6

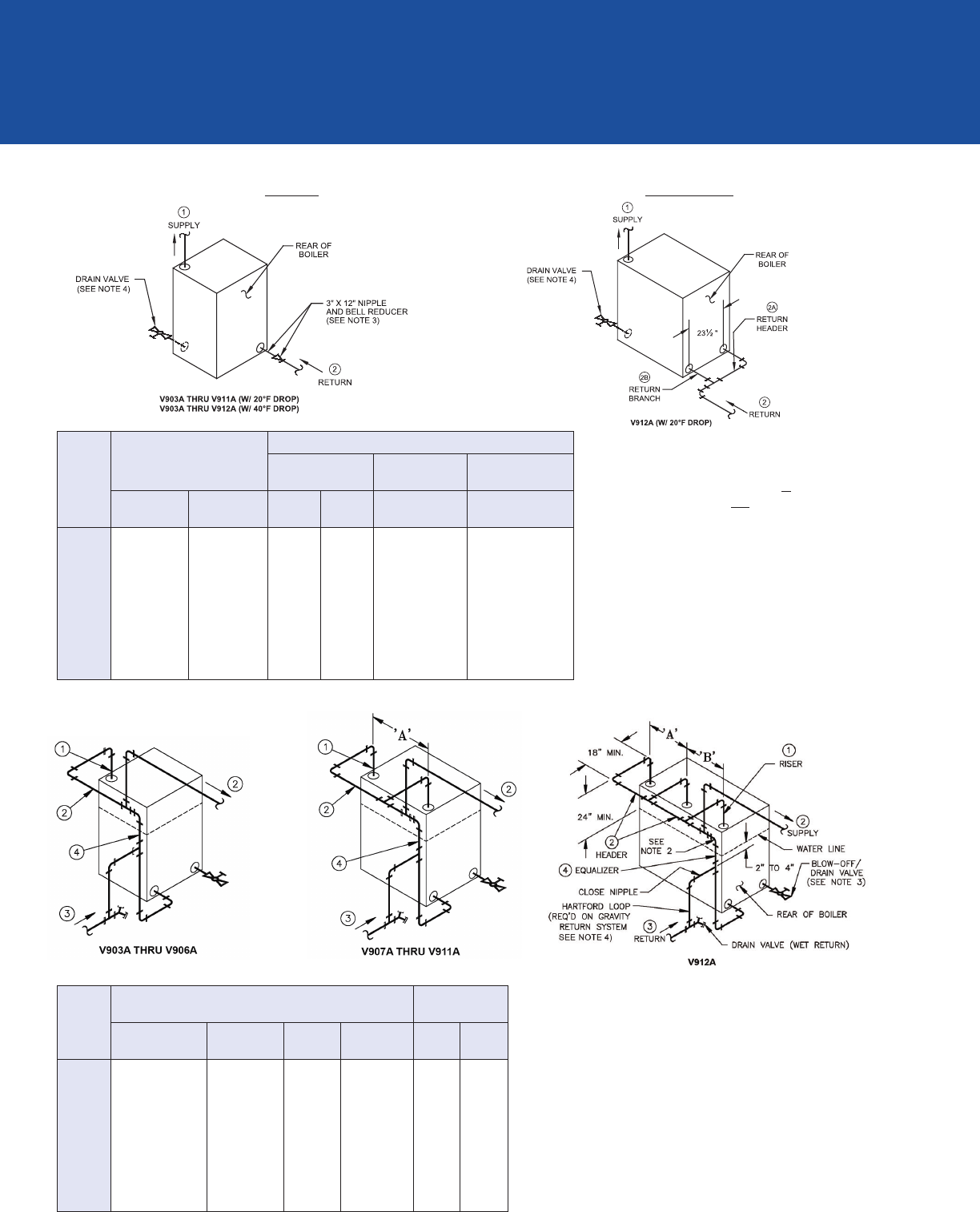

NOTES:

1. Allpipingisschedule40.

2. Pipesizeslistedarebasedona20°For40°Fdifferential

(temperature drop). Select one to match application.

Consult factory if boilers are used in low temperature

applications or blending/mixing devices.

3. Whenspeciedreturnpipingsizeislessthan3”,install

3”X12”nippleandappropriatesizebellreducerdirectly

into boiler return tapping as shown.

4. Drainvalve—ballvalvepreferable,gatevalveacceptable

alternative (supplied by others).

-MinimumvalvesizeperASMEcodeis3/4”NPT

5. Formultiplewaterboilerpiping,consultfactory.

WATER BOILER PIPING

To be used when system return water is not lessthan135°Fforprolongedperiodsoftimeandsystemowdoes not impact flow through the boiler

MODEL

SUPPLY PIPING SIZE

(IN.) (1)

RETURN PIPING SIZE (IN.)

RETURN (2)

RETURN

HEADER (2A)

RETURN BRANCH

(QTY.) SIZE (2B)

20¡F D ROP 40¡F D ROP

20¡F

DROP

40¡F

DROP 20¡F D ROP

20¡F

DROP

V903A

V904A

V905A

V906A

V907A

V908A

V909A

V910A

V911A

V912A

2

2

2

2-1/2

2-1/2

2-1/2

3

3

3

4

1-1/2

1-1/2

1-1/2

1-1/2

2

2

2

2-1/2

2-1/2

2-1/2

2

2

2

2-1/2

2-1/2

2-1/2

3

3

3

4

1-1/2

1-1/2

1-1/2

1-1/2

2

2

2

2-1/2

2-1/2

2-1/2

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

3

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

(2) 3

STEAM BOILER PIPING

NOTES:

1. Allpipingisschedule40.

2. To prevent condensate from being trapped in header, do not reduce

equalizer elbow at header connection.

3. Drain/blowoffvalve—ballvalvepreferable,gatevalveacceptable

alternative (supplied by others).

–MinimumvalvesizeperASMEcodeis3/4”NPT903A/905A;

1”NPT906A/910A;1-1/4”NPT911A/912A.

Ð Increasing the valve size will improve the blowdown operation.

Ð In all cases, piping connection blowoff valve to boiler should be

full size to the point of discharge.

4. Forpumpedreturnsystems,seeV9Ainstallationmanual.

5. Formultiplesteamboilerpiping,consultfactory.

MODEL

PIPING SIZE (IN INCHES)

RISER SPACING

(INCHES)

RISER

(Qty.) SIZE (1)

HEADER &

SUPPLY (2)

RETURN

(3)

EQUALIZER

(4) 'A' 'B'

V903A

V904A

V905A

V906A

V907A

V908A

V909A

V910A

V911A

V912A

(1) 3

(1) 4

(1) 4

(1) 4

(2) 4

(2) 4

(2) 4

(2) 4

(2) 4

(3) 4

3

4

4

4

6

6

6

6

6

6

1-1/2

2

2

2-1/2

2-1/2

2-1/2

2-1/2

3

3

3

2

2

2

2-1/2

2-1/2

2-1/2

2-1/2

3

3

3

Ñ

Ñ

Ñ

Ñ

36

42

48

54

60

30

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

Ñ

36

V9 Series Piping Recommendations

Water and Steam