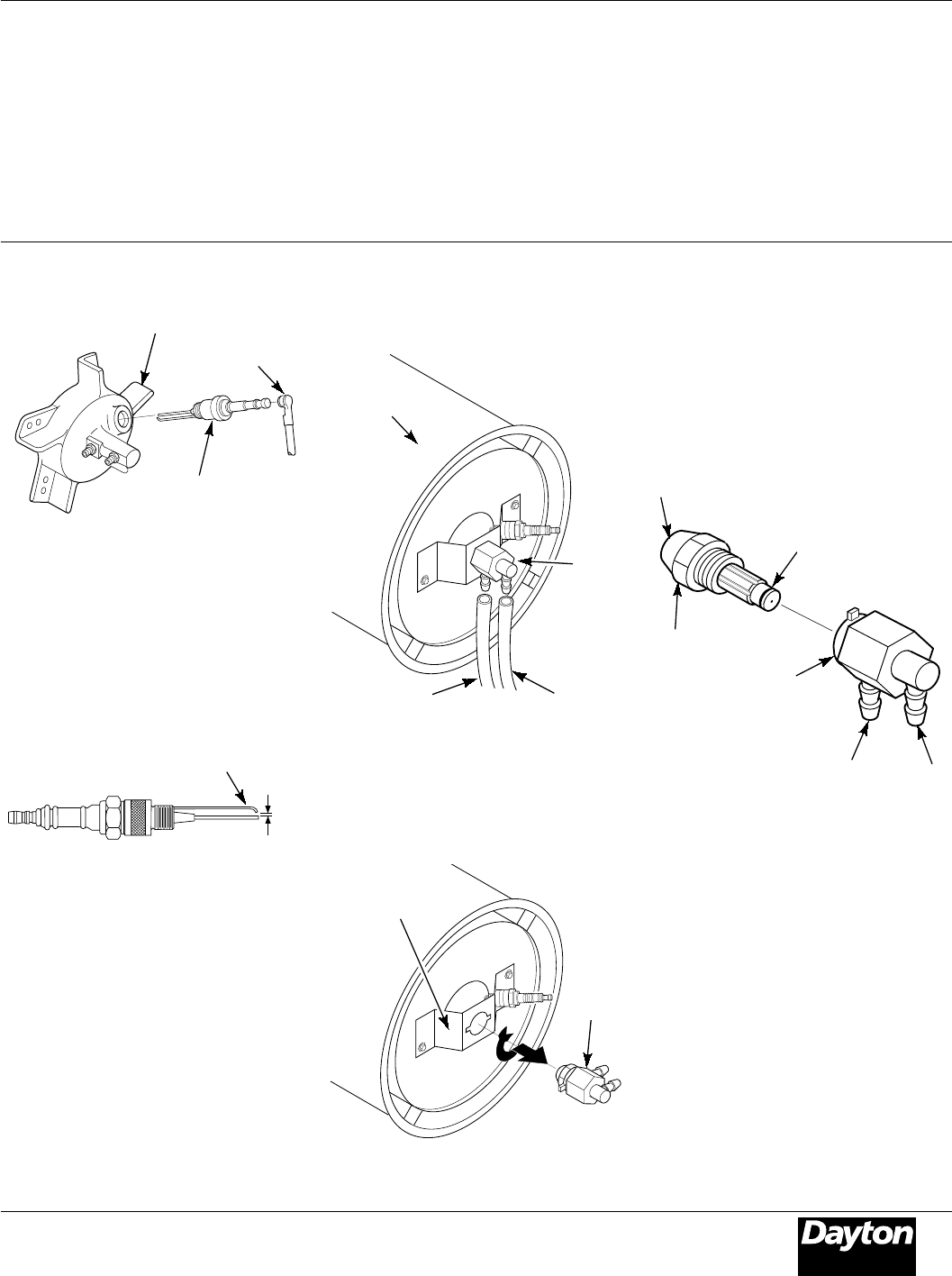

Spark Plug

Wire

Spark Plug

Burner

Head

Figure 22 - Spark Plug Removal, Models

3E218D and 3E219C

Maintenance (Continued)

5. Clean and regap spark plug elec-

trodes to .075" gap.

6. Install spark plug in burner head.

7. Attach spark plug wire to spark plug.

Bend Here

to Adjust

Gap

Figure 23 - Spark Plug Gap, Models

3E218D and 3E219C

8. Replace fan (see page 6).

9. Replace fan guard and upper shell.

NOZZLE

(Models 2E510D and 2E511D)

1. Remove upper shell (see page 6).

2. Remove fan (see page 6).

3. Remove fuel and air line hoses from

nozzle assembly.

Figure 25 - Removing Nozzle Assembly,

Models 2E510D and 2E511D

Nozzle

Assembly

Burner Strap

Figure 24 - Removing Air and Fuel Line

Hoses, Models 2E510D and 2E511D

Fuel Line

Hose

4. Turn nozzle assembly 1/4 turn to

left and pull toward motor to

remove (see Figure 25).

5. Place plastic hex-body into vise and

lightly tighten.

6. Carefully remove nozzle from the

nozzle adapter using 5/8" socket

wrench.

Air Line

Fitting

Fuel Line

Fitting

Nozzle

Nozzle

Sleeve

Nozzle

Face

Figure 26 - Nozzle and Nozzle Adapter,

Models 2E510D and 2E511D

7. Blow compressed air through face

of nozzle. This will free any dirt in

nozzle area.

8. Inspect nozzle sleeve for damage.

9. Replace nozzle into nozzle adapter

until nozzle seats. Tighten 1/3 turn

more using 5/8" socket wrench (40-

45 inch-pounds).

10. Attach nozzle assembly to burner

strap.

11. Attach fuel and airline hoses to

nozzle assembly.

12. Replace fan (see page 6).

13. Replace fan guard and upper shell.

Combustion

Chamber

Nozzle

Assembly

Air Line

Hose

Nozzle Adapter

.075

Gap