37

START-UP

Unit Preparation —

Make sure that unit has been in-

stalled in accordance with these installation instructions and

applicable codes.

Return-Air Filters —

Make sure correct filters are in-

stalled in filter tracks. See Table 1. Do not operate unit without

return-air filters.

Compressor Mounting —

Compressors are internally

spring mounted. Do not loosen or remove compressor hold-

down bolts.

Internal Wiring —

Check all electrical connections in

unit control boxes. Tighten as required. Ensure electrical wires

do not come in contact with refrigerant tubing or sharp edges.

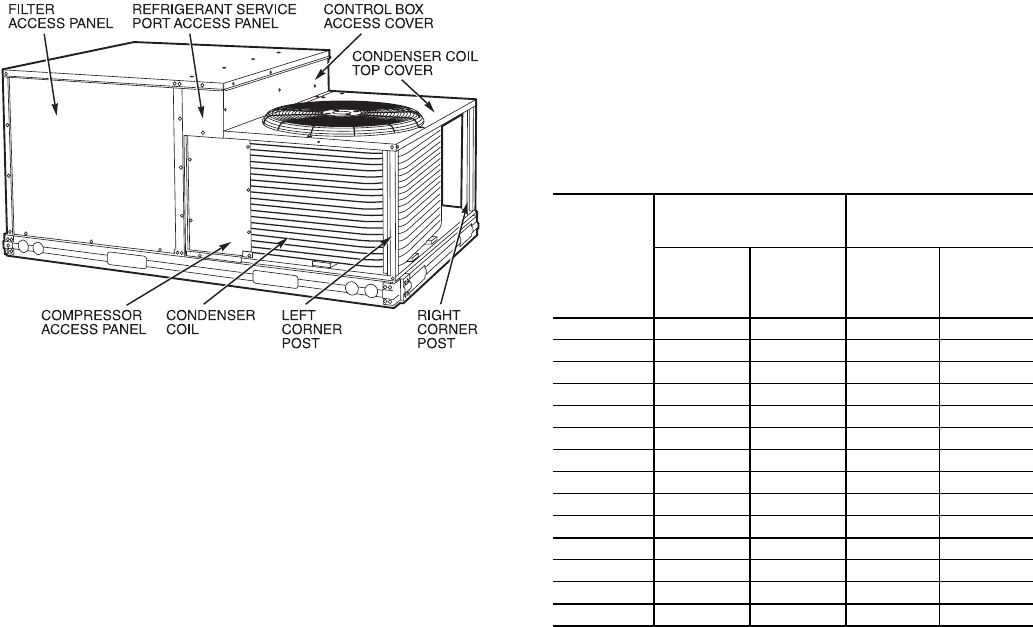

Refrigerant Service Ports —

To service refrigerant

service ports, remove refrigerant service port access panel. See

Fig. 43. Each unit system has 4 Schrader-type service gage

ports: one on the suction line, one on the liquid line, and two on

the compressor discharge line. Be sure that caps on the ports

are tight. When a controls upgrade package is used, one

Schrader-type valve is located under both the high-pressure

switch and the low-pressure switch.

High Flow Valves —

Located on the compressor hot gas

and suction tubes are High Flow Valves. Large black plastic

caps distinguish these valves with o-rings located inside the

caps. These valves can not be accessed for service in the field.

Ensure the plastic caps are in place and tight or the possibility

of refrigerant leakage could occur.

Compressor Rotation —

On 3-phase units with scroll

compressors, it is important to be certain compressor is rotating

in the proper direction. To determine whether or not compres-

sor is rotating in the proper direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the unit.

3. The suction pressure should drop and the discharge pres-

sure should rise, as is normal on any start-up.

If the suction pressure does not drop and the discharge pres-

sure does not rise to normal levels:

1. Note that the evaporator fan is probably also rotating in

the wrong direction.

2. Turn off power to the unit and install lockout tag.

3. Reverse any two of the unit power leads.

4. Reapply power to unit and recheck pressures.

The suction and discharge pressure levels should now move

to their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direc-

tion, the unit makes an elevated level of noise and does not

provide cooling.

Cooling —

Set space thermostat of OFF position. To start

unit, turn on main power supply. Set system selector switch at

COOL position and fan switch at AUTO. position. Adjust ther-

mostat to a setting below room temperature. Compressor starts

on closure of contactor.

Check unit charge. Refer to Service, Refrigerant Charge

section, page 41. Allow unit to operate a minimum of 10 min-

utes before checking charge.

Reset thermostat at a position above room temperature.

Compressor will shut off. Evaporator fan will shut off after

30-second delay.

TO SHUT OFF UNIT — Set system selector switch at OFF

position. Resetting thermostat at a position above room tem-

perature shuts unit off temporarily until space temperature ex-

ceeds thermostat setting.

Main Burners —

Main burners are factory set and should

require no adjustment.

TO CHECK ignition of main burners and heating controls,

move thermostat set point above room temperature and verify

that the burners light and evaporator fan is energized. After en-

suring that the unit continues to heat the building, lower the

thermostat setting below room temperature and verify that the

burners and evaporator fan turn off. (Fan will turn off only if

fan selector switch is in the AUTO. position and after a

45-second delay has elapsed.)

Refer to Table 30 for the correct orifice to use at high

altitudes.

Table 30 — Altitude Compensation*

*As the height above sea level increases, there is less oxygen per

cubic foot of air. Therefore, heat input rate should be reduced at

higher altitudes.

†Orifices available through your Carrier distributor.

ELEVATION

(ft)

74,000 AND 115,000

BTUH NOMINAL

INPUT

150,000 BTUH

NOMINAL INPUT

Natural

Gas

Orifice

Size†

Liquid

Propane

Orifice

Size†

Natural

Gas

Orifice

Size†

Liquid

Propane

Orifice

Size†

0-2,000

33 43 30 38

2,000

34 43 30 39

3,000

35 44 31 40

4,000

36 44 32 41

5,000

36 44 33 42

6,000

37 45 34 43

7,000

37 45 35 43

8,000

38 46 36 44

9,000

39 47 37 44

10,000

41 48 38 45

11,000

43 48 39 45

12,000

44 49 40 46

13,000

44 49 41 47

14,000

45 50 42 47

Fig. 43 — Service Panel Location