42VMC

GB - 8

Refrigerant connections

Connection to the unit

Insufficient tightening torque will cause gas leaks.

Overtightening the fittings will damage the tube flaring and cause

gas leaks.

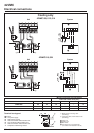

Tubing diameter Torque

mm (inches) Nm

6.35 (1/4”)18

9.52 (3/8”)42

12.70 (1/2”)55

Once all connections have been completed, check for leaks by

applying soapy water to them.

If incorrect connection or removal of the unit results in a refrigerant

gas leak, check the refrigerant charge as indicated in the

“OUTDOOR UNIT INSTALLATION MANUAL”.

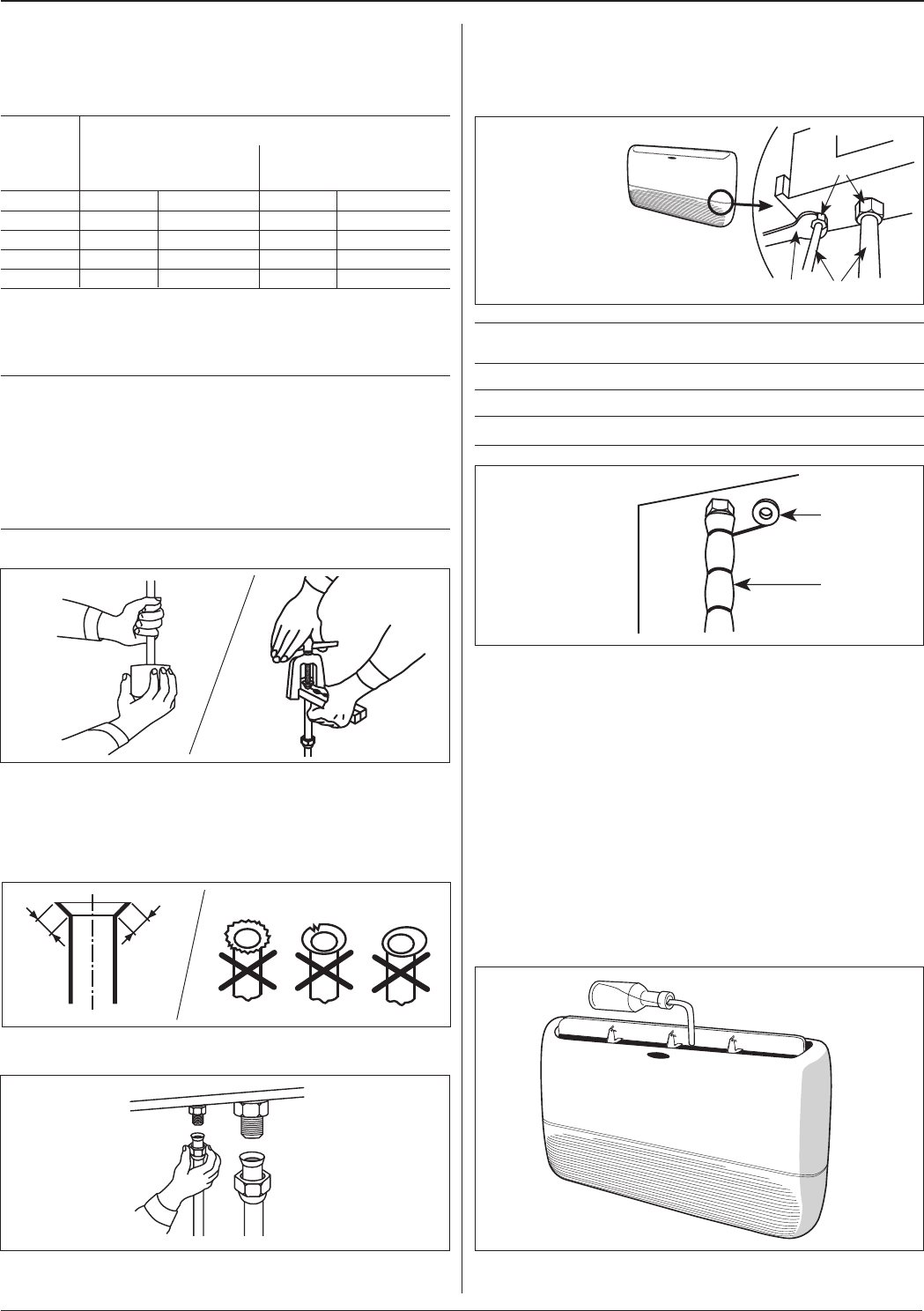

Finally wrap connections with anti-condensate insulation and

tighten with tape, without exerting great pressure on the insulation.

Repair and cover any possible cracks in the insulation.

Connection pipes and electric cables between indoor and outdoor

units must be fixed to the wall with appropriate conduits.

Check

Pour water into the condensate drain pan and check that it flows

freely to the drain.

Make refrigerant connections before connecting the system to

the power supply.

Refer to the outdoor unit installation manual for tube sizing,

and limitations (slopes, length, number of curves allowed,

refrigerant charge, etc.)

Tubing diameter

Gas Liquid

Model (Suction) (Discharge)

mm (inches) mm (inches)

009 9.52 (3/8”)6.35(1/4”)

012 12.70 (1/2”)6.35 (1/4”)

014 12.70 (1/2”)6.35 (1/4”)

018 12.70 (1/2”)6.35 (1/4”)

024 12.70 (1/2”)6.35(1/4”)

• For refrigerant tubes use seamless, insulated refrigeration grade

tube, (Cu DHP type according to ISO 1337), degreased and

deoxidized, suitable for operating pressures of at least 4200 kPa.

Under no circumstances use sanitary type copper pipe.

Note:

• Do not kink or flatten the tubes.

• Avoid bends with a bending radius of less than 100 mm.

• Do not bend copper tubes more than three times at the same point.

• Do not remove flare fittings from unit tubes before actually making

the connections.

• Do not fasten the insulation too tightly to the tubes with straps or

tape.

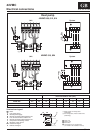

Flaring the end of the tubing

Remove protective caps from the copper tube ends. Position tube

end downward, cut the tube to the required length and remove the

burrs with a reamer.

Remove flare nuts from the unit connections and place them on the

tube end.

Flare the tube with a flaring tool.

Flare end must not have any burrs or imperfections.

The length of the flared walls must be uniform.

Finger-tighten the fitting several turns, then tighten it fully with two

wrenches by applying the tightening torque indicated in the table.

ቢ Adijustable wrench or

torque wrench

ባ Connecting pipes

ቤ Unit connections

ብ Tube insulation

ቦ Fastening tape

L

L

ቦ

ብ

ቢባ

ቤ