4. After wrapping service valve with a wet cloth, tubing set can

be brazed to service valve using either silver bearing or

non-silver bearing brazing material.

5. Refrigerant tubing and indoor coil are now read for leak

testing. This check should include all field and factory joints.

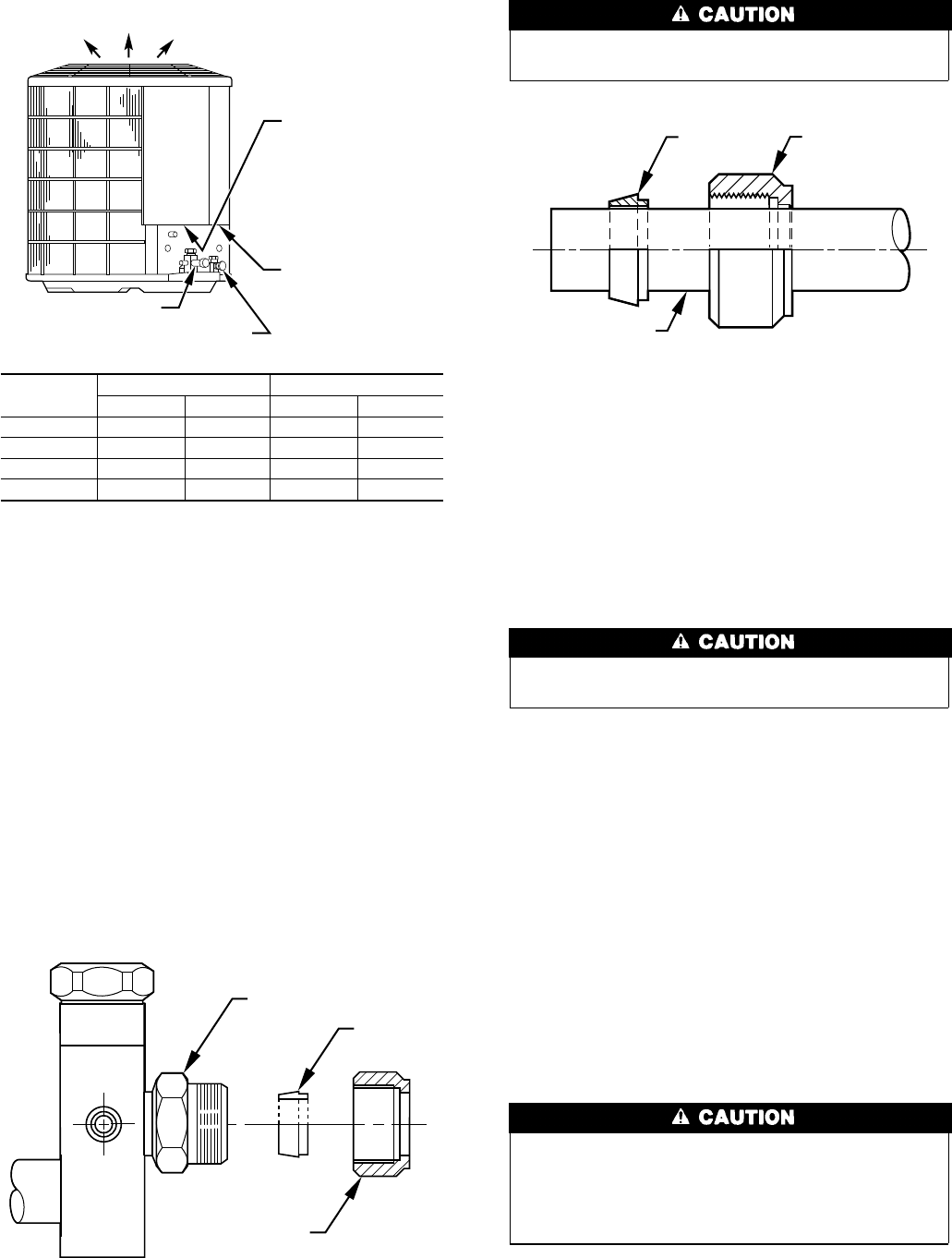

MECHANICAL CONNECTION (38CKQ MODELS)

1. Cut tubing to correct length, deburr, and size as necessary,

making sure tube ends are square. If a large burr is evident, ID

and OD must be deburred to allow tube to bottom in valve.

2. Remove lock nuts and ferrules from plastic bags taped to

service panel. (See Fig. 5.)

If undersized, damaged, or elliptically shaped tubing is used

when making connection, leaks could result.

3. Slide lock nut and ferrule onto each tube. (See Fig. 6.)

4. Apply a few drops of refrigerant oil to ferrule and valve

threads to reduce assembly torque and assist sealing.

5. Insert tube end into service valve until it bottoms.

6. Push ferrule into place and hand tighten nut until an increase

in torque is felt.

7. Mark nut and tube and tighten 1-1/2 turns from mark. (See

Fig. 7.) Keep tube bottomed in valve while tightening nut.

NOTE: A backup wrench on the hex part of the suction valve is

required while tightening.

The tube end must stay bottomed in the service valve during

final assembly to ensure proper seating, sealing, and rigidity.

MECHANICAL FITTING REPAIR

To replace damaged ferrule or tubing proceed as follows.

1. Attach gages to service valves.

2. Close liquid service valve and operate unit to pump refrigerant

charge into condenser coil.

3. When suction pressure reaches 5 psig, shut unit off. Do not

operate unit in a vacuum.

4. Close suction service valve and recover refrigerant in tubing.

5. Back-off locknut and ferrule onto tube.

6. Remove damaged part of tubing using tubing cutter. Repeat

installation procedure previously outlined using new ferrule.

7. Evacuate tubing set and indoor coil. Check for leaks.

8. Open service valves or recharge unit. Check refrigerant

charge.

Step 7—Install Solenoid Valve In Liquid Tube (If Re-

quired)

Not all applications require use of a liquid tube solenoid

valve. If your unit has been shipped with a liquid tube

solenoid valve in the unit, it must be installed for performance

enhancement. The liquid tube solenoid valve must be ener-

gized during evacuation for complete removal of refrigerant.

Before making liquid tube connections, install factory-supplied

solenoid valve on indoor liquid fitting. (See Fig. 8.) Be sure to use

flare adapter supplied with the indoor coil when making connec-

tions.

Fig. 4—Refrigerant Tube Dimensions/Connections

UNIT SIZE

LIQUID TUBE VAPOR TUBE

Conn Dia Tube Dia Conn Dia Tube Dia

018, 024 3/8 3/8 5/8 5/8

030, 036 3/8 3/8 3/4 3/4

042, 048 3/8 3/8 7/8 7/8

060 3/8 3/8 7/8 1-1/8

NOTE: Tube diameters are for lengths up to 50 ft. For tubing lengths greater

than 50 ft, consult your local distributor.

If refrigerant tubing or indoor coil is exposed to atmosphere, it

must be evacuated to a minimum of 500 microns to eliminate

contamination and moisture in the system.

A97009

LIQUID LINE CONN

FIELD CONTROL

SUPPLY CONN

7

⁄

8

″ DIA HOLE

FIELD POWER

SUPPLY CONN

7

⁄

8

″ DIA HOLE WITH

1

1

⁄

8

″ DIA KNOCKOUT

AND

1

3

⁄

8

″ DIA

KNOCKOUT

AIR DISCHARGE

SUCTION LINE CONN

Fig. 5—Mechanical Fitting Assembly (38CKQ)

A92120

VALVE FITTING

FERRULE

LOCK NUT

Fig. 6—Lock Nut/Ferrule Positioning (38CKQ)

A92121

FERRULE LOCK NUT

TUBING

3