Step 3—Clearance Requirements

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Common clearances are 6

in. on 1 side, 12 in. on 2 sides, and 30 in. on service side of unit.

Allow 24 in. between units. Discharge air must be unobstructed

and must not recirculate.

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

On rooftop applications, locate unit at least 6 in. above roof

surface. Place unit above a load-bearing wall and isolate unit and

tubing set from structure.

Arrange supporting members to adequately support unit and

minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Step 4—Operating Ambients

The minimum outdoor operating ambient in cooling mode is 55°F,

and the maximum outdoor operating ambient in cooling mode is

125°F.

Step 5—Metering Device

If unit is being installed with piston, check indoor coil piston to see

if it matches the required piston shown on outdoor unit rating plate.

If it does not match, replace indoor coil piston with piston shipped

with outdoor unit. The piston shipped with outdoor unit is correct

for any approved indoor coil combination.

Step 6—Make Tubing Connections

Relieve pressure and recover all refrigerant before system

repair or final unit disposal to avoid personal injury or death.

Use all service ports and open all flow-control devices,

including solenoid valves.

To prevent compressor damage DO NOT bury more than 36

in. of refrigerant tubing. If ANY tubing is buried, provide 6

in. vertical rise at service valve.

To prevent damage to unit or service valves observe the

following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Connect outdoor unit to indoor sections using accessory tubing

package or field-supplied tubing of refrigerant grade, correct size,

and condition. Refer to Fig. 4 for refrigerant tube dimensions and

connections. For tubing requirements beyond 50 ft, consult your

local distributor or the Long-Line Application Guideline.

SWEAT CONNECTION

1. Consult local code requirements.

2. Connect tubing to fittings on outdoor unit vapor and liquid

service valves.

3. Service valves are closed from factory and ready for brazing.

Fig. 2—Connecting Tubing Installation

A94028

INSULATION

VAPOR TUBE

LIQUID TUBE

OUTDOOR WALL INDOOR WALL

LIQUID TUBE

VAPOR TUBE

INSULATION

CAULK

Avoid contact between tubing and structureNOTE:

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

JOIST

1″ MIN.

SUSPENSION

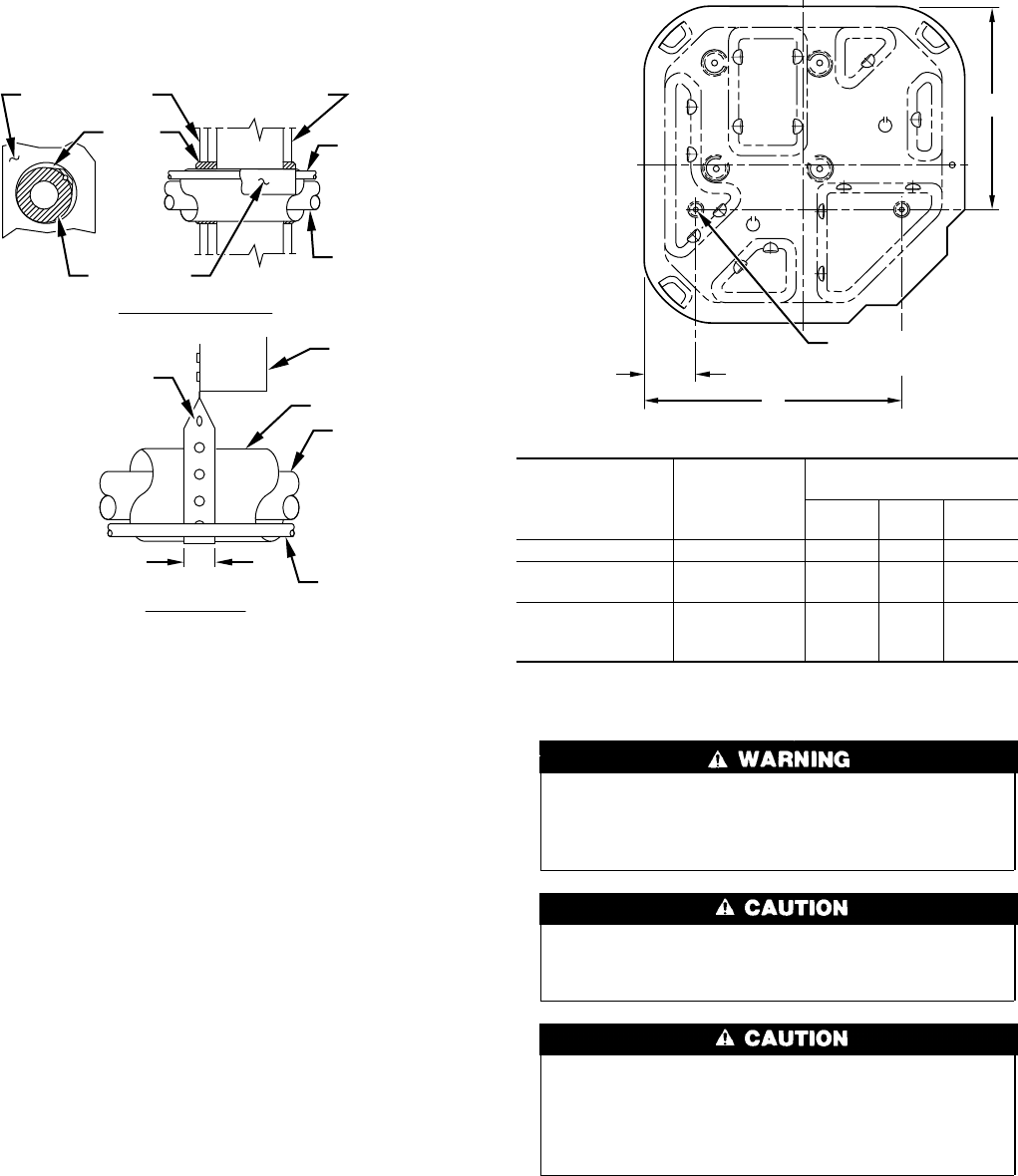

Fig. 3—Mount Unit to Pad

A94199

UNIT SIZE

MIN PAD

DIM (IN.)

TIEDOWN KNOCKOUT

LOCATIONS

A

(In.)

B

(In.)

C

(In.)

38CKC(Q)018, 024 18 X 18 3 15 10-3/16

38CKC(Q)030-042

38CMC018-030

22-1/2 X 22-1/2 3-11/16 18-1/8 14-3/8

38BRC024-060

38CKC(Q)048, 060

38CMC036-060

30 X 30 6-1/2 23-1/2 20

C

B

A

3

⁄

8

″D. (9.53) TIEDOWN

KNOCKOUTS (2) PLACES

2