LOCATIONS

1. This furnace must be installed on an outside wall and vented

to the outside. If possible, this wall should be on the side of

the house that receives the least amount of wind since strong

gusting winds could cause pilot outage.

2. For most efficient performance, locate furnace as centrally

as possible in the area to be heated.

3. The furnace can be installed flush against a wall or recessed

up to 10” maximum. For proper combustion, make sure

unit is level front to back and side-to-side.

4. Do not install the furnace in a closet, alcove or small hallway

where the furnace could be isolated from the space to be

heated by closing a door.

5. Be sure the vent cap will have the proper clearances (See

Figure 2).

6. Check inside the wall to make sure there are no obstacles

such as water pipes, electric wiring, etc. which could

interfere with the installation of the furnace or vent tubes.

7. Be sure to maintain adequate accessibility clearances for

servicing and proper operation.

8. If the furnace is installed in a basement, a 12” clearance

must be maintained between ground level and the bottom

of the vent cap. Do not install furnace where vent cap will

terminate in a window well or any other opening below

ground level.

INSTALLATION

ELECTRICAL ROUGH-IN

For convenience, this furnace is equipped with a three-prong

power cord located on the top left of heater. The 115V wiring

should be brought in on the left side terminating in a receptacle

box (not provided). Consult local codes or ordinances. (For

Amps, see Page 2/Specifications and Dimensions).

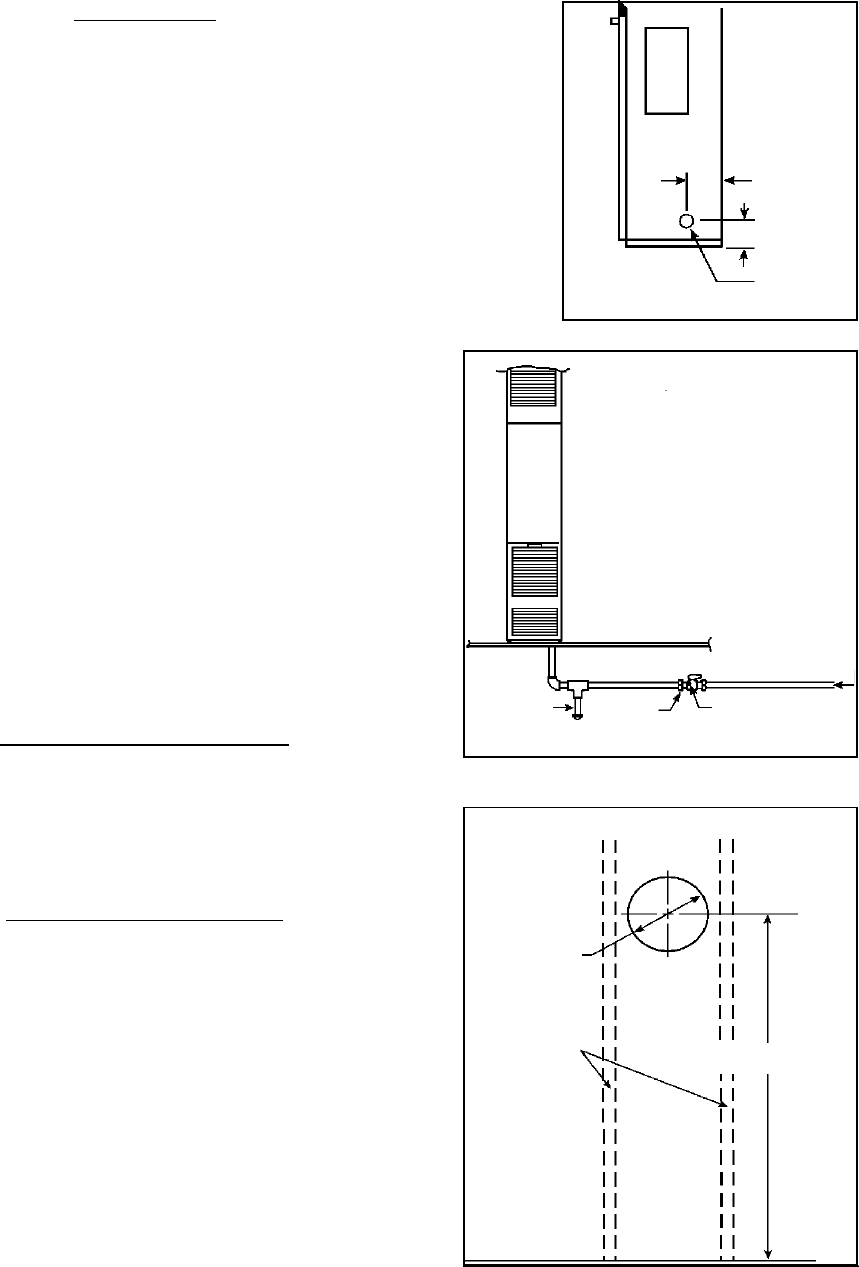

ROUGH-IN GAS SUPPLY

Install a 1/2 inch diameter gas supply line. The gas line can

enter the cabinet through the right side or bottom (See Figure

3). The gas line must have an individual manual shut off valve.

Also, you must install a drip leg and provide a 1/8” N.P.T.

plugged tapping, accessible for test gauge connection,

immediately upstream of the gas supply connection to the

furnace (See Figure 4).

The furnace and its individual shut off valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of ½

psig (3.5kPa). The furnace must be isolated from the gas supply

piping system by closing its individual manual shut off valve

during any pressure testing of the gas supply piping system at

test pressures equal to or less than ½ psig (3.5kPa).

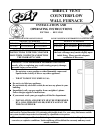

3-1/2”

2-5/8”

1-1/2 OA

FIGURE 3

Gas

Supply

Line

Drip

Leg

Manual

Cut Off

Valve

1/8 N.P.T.

Pressure Tap

FIGURE 4

Page 6

FIGURE 5

9-1/4

DIA.

WALL

STUDS

DVCF40 - 59”

DVCF55/65 - 68-1/2”

FINISHED

FLOOR