2

50XP

cooling unit that is pre-wired, pre-

piped, and pre-charged for minimum

installation expense. 50XP units are

available in a variety of standard

cooling sizes with voltage options to

meet residential and light commercial

requirements. Units are light weight,

and install easily on a rooftop or at

ground-level. The hightech, composite

base pan eliminates rust problems

associated with ground level

applications.

Durable, dependable

components

Scroll Compressors

are designed for

high efficiency. Each compressor is

hermetically sealed against

contamination to help promote longer

life and dependable operation.

Vibration isolation provides quiet

operation. Compressors have internal

high-pressure and overcurrent

protection.

Convertible duct configuration

Unit is designed for easy use in either

downflow or horizontal applications.

Each unit is easily converted from

horizontal to downflow.

Direct-drive variable speed blower

motor

is standard on all 50XP models.

Direct-drive, PSC condenser-fan

motors

are designed to help reduce

energy consumption and provide for

cooling operation down to 55°F outdoor

temperature. Motormaster® II low

ambient kit is available as a field-

installed accessory.

Corporate thermostats

include the

Time Guard® II anti-short cycle

protection circuitry. If a non-Corporate

thermostat without anti-short cycle

protection, is used the Time Guard II

field installed anti-short cycle kit is

recommended.

Refrigerant system

is designed to

provide dependability. Liquid refrigerant

filter driers are used to promote clean,

unrestricted operation. Each unit leaves

the factory with a full Puron® refrigerant

charge. Refrigerant service connections

are standard on the suction and discharge

lines for checking operating pressures.

Thermostatic Expansion Valve

– A

hard shutoff, balance port TXV

maintains a constant superheat at the

evaporator exit (cooling cycle) resulting

in higher overall system efficiency.

Evaporator and condenser coils

are

computer-designed for optimum heat

transfer and cooling efficiency. The

evaporator coil is fabricated from

copper tube and aluminum fins and is

located inside the unit for protection

against damage. The condenser coil is

internally mounted on the top tier of the

unit. Copper fin coils and pre-coated fin

coils are available from the factory by

special order. These coils are

recommended in applications where

aluminum fins are likely to be damaged

due to corrosion. They are ideal for

seacoast applications.

High and Low Pressure Switches

give

added safety and reliability to the

compressor.

Low sound ratings

ensure a quiet

indoor and outdoor environment with

sound ratings as low as 72 dB.

(See page 3.)

Easy to service cabinets

provide easy

single-panel accessibility to serviceable

components during maintenance and

installation. The basepan with

integrated drain pan provides easy

ground level installation with or without

a mounting pad. Convenient handholds

are provided to manipulate the unit on

the jobsite. A nesting feature ensures a

positive basepan to roof curb seal when

the unit is roof mounted. A convenient

3/4-in. wide perimeter flange makes

frame mounting on a rooftop easy.

Louvered Grille

provides hail and

vandalism protection for the coil.

Downflow operation

is easily provided

in the field to allow vertical ductwork

connections. The basepan utilizes

knockout style seals on the bottom

openings to ensure a positive seal in the

horizontal airflow mode.

Cabinets

are constructed of heavy-

duty, phosphated, zinc-coated

prepainted steel capable of

withstanding 500 hours of salt spray.

Interior surfaces of the evaporator and

electric heater compartments are

insulated with cleanable semi-rigid

insulation board, which keeps the

conditioned air from being affected by

the outdoor ambient temperature and

provides improved indoor air quality.

(Conforms to American Society of

Heating, Refrigeration and Air

Conditioning Engineers No. 62P.) The

sloped drain pan minimizes standing

water in the drain, which is provided

with an external drain.

Standard metal duct covers

with

insulation come with the unit and cover

the horizontal duct openings. These can

be left in place if the unit is converted to

downflow.

Table of contents

Page

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

Model Number Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

ARI Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5,6

Base Unit Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7,8

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

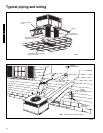

Typical Piping and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Application Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18, 19

Typical Wiring Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20, 21

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23, 24