Step 5 — Make Electrical Connections

Unit cabinet must have uninterrupted, unbroken elec-

trical ground to minimize the possibility of personal

injury if an electrical fault should occur. This ground

may consist of electrical wire connected to unit ground

lug in control compartment, or conduit approved for elec-

trical ground when installed in accordance with U.S.A.

National Electrical Code (Ref: ANSI/NFPA 70-1987)

or equivalent local electrical codes. Failure to follow this

warning could result in the installer being liable for per-

sonal injury of others.

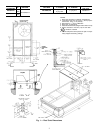

FIELD POWER SUPPLY — Pigtails are provided for field

wire connections. Use factory-supplied splices or copper/

aluminum connector.

When installing units, provide a disconnect per local codes.

All field wiring must comply with local requirements.

Install conduit through side panel openings. For units with-

out electric heat, install conduit between disconnect and con-

trol box. Install power lines to terminal connections as shown

in Fig. 6. For units with electric resistance heat, refer to Table

2 to determine appropriate power wiring figure (Fig.7-13)

and route lines as indicated in appropriate figure.

Voltage to compressor terminals during operation must be

within voltage range indicated on unit nameplate (also see

Table 2). On 3-phase units, voltages between phases must be

balanced within 2% and the current within 10%. Use the for-

mula shown in Table 2, Note 3 to determine the % voltage

imbalance. Operation on improper line voltage or excessive

phase imbalance constitutes abuse and may cause damage to

electrical components. Such operation would invalidate any

applicable Carrier warranty.

When electric heat is installed, remove knockouts for ap-

propriate size conduit from unit block-off panel and single

point box. Install conduit (rigid or electro-metallic tubing)

through conduit drip boot as shown in Fig. 14. Drip boot

eliminates the need for water tight conduit fittings at the single

point box. Refer to Fig. 15 for component locations.

Fig. 7 — Electric Heater Power Wiring Connections — 50LJQ, 220-3-50 and 400-3-50;

Single Point Kit 50DJ902021 and 50DJ902071

LEGEND

C—Contactor

IFC — Indoor-Fan Contactor

TB — Terminal Block

Field Wiring

Factory Wiring

Splice Connection (Factory Supplied)

Fig. 6 — Power Wiring Connections

LEGEND FOR FIG. 7-13

EQUIP — Equipment

FU — Fuse

GND — Ground

HTR — Heater

TB — Terminal Block

7