22

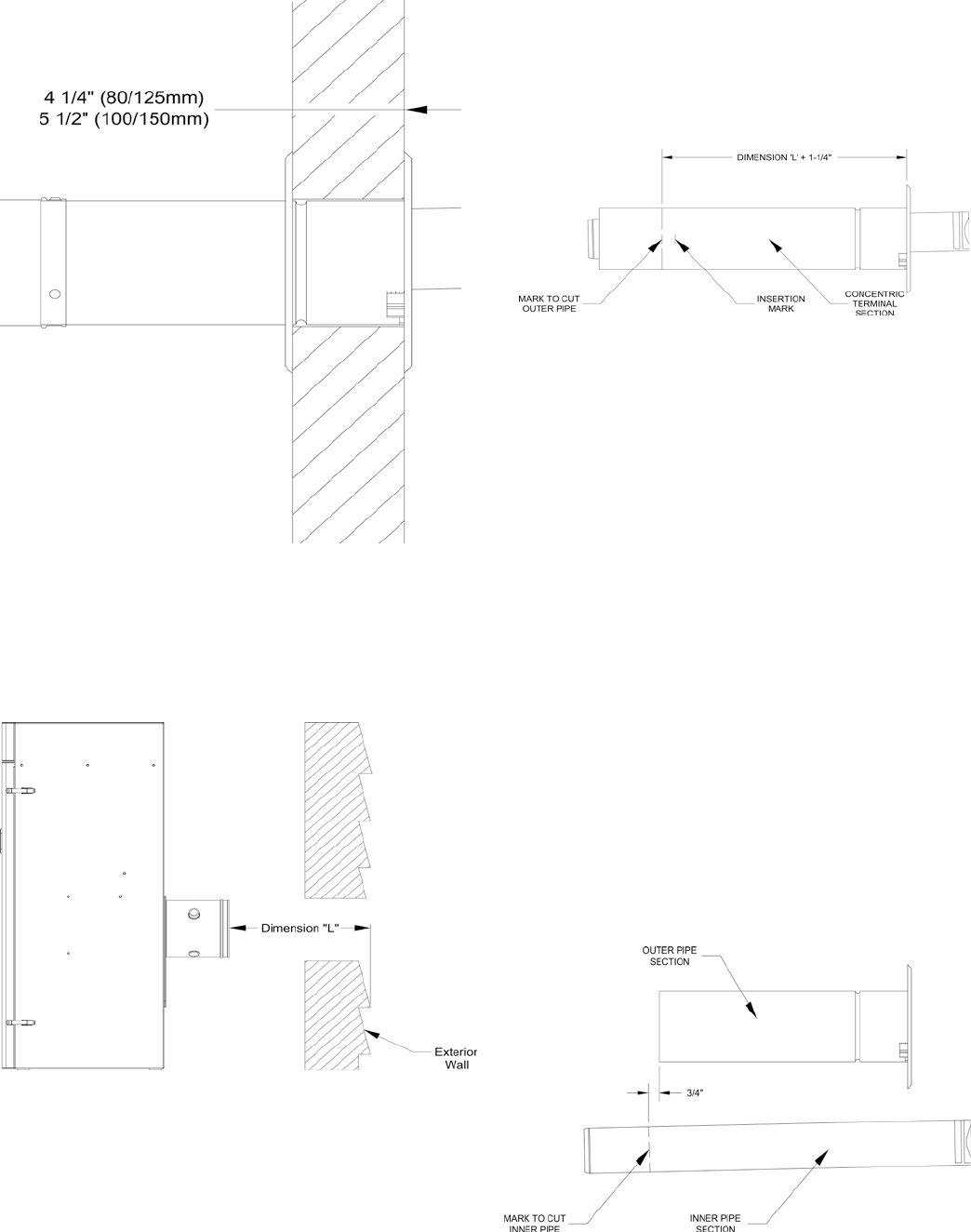

b. Measure dimension “L” from exterior wall outer

surface to the end of the last tting (or end of

installed Boiler Concentric Vent Collar). See

Figure 14 ‘Dimension “L”’.

several marks around the outer pipe to establish a

cut line. See Figure 15 ‘ Cutting Outer Pipe’.

d. Carefully cut the outer pipe at the marked line

using aviation shears, a hacksaw etc. Ensure the

pipe is cut square and cut end is deburred.

Figure 13: Horizontal (Wall) Terminal Installation

Figure 14: Dimension “L”

Figure 15: Cutting Outer Pipe

c.

When factory supplied Horizontal (Wall)

Terminal needs to be shortened, measure

dimension “L” plus 1-¼” from inside of the

attached Outside Wall Plate and mark the

Horizontal (Wall) Terminal outer pipe. To

achieve a square cut of the outer pipe, place

e.

Mark the end of the Horizontal (Wall) Terminal

inner polypropylene vent pipe to extend ¾” past

the cut end of the outer pipe. To achieve a square

cut of the inner pipe, place several marks around

the inner pipe to establish a cut line.

f.

Cut off the marked end of inner polypropylene

vent pipe with a ne tooth blade hacksaw etc.

and deburr. See Figure 16 “Cutting Inner Pipe.

g. Place a mark around the outer pipe, 1” from cut

edge, towards the attached Outside Wall Plate, to

establish visual insertion line as shown in Figure

16 “Cutting Inner Pipe”.

h. Pass the shortened Horizontal Concentric Vent

from outside, thru earlier cut exterior wall

opening and push in until the attached Outside

Wall Plate is tight against exterior wall surface.

Insure the proper position of the Horizontal

Concentric Vent before securing the Outside Wall

Plate to the wall with provided fasteners. Seal

plate edges with exterior grade sealant to prevent

moisture penetration.

Figure 16: Cutting

Inner Pipe