NOTE: In some cases noise in the living area has been traced to

gas pulsations from improper installation of equipment.

INSTALLATION RECOMMENDATIONS

1. Locate unit away from windows, or areas where unit operating

sounds may disturb customer.

2. Ensure that vapor and liquid tube diameters are appropriate to

capacity of unit. (See Table 1.)

3. Run refrigerant tubes as directly as possible by avoiding

unnecessary turns and bends.

4. Leave some slack between structure and unit to absorb

vibration.

5. When passing refrigerant tubes through wall, seal opening

with RTV or other pliable silicon-based caulk. (See Fig. 9.)

6. Avoid direct lineset contact with water pipes, ductwork, floor

joists, wall studs, floors, and walls.

7. Do not suspend refrigerant tubing from joists and studs with a

rigid wire or strap which comes in direct contact with tubing.

(See Fig. 9.)

8. Ensure that tubing insulation is pliable and it completely

surrounds vapor tube.

9. When necessary, use hanger straps which are 1 in. wide and

conform to shape of tubing insulation. (See Fig. 9.)

10. Isolate hanger straps from insulation by using metal sleeves

bent to conform to shape of insulation.

If refrigerant tubes or indoor coil is exposed to atmospheric

conditions for longer than 5 minutes, it must be evacuated to 500

microns to eliminate contamination and moisture in the system.

OUTDOOR UNITS CONNECTED TO FACTORY-APPROVED

INDOOR UNITS — Outdoor unit contains correct system refrig-

erant charge for operation with indoor approved unit when

connected by 15 ft of field-supplied or factory accessory tubing.

Check refrigerant charge for maximum efficiency. (See Step

10—Checking Charge.)

REFRIGERANT TUBING — Connect tubing to fittings on out-

door unit vapor- and liquid-service valves. (See Fig. 2.)

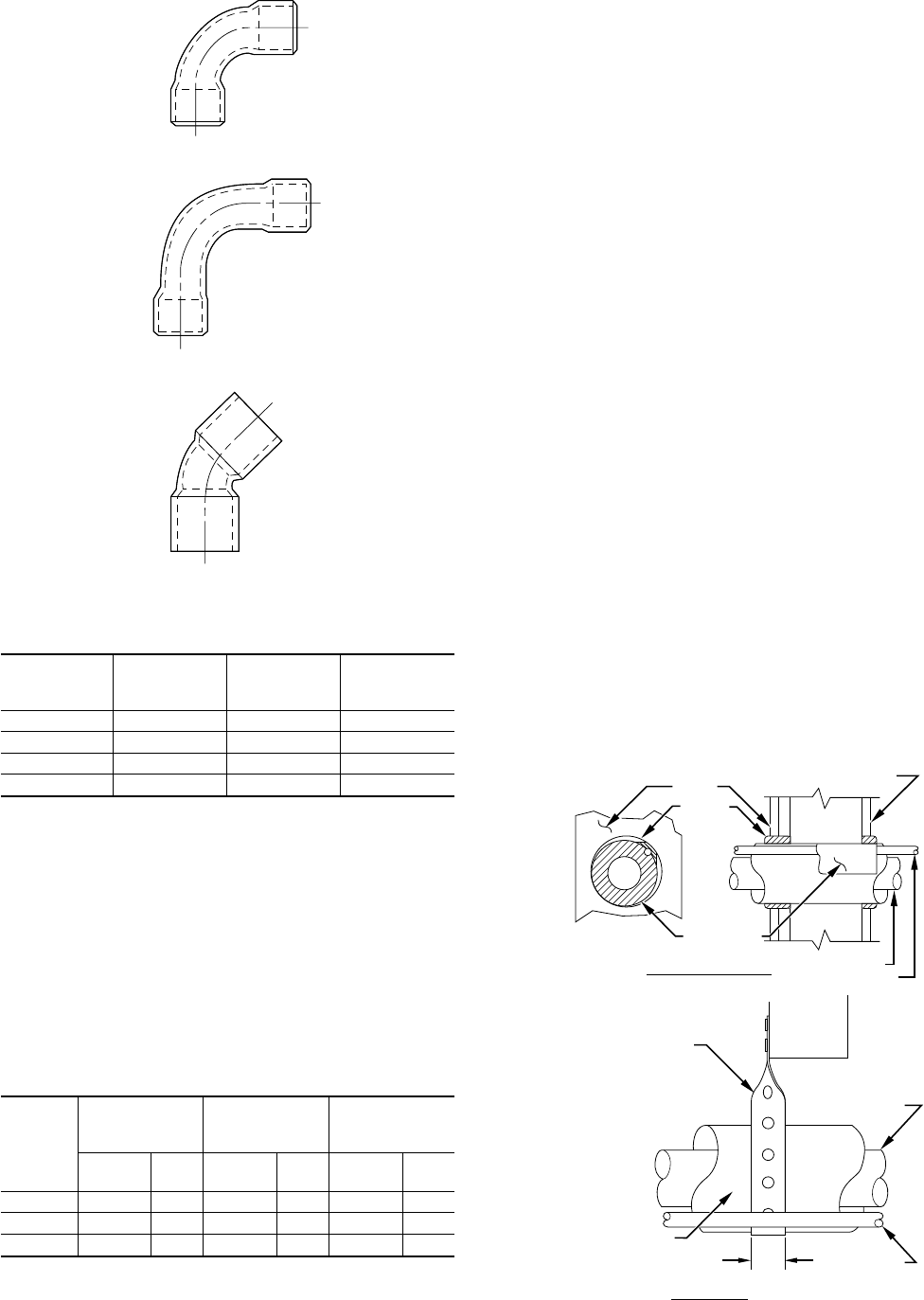

Fig. 8—Tube Bend Losses for Long Lines

Fitting Losses in Equivalent Ft

TUBE

SIZE

OD (IN.)

90˚ STD

FIG. 8-A

90˚ L.R.

FIG. 8-B

45˚ STD

FIG. 8-C

5/8 1.6 1.0 0.8

3/4 1.8 1.2 0.9

7/8 2.0 1.4 1.0

1-1/8 2.6 1.7 1.3

A92498

90° LONG RAD

B

90° STD

A

45° STD

C

→ Table 1—Refrigerant Connections and

Recommended Liquid- and Vapor-Tube Diameters

UNIT

SIZE

LIQUID (IN.) VAPOR (IN.)

VAPOR

(LONG LINE)

(IN.)

Connect

Dia

Tube

Dia

Connect

Dia

Tube

Dia

Connect

Dia

Tube

Dia

024 3/8 3/8 5/8 5/8 5/8 3/4

030, 036 3/8 3/8 3/4 3/4 3/4 7/8

042, 048 3/8 3/8 7/8 7/8 7/8 7/8

Note: Tube diameters are for lengths up to 50 ft. For tubing lengths greater

than 50 ft, consult Long-Line Application Guideline.

Fig. 9—Piping Installation

A92469

OUTDOOR

WALL

CAULK

INDOOR WALL

NOTE:

AVOID CONTACT BETWEEN TUBING AND STRUCTURE

VAPOR TUBE

LIQUID TUBE

LIQUID TUBE

THROUGH THE WALL

JOIST

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

VAPOR TUBE

INSULATION

INSULATION

1

″

MIN

SUSPENSION

4