15

Stardance Direct Vent/Natural Vent Gas Heater

20007065

Install the Vent Adapter Pipe

(Simpson Dura-Vent Components)

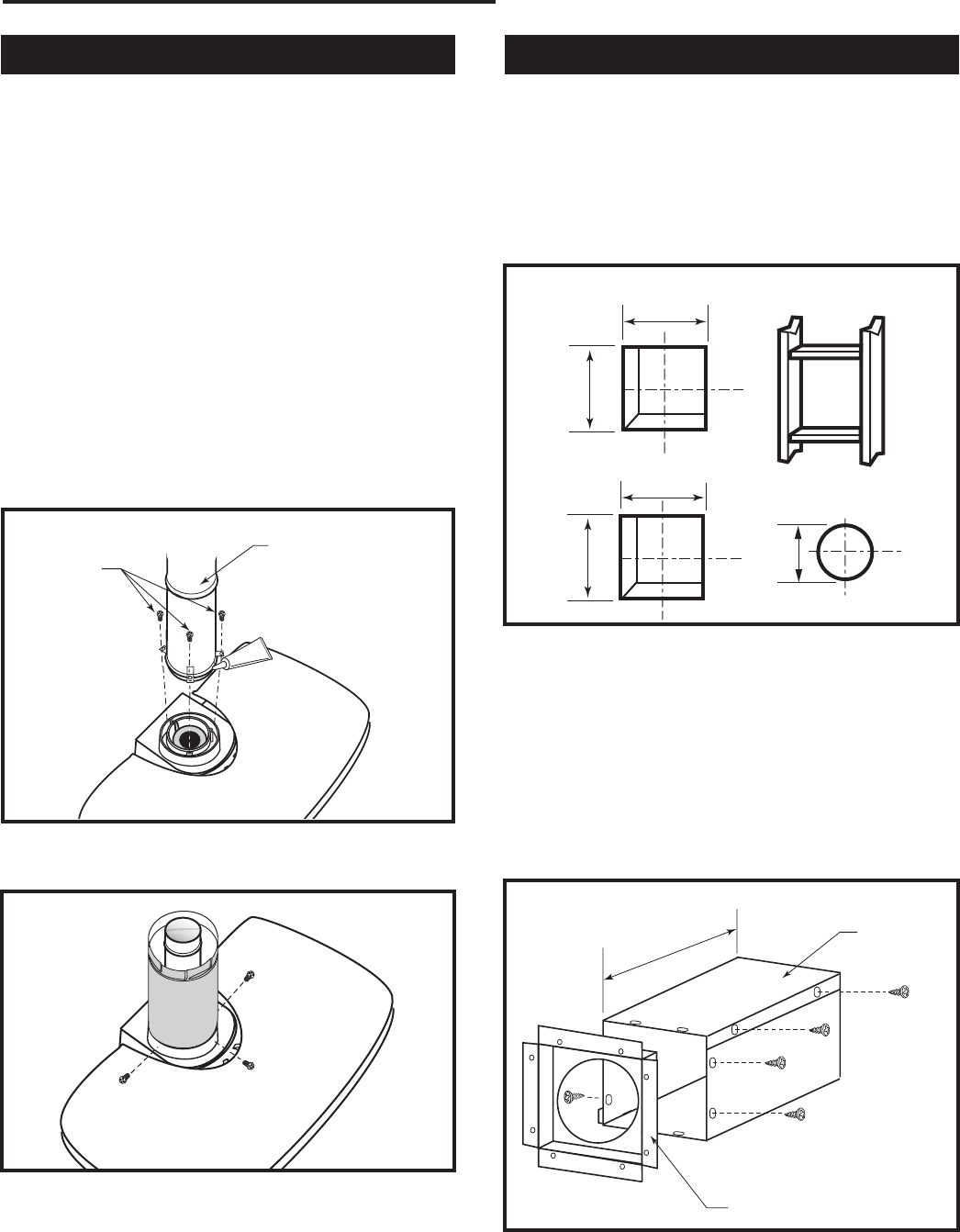

1. Install the Restrictor Plate. Consult the ‘Vent Run

Specifications’ on Page 8 to determine whether the

restrictor plate is needed. If so, put the restrictor

plate in place within the inner flue collar. (Fig. 16)

2. Discard the inner starter pipe shipped with the log-

set. Using the starter pipe assembly listed on Page

7, slide the inner section out to allow access.

• Run a bead of sealant around the bottom end of

the starter pipe and attach the assembly to the stove

using three 1/4-20 x 3/8” Phillips screws provided in

the parts bag. (Fig. 20)

3. Install the Outer Adapter Pipe. Apply a 1/4” bead of

cement around the outside surface, about one inch

from the crimped end. (Fig. 21) Orient the vertical

seam to the rear, and insert the crimped end of the

outer pipe into the flue collar. Fasten with three sheet

metal screws provided.

ST355

dura v

ent

attach inner assy

4/7/00 djt

CEMENT

1/4-20 x

3/8 Phillips

Screws

Inner Adapter

Pipe

ST355a

Fig. 20 Simpson Dura-Vent - install inner adapter pipe.

ST356

dura v

ent

attach outer assy

4/7/00 djt

ST356a

Fig. 21 Simpson Dura-Vent - install outer adapter pipe.

Side Wall Termination Assembly

1. Locate the vent opening on the wall. Refer to Fig-

ure 4, Page 6, to determine the opening centerline.

It may be necessary to first position the stove and

measure to find the hole location. Depending on

whether the wall is made of combustible materials,

cut the opening to the size shown in Figure 23. Com-

bustible wall openings must be framed as shown in

Figure 22.

VO584-100

Vent Opening

2/99 djt

CFM System

9³⁄₈”

(240mm)

9³⁄₈”

(240mm)

Combustible Wall

Framing Detail

DuraVent

System

10”

(254 mm)

7¹⁄₂”

(191 mm)

Noncombustible Wall

VO584-100

Fig. 22 Locate vent opening.

2. Measure the wall thickness and cut the wall sleeve

sections to proper length (MAXIMUM 12”). Assemble

the sleeve with the #8 sheet metal screws supplied.

Attach the firestop plate to the sleeve end with the

holes. (Fig. 23) NOTE: The wall sleeve is required

in combustible walls only.

3. Install the Wall Firestop/Sleeve assembly into the

wall cutout and fasten the firestop to the wall cutout

framing members. (Fig. 23)

ZCS103

Zero Clearance Sleeve

& Firestop

12/6/99 djt

12”

(305 mm)

Max. Length

Sleeve

#8 Sheet

Metal Screws

Firestop

ZCS103

Fig. 23 Assemble the wall sleeve and firestop.