39

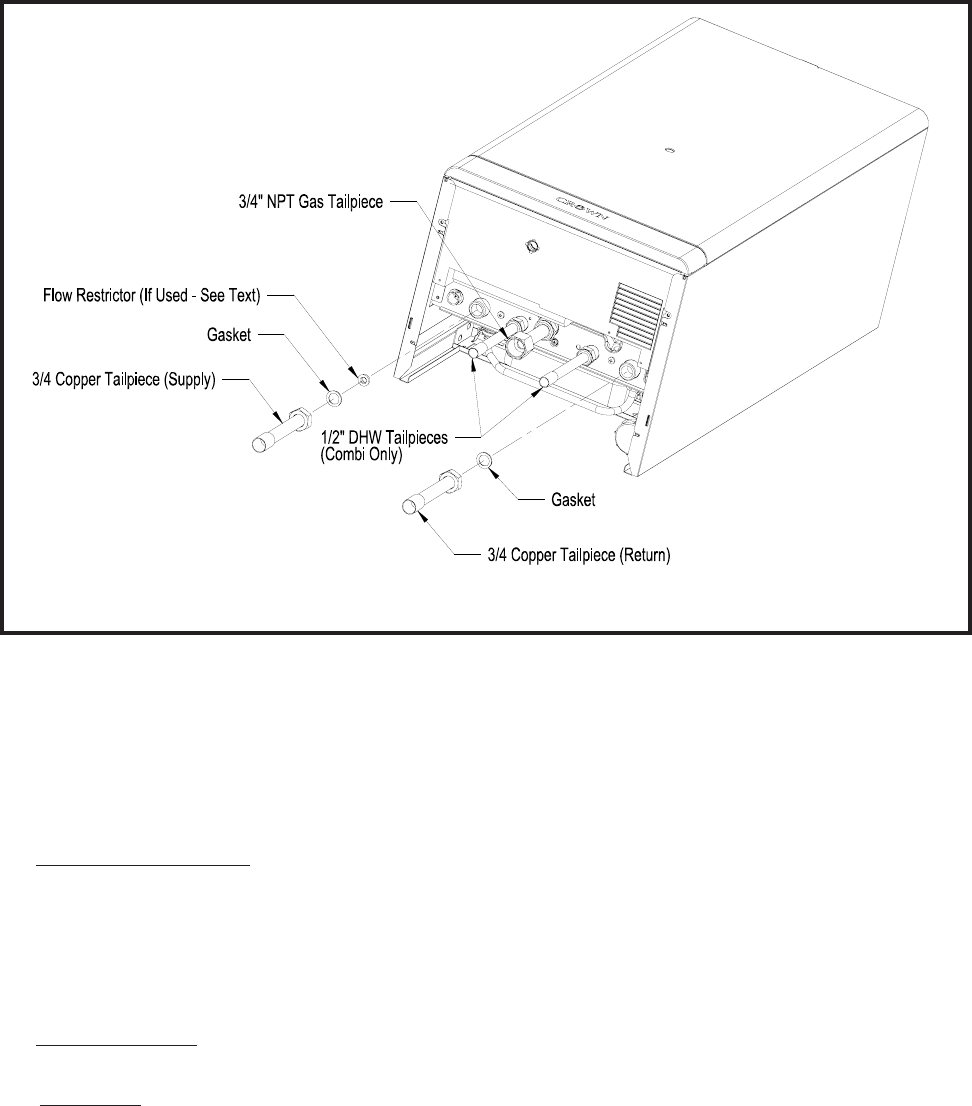

Figure 9.4: Supply And Return Tailpiece Installation

C. Piping for Special Situations

Certain types of heating systems have additional requirements. Some examples follow:

Primary-Secondary Piping1) – Primary-secondary piping is required when circulator zoning is used or when the

system fl ow rate must be greater than 5.5

GPM. In these cases, the piping shown in Figure 9.5 is used so that the

fl ow through the system is completely independent of the fl ow through the boiler. This ensures reliable operation of

the boiler’s fl ow switch.

When assembling the piping shown in Figure 9.5, be sure to observe the minimum dimensions shown. The

minimum pipe size of the primary piping in the vicinity of the tees is 1 1/4”. At least 11” (8 diameters) of 1-1/4”

straight pipe must be installed upstream of the tees as shown. At least 5 1/2” (4 diameters) of 1-1/4” straight pipe

must be installed downstream of the tees.

Piping with a Chiller2) – If the boiler is used in conjunction with a chiller, pipe the boiler and chiller in parallel as

shown in Figure 9.6. Use isolation valves to prevent chilled water from entering the boiler.

3) Air Handlers – Where the boiler is connected to air handlers through which refrigerated air passes, use fl ow control

valves in the boiler piping or other automatic means to prevent gravity circulation during the cooling cycle.

D. Internal Boiler Piping

Schematics of the internal boiler piping are shown in Figures 9.7 and 9.8 for the MWC116E*T (combi) and

MWC116E*L (heat-only) models respectively. A schematic of the internal domestic hot water piping for the MWCE*T is

shown in Figure 10.3.