9

The smoke detector contains a photoelectric detector approved

for an extended air speed range of 100 to 4000 feet per minute

and an operational temperature range of -4_ to 158_F. Do not

operate the smoke detector out of these ranges.

The smoke detector operates on 24 vac, 120 vac, or

220/240 vac. The thermostat power terminals on the unit are used

to power the smoke detector.

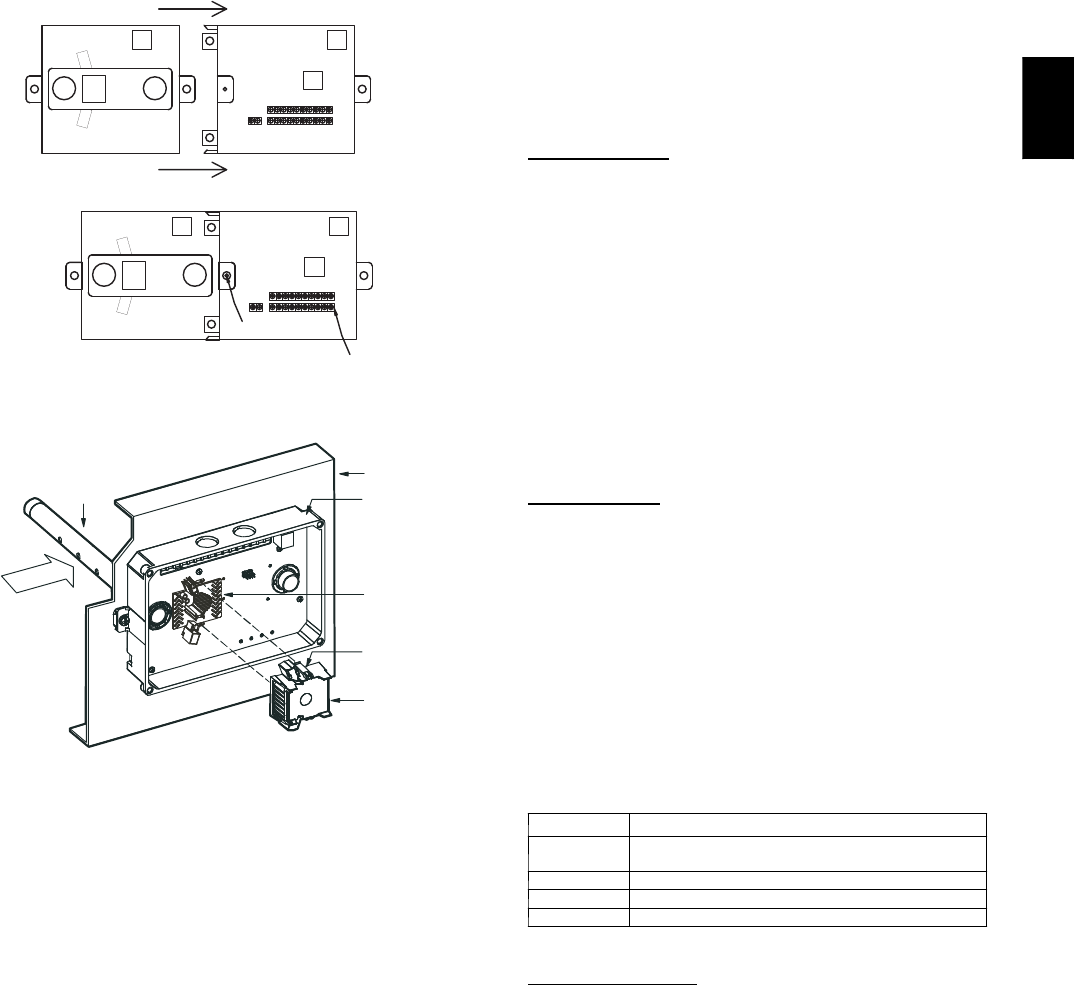

The cover of the controller contains the Alarm, Trouble, Dirty

and Power LEDs. The cover of the sensor contains the Alarm,

Trouble and Power LEDs. (See Fig 2.)

The smoke detector can be reset by a momentary power

interruption, by the reset button on the front cover, by the control

pane l, or by the remote reset accessory.

RETURN SENSOR

CONTROL MODULE

SECURE FROM BEHIND

WITH SCREW

J1

S

E

J1

J2

S

E

RETURN SENSOR

J1

J2

CONTROL MODULE

J1

TERMINAL STRIP

C07182

Fig. 11 --- Sensor Installation

Airflow

HVAC duct

Sampling

tube

Retainer

clip

Optic

plate

Optic

housing

Sensor

housing

C07183

Fig. 12 --- Sensor Cleaning Diagram

MAINTENANCE

IMPORTANT: Notify the pr oper a uthorities that the smoke

detector system is undergoing maintenance, and that the system

will temporarily be out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

Cleaning Procedure

1. Disconnect power from the duct detector then remove the

sensor’s cover.

2. Using a vacuum cleaner, clean compressed air , or a soft

bristle brush, remove loose dirt and debris from inside the

sensor housing and cover. (See Fig 12.)

Use isopropyl alcohol and a lint-free cloth to remove di rt

and other contaminants from the gasket on the sensor’s

cover.

3. Squeeze the retainer clips on both sides of the optic hous-

ing then lift the housing away from the printed circuit

board.

4. Gently remove dirt and debris from around the optic plate

and inside the optic housing.

5. Replace the optic housing and sensor cover.

6. Connect power to the duct detector then perform a sensor

alarm test.

Recommended Service Schedule

S

V isually inspect each sensor connected to the controller

upon installation and once every 6 months thereafter.

S Perform a sensor alarm test on each sensor connected

to the controller upon installation and once every

12 months thereafter.

S Perform a sensor dirty test upon installation and once

every 6 months thereafter or more frequently, as

conditions warrant.

Sensor Tests

Sensor Alarm Test

The sensor alarm test checks a sensor’s ability to signal an alarm

state. This test requires the use of a SD-MAG test magnet.

IMPORTANT: This test places the duct detector into the alarm

state. Unless part of the test, di sconnect all auxiliary equipment

from the controller before performing the test. If duct detector is

connected to a fire alarm system, notify the proper authorities

before performing the test.

To perform a sensor alarm test:

1. Hold the test magnet where indicated on the side of the

sensor housing for seven seconds. Verify that the sensor’s

Alarm LED turns on.

2. Reset the sensor by holding the test magnet against the

sensor housing for two seconds. Verify that the sensor’s

Alarm LED turns off.

Sensor Dirty T

est

The sensor dirty test provides an indication of the sensor’s ability

to compensate for gradual environmental changes. A sensor that

can no longer compensate for environmental changes is

considered 100% dirty and requires cleaning or replacing. This

test requires the use of a SD-MAG test magnet.

To perform a sensor dirty test, hold the test magnet where

indicated on the side of the sensor housing for seven seconds.

Verify that the s ensor’s Dirty LED flashes.

IMPORTANT: Holding the test magnet against the sensor

housing for longer than 7 seconds will put the duct detector into

the alarm state and activate all automatic alarm responses.

The sensor’ s Dirty LED indi cates the results of the dirty test as

shown below.

FLASHES DESCRIPTION

1

0 to 25% dirty.This is typical on a newlyinstalled duct

detector.

2 26to 50% dirty

3 51to 75% dirty

4 76to 99% dirty

Controller Tests

Controller Alarm Test

The controller alarm test checks the controller’s ability to initiate

and indicate an alarm state

.

IMPORTANT: This test places the duct detector into the alarm

state. Unless part of the test, di sconnect all auxiliary equipment

from the controller before performing the test. If duct detector is

connected to a fire alarm system, notify the proper authorities

before performing the test.

CRSMK