- 11 -

Measure wall thickness and cut adjustable zero clearance

sleeve parts to proper length (MAXIMUM 12"/305mm).

Adjust sleeve to maximum (10-3/8 x 9-3/8). and attach to

firestop with #8 sheet metal screws (supplied). (Fig. 16)

Install firestop assembly.

#8

SCREWS(2)

ADJUSTABLE ZERO

CLEARANCE SLEEVE

ADJUSTABLE

ZERO CLEARANCE

SLEEVE

#8

SCREWS(2)

#8

SCREWS(2)

Maximum Length

12" (294mm)

FIRESTOP

Fig. 15

STEP 2

Fig. 16

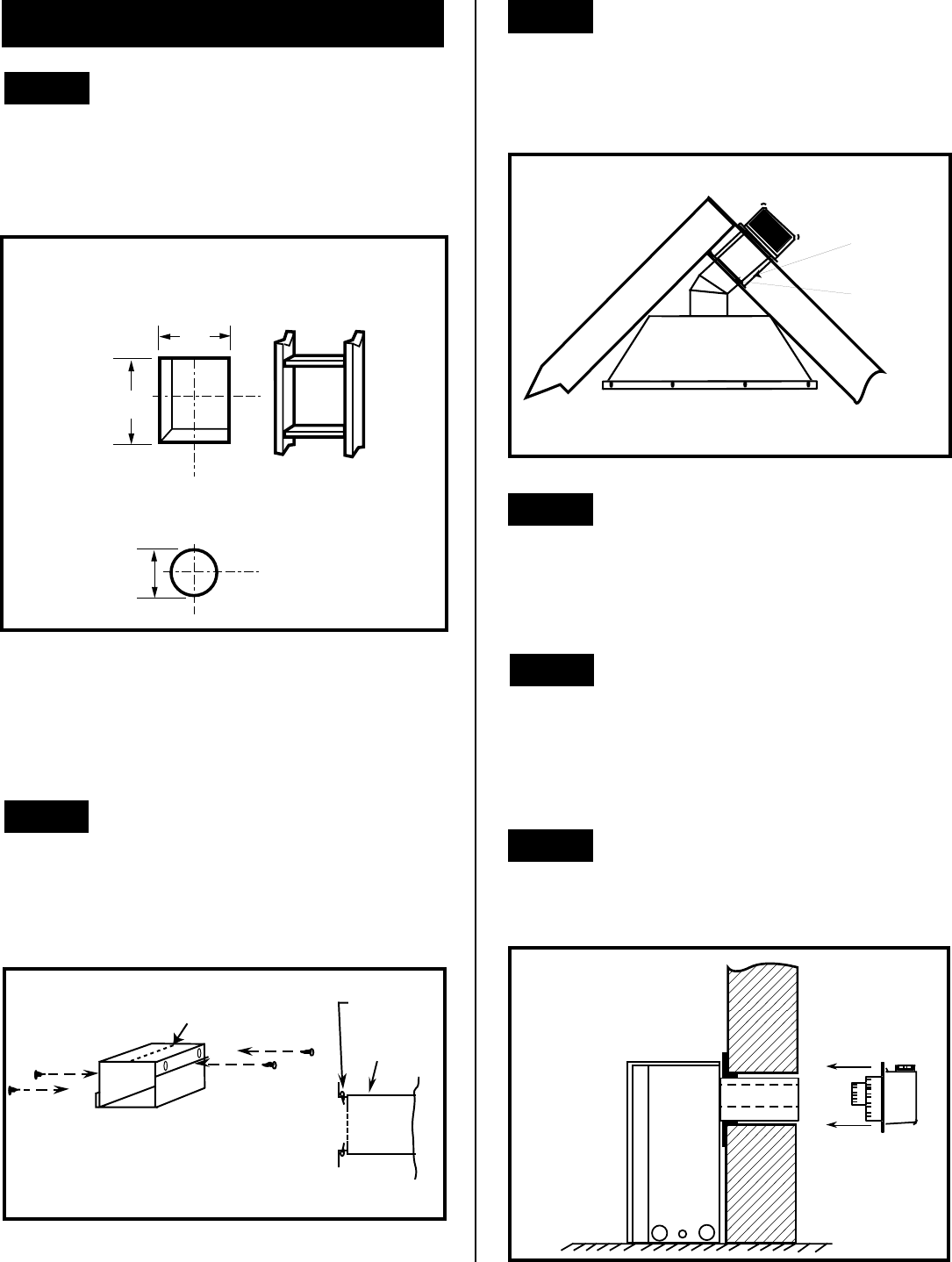

Combustible Walls. Cut a 10-3/8"H x 9-3/8"W (265mm

x 240mm) hole through the exterior wall and frame as

shown. Fig. 15.

Non-Combustible Walls: Hole opening must be 7.5"

(190mm) in diameter.

REAR WALL INSTALLATIONS

STEP 1

Locate vent opening on wall. To locate hole centre consult

with appropriate fireplace dimensions, page 4. Frame as

shown below.

(240mm)

9-

3/8

"

10-

3/8

"

(255mm)

7-

1/2

"

(190mm)

Vent Opening —

Noncombustible Wall

(framing detail)

Vent Opening —

Combustible Wall

STEP 4

Slip 4" and 7" pipes onto respective flue collars. Make sure

to fix to the fireplace collar the 4" pipe with three (3) screws

before fixing the 7" pipe on the 7" collar. Both pipes must

be on a level plane. Fig. 17.

STEP 3

Measure from fireplace collar or elbow face to face of

outside wall (add 2" for vent pipe overlap. Mark pipes and

cut to length. It is very important that the two pipes are flush

with the outside wall once the fireplace is in its final location.

STEP 5

Guide the vent termination 4" collar into the 4" pipe then the

7" collar into the 7" pipe. Do not force the venting into

position. If the pipes do not line up with the termination

collars, disassemble pipes and reattach to the fireplace

collar. (Fig. 18)

STEP 6

Secure fireplace to floor through floor holes and adjustable

frame drywall strip (nailing flange) to frame. (See Framing

& Finishing Section)

Fig. 18

Straight Out Thru the Wall Application

FINISHED

WALL

VENT

TERMINATION

FIRESTOP

ZERO

CLEARANCE

SLEEVE

Fig. 17