16

BFC36 Balance Flue Heat-Circulating Fireplace

7412647

WARNING: Hearth extension must be installed in

accordance with Figure 23 and must not cover the

bottom front opening of the circulating model.

Alternate noncombustible materials may be used pro-

viding the (total) thermal resistance (Rt value) of the al-

ternate material employed is greater than or equal to R

= 1.09 Thermal resistance (R) or thermal conductivity

(K), may be obtained from manufacturer of the material.

Factors are related by the formula K = 1/R. (Fig. 24)

T = given thickness

R = thermal resistance for a given thickness (T)

K = thermal conductivity

Noncombustible material with a lower R value may

be used, provided thickness of material is sufficiently

greater to maintain an equivalent (total) thermal resis-

tance (Rt).

COMMON MATERIALS AND FACTORS

MATERIAL K*

R

MINIMUM

THICKNESS

EH2416

Common Brick

0.458

5.0

1.09 0.50 in.**

0.10 5.46 in.**

(CFM Corporation)

R Value is for 1/2 inch.

* Units of K = BTU/SQ FT/HR/˚F/IN

** Thickness of Listed Material

FP533ADD

Addendum

6/1/99 djt

8/4/99 changed .2 to .1

one inch to 1/2 inch djt

FP533ADD

Fig. 22 Hearth extension material factors.

Example of Determining Hearth Extension

Equivalents

To determine the thickness required for any new mate-

rial:

NEW K of new material (per inch) thickness

required = --------------------------------------- X of listed

thickness K of listed material (per inch) material

Example for Common Brick

T (new) = 5.0/0.458 x 0.50 in. = 5.46 in. (new required

thickness).

FP550

BR/BC - SEALING

DETAILS

9/29/97

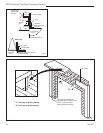

Wall Covering

Noncombustible

Decorative Fac-

ing

Seal all cracks

between fireplace

surround and wall

materials with non-

combustible material.

Noncombus-

tible Decorative

Covering

Hearth Exten-

sion Insulation

2 x 4” Header

- Do not notch at

standoffs

Seal crack between

fireplace and hearth

extension with noncom-

bustible material

Safety Strips -

Must be overlapped 1/2”

minimum

Side View

FP550

Fig. 23 Sealing gaps.

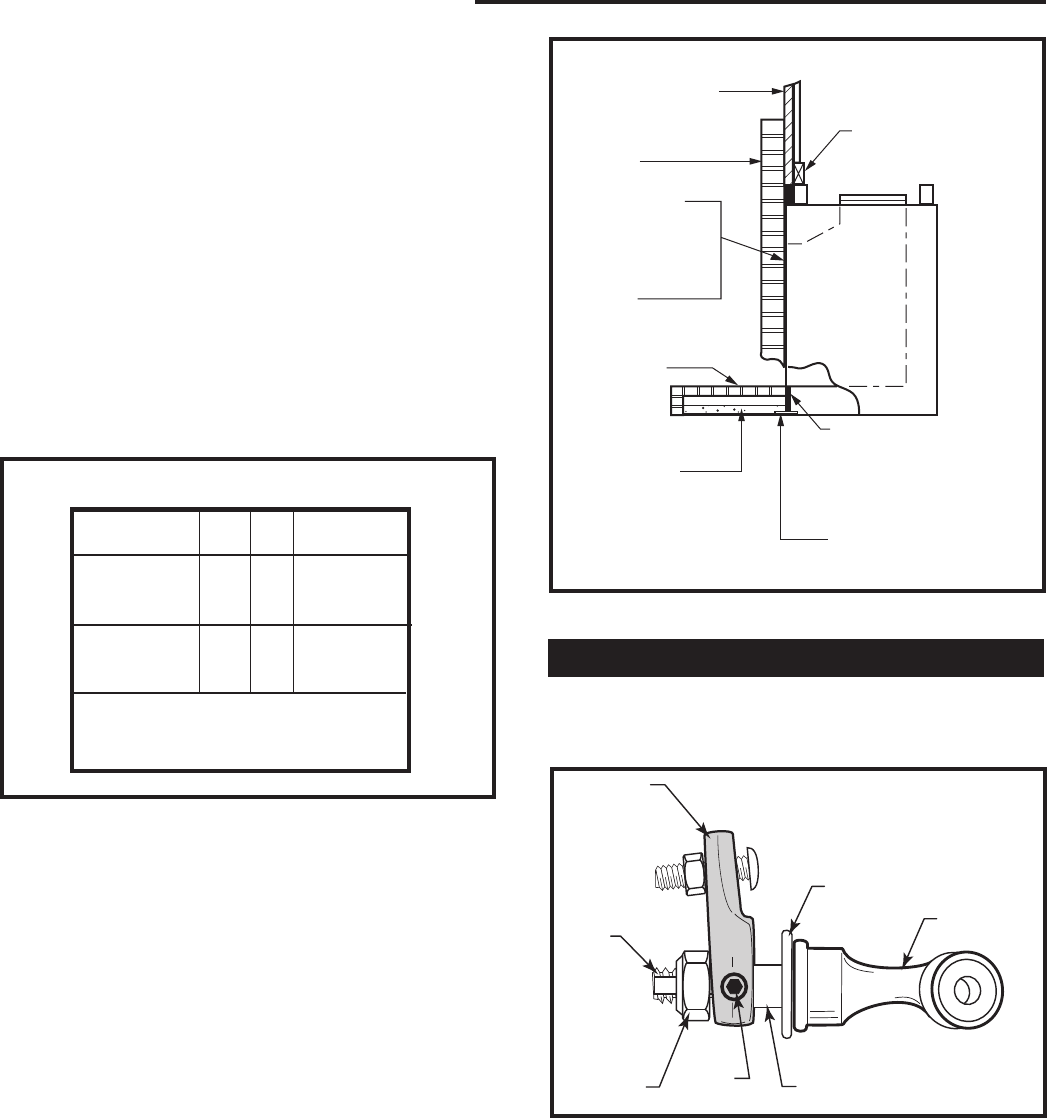

Install Door Handles

1. Remove the door handle stubs from the plastic bag.

2. Remove the large locking nut from right door handle

stub shaft. (Fig. 24)

FP1595

Door Pawl parts

11/05

Pawl

Handle

Shaft

Washer

Large

Locking

Nut

Spacer

Handle

Stub

FP1595

Fig. 24 Right door handle stub parts.

Set

Screw

3. Using 1/8” Allen wrench loosen the set screw and

remove the pawl, spacer and washer.

4. Insert handle shaft through handle opening in right

door.

5. With the handle pointing down and the flat side of

the threaded shaft facing up, replace the washer,

spacer and pawl. Be sure the door adjustment por-

tion of the pawl is on the left side of the handle stub.

Secure with large locking nut. Tighten set screw