31

6. If solution is too weak, add more antifreeze until desired

strength is reached, then circulate solution through coil

for 15 minutes or until concentration is satisfactory.

7. Remove upper line from reservoir to reversible pump.

Drain coil to reservoir and then close service valve.

8. Break union and remove reservoir and its lines.

9. Leave coil flanges or coupling open and auxiliary drain

valves open until spring.

AIR DRYING METHOD OF COIL PROTECTION (Unit

and coil must be level for this method.)

1. Close coil water supply and return main valves.

2. Drain coil as described in procedures for Antifreeze

Methods of Coil Protection.

3. Connect air supply or air blower to inlet header connec-

tion and close its drain connection.

4. Circulate air and check for air dryness by holding mirror

in front of open vent in outlet header drain connection.

Mirror will fog if water is still present.

5. Allow coil to stand for a few minutes; repeat step 4 until

coil is dry.

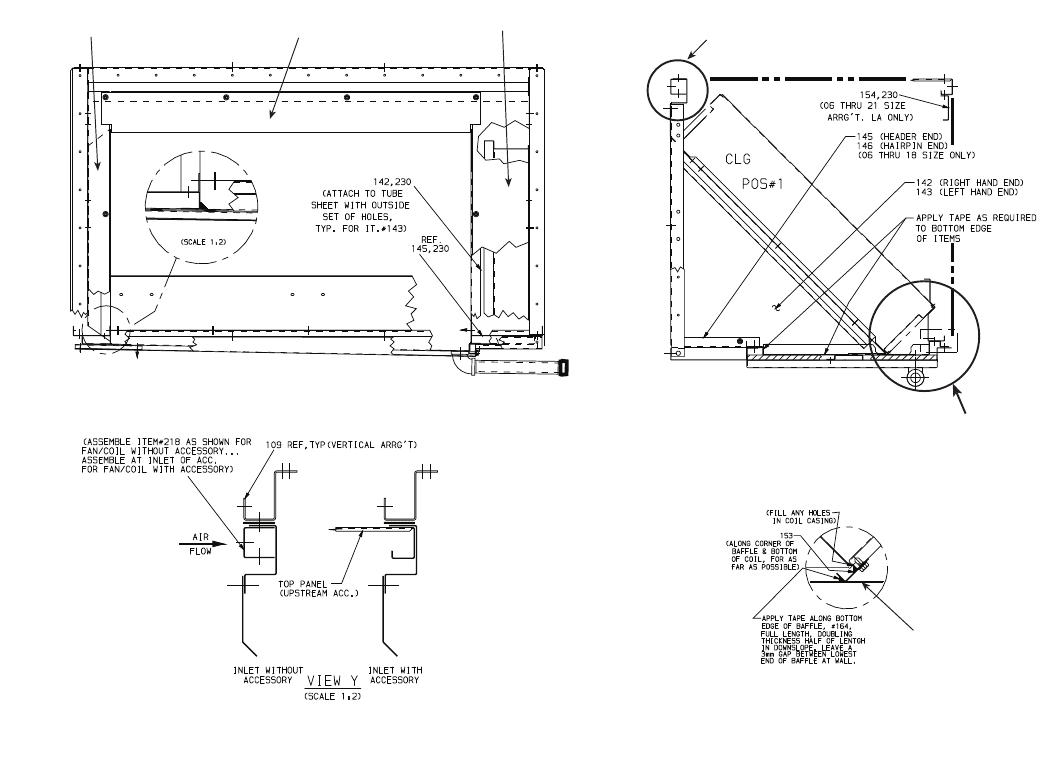

Field-Installed Coils (39LA,LD Only)

When a 39LA or 39LD unit is ordered without the coil, the fol-

lowing loose parts are shipped: (see Fig. 37)

• bottom coil baffle

• side hairpin baffle

• side header baffle

• top coil baffle

These parts should be field-installed onto the coil before

placing the coil into the unit. Once the baffles are installed,

install the coil with the downstream bottom of the coil attached

to the upright mounting flange as shown in Fig. 36. Adjust

the coil and then attach the top coil baffle to the top flange

provided.

Coil Removal

HORIZONTAL UNIT SLANT COIL REMOVAL (39LA

Units)

NOTE: Item numbers are in Fig. 38.

1. Refer to Fig. 4 for service area clearance.

2. Disconnect piping (Item 5).

3. On top panel (Item 3), remove screws located directly

above side panels (Items 2 and 6). Top panels may be re-

moved from unit to provide more workspace, but it is not

required.

4. Remove right side panels (Item 6).

5. If accessory is present, remove accessory side panel

(Item 1) on left side of unit. Detach filter track support

bracket if upstream accessory is a filter.

6. Remove screws from inside baffle (Item 13). Leave baffle

attached to left side panel (Item 2).

7. Remove left side panel (Item 2).

8. Remove condensate baffle (Item 8).

9. Remove coil holddown screws (Items 9 and 11).

10. Remove baffle screws (Item 4) from downstream side of

coil.

11. Tilt coil (Item 10) away from coil support panels (Items 7

and 12) and slowly slide coil out of unit.

12. Replace coil by reversing preceding Steps 1-11.

BOTTOM COIL

BAFFLE

SEE TOP

FLANGE DETAIL

BOTTOM

MOUNTING

FLANGE

TOP FLANGE DETAIL

TOP COIL

BAFFLE

SIDE HEADER

BAFLE

SIDE HAIRPIN

BAFFLE

Fig. 37 — Field-Installed Coils (39LA and LD only)