25

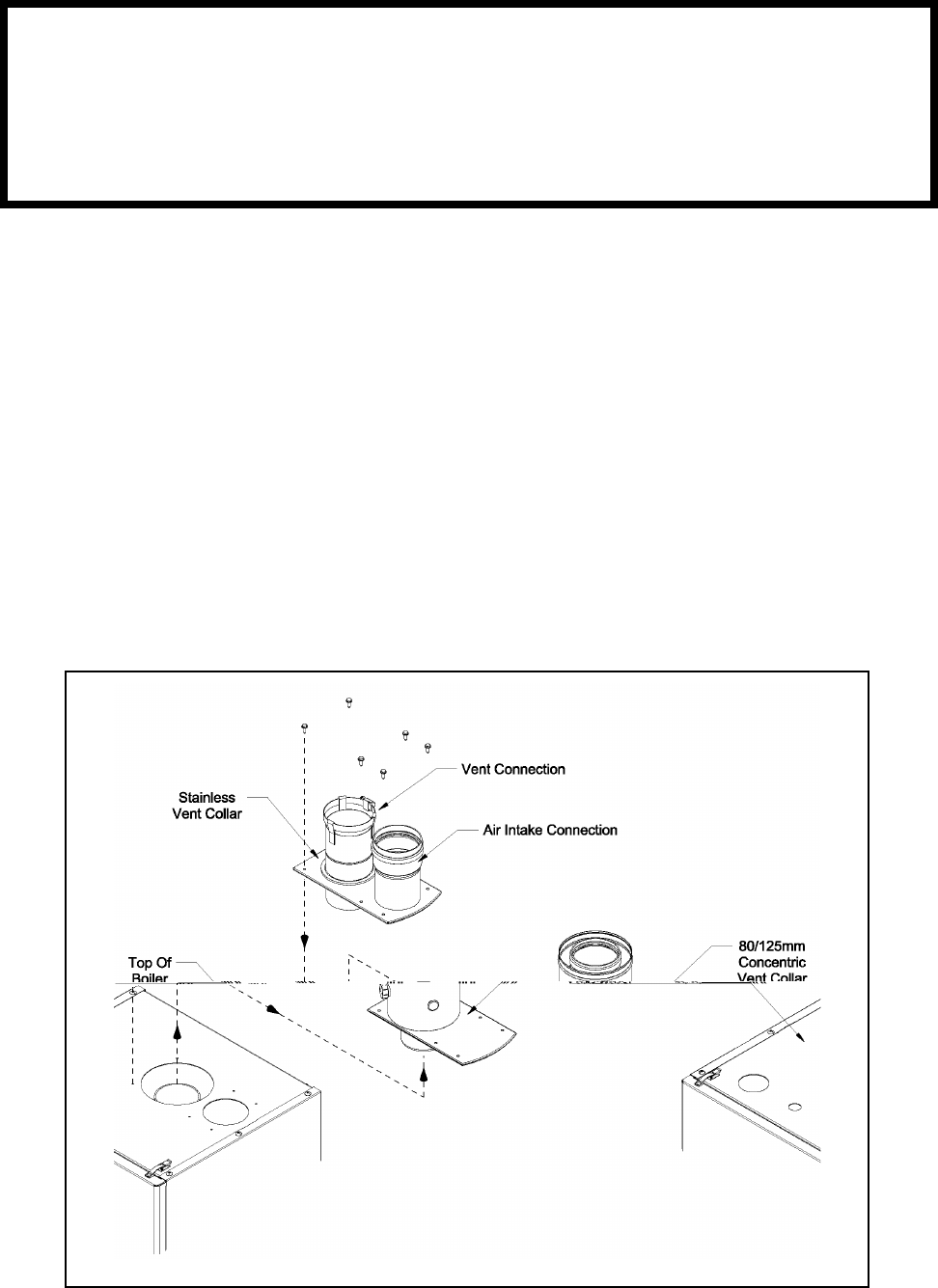

D. Assembly of Stainless Steel Venting

CAUTION

Vent systems made by Heat Fab, Protech, and Z-Flex rely on gaskets for proper sealing. When

these vent systems are used, take the following precautions:

• Make sure that gasket is in position and undamaged in the female end of the pipe.

• Make sure that both the male and female pipes are free of damage prior to assembly.

• Only cut vent pipe as permitted by the vent manufacturer in accordance with their instructions.

When pipe is cut, cut end must be square and carefully de burred prior to assembly.

1) General Assembly Notes:

a) Where the use of “silicone” is called for in the following instructions, use GE RTV 106 for the vent collar. Air

inlet piping sections are sealed with any general-purpose silicone sealant such as GE RTV102. PVC air inlet piping

sections are connected with PVC cement.

b) Longitudinal welded seams should not be placed at the bottom of horizontal sections of exhaust pipe.

c) Do not drill holes in vent pipe.

d) Do not attempt to mix vent components of different vent system manufacturers.

2) Mounting Stainless steel vent collar -The use of stainless steel venting requires the stainless steel vent collar which

replaces the 80/125mm concentric collar supplied with the boiler. To install the stainless steel vent collar:

a) Remove the six #10 sheet metal screws which attach the 80/125mm collar to the boiler.

b) Remove the collar from the boiler (this may be easier if a twisting motion is applied to the collar while removing

it.

c) Lubricate the brown gasket in the female end of the plastic vent stub (inside the boiler) with a few drops of water.

d) Push the stainless steel vent collar onto the boiler with a slight twisting motion. Make sure that the stainless steel

vent adaptor is inserted at least 1” into the boiler stub.

e) Secure the collar fl ange to the top of the boiler with the sheet metal screws removed in Step (a).

Figure 7.16: Installation of Stainless Steel Vent Collar