5

III Before Installing

Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in 1)

strict accordance with this manual and the authority having jurisdiction.

In the absence of an authority having jurisdiction, installation must be in accordance with this manual •

and the National Fuel Gas Code, ANSI Z223.1.

Where required by the authority having jurisdiction, this installation must conform to the • Standard for

Controls and Safety Devices for Automatically Fired Boilers (ANSI/ASME CSD-1).

Read Section VII to verify that the maximum combustion air and exhaust pipe lengths will not be 2)

exceeded in the planned installation. Also verify that the vent terminal can be located in accordance with

Section VII.

Make sure that the boiler is correctly sized:3)

For heating systems employing convection radiation (baseboard or radiators), use an industry a)

accepted sizing method such as the I=B=R Heat Loss Calculation Guide (Pub. #H21 or #H22)

published by the Hydronics Institute in Berkeley Heights, NJ.

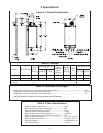

In sizing the boiler take into consideration the following boiler water fl ow/temperature limitations:b)

Maximum regulated supply temperature is 176F•

Maximum fl ow through the boiler is approximately 5.5GPM. •

Minimum boiler temperature rise is approximately 37F at high fi re. •

For new radiant heating systems, refer to the radiant tubing manufacturer’s boiler sizing guidelines. c)

For combi boilers make sure that the domestic hot water fl ow rate shown in Table 2.2, will be d)

adequate to meet the peak demand for domestic hot water.

Make sure that the boiler received is confi gured for the correct gas (natural or LP).5)

Make sure that the boiler is confi gured for use at the altitude at which it is to be installed. 6)

IV Locating the Boiler

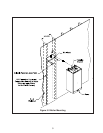

Observe the minimum clearances shown in Figure 4.1. These clearances apply to both combustible and 1)

non-combustible materials.

Note the recommended service clearances in Figure 4.1. These service clearances are recommended, 2)

but may reduced to the combustible clearances provided:

Access to the front of the boiler is provided through a door•

Access is provided to the condensate trap located underneath the boiler.•

The relief valve must be installed in the factory specifi ed location.3)

The boiler should be located so as to minimize the length of the vent system.4)

The combustion air piping must terminate where outdoor air is available for combustion and away from 6)

areas that will contaminate combustion air. Avoid areas near chemical products containing chlorine,

chloride based salts, chloro/fl uorocarbons, paint removers, cleaning solvents and detergents.

NOTICE

This product must be installed by a licensed plumber or gas fi tter when installed within the

Commonwealth of Massachusetts. See Appendix A for additional important information about

installing this product within the Commonwealth of Massachusetts.

Natural Gas and Propane Installation Code.

The boiler must not be installed on carpeting.5)

/NFPA 54 and/or CAN/CSA B 149.1