11

D. Install Vent Pipe, General.

1. Start at vent connector. Work toward vent terminal.

2. Use ¾ inch pipe strap to support horizontal runs,

maintain vent location and slope, and prevent sags.

Do not restrict thermal expansion movement.

Maximum support spacing is 5 feet.

3. Provide minimum 5 inch clearance to combustible

materials. Use thimble when penetrating combustible

wall.

a. 203PV and 204PV - Single wall thimble, Burnham

Part No. 8116116. Other wall thimble

manufacturers are American Metal Products, Hart

& Cooley, and Metal Fab.

b. 205PV and 206PV - Double wall thimble, Burnham

Part No. 8116115 (accomodates 5" to 8¾" wall

thickness). Another wall thimble manufacturer is

Hart & Cooley.

4. Cut pipe to length using hacksaw with minimum 32

teeth per inch or circular saw with metal abrasive

wheel. Remove bead end only - bell end accepts next

fitting or pipe. Cut must be square with pipe. Scrape

off burrs with sharp edged tool.

Note: If remaining pipe (less bell) must be used,

beaded end of mating pipe/fitting must be crimped.

5. Seal all joints using Dow Corning Silastic 732 RTV,

Dow Corning Silastic 736 RTV, Polybac #500 RTV, or

Sil-bond RTV 4500 (Acetoxy). Do not use other

adhesives or sealants.

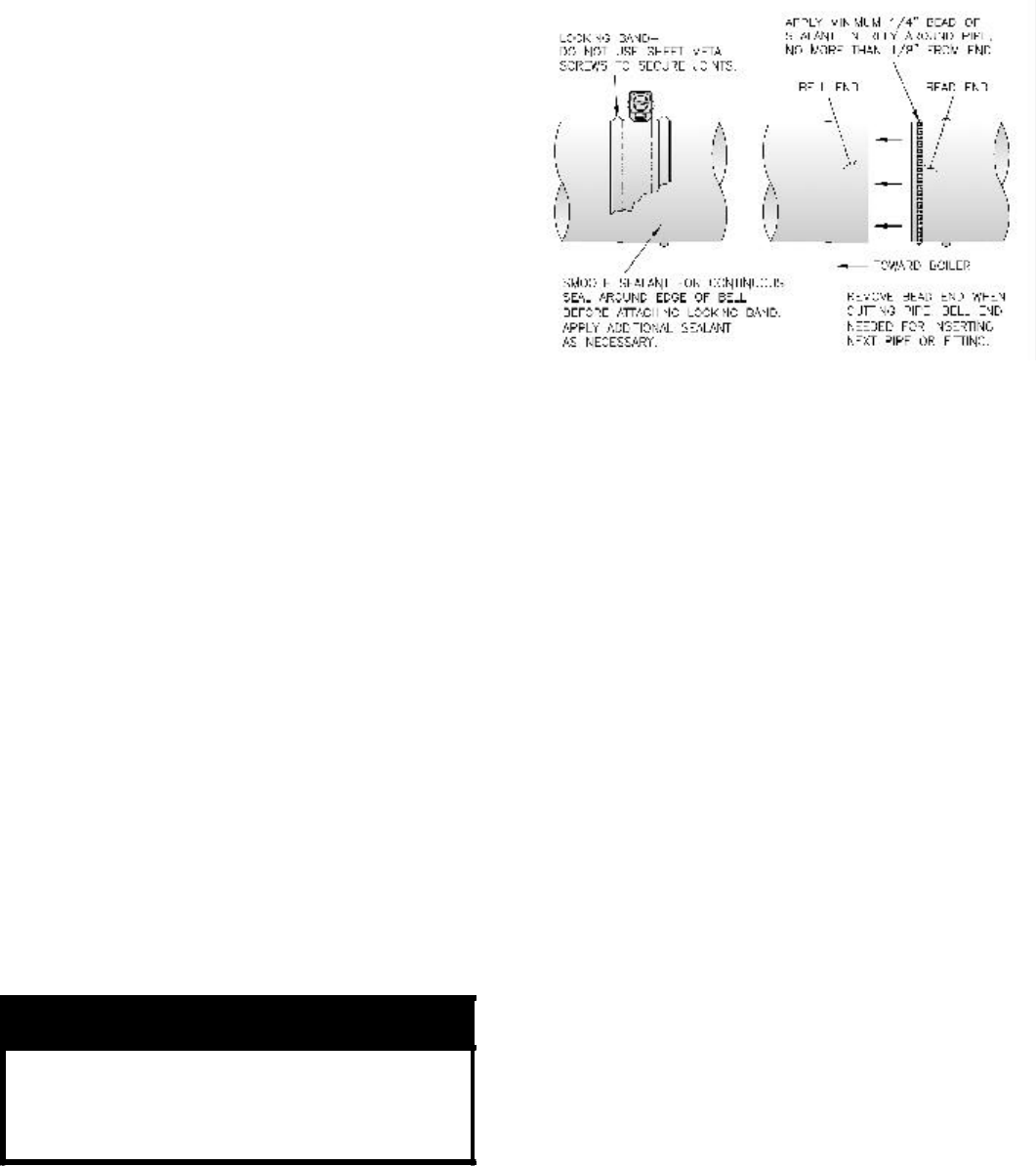

6. Procedure for joining pipe and fittings. See Figure 8.

a. Clean pipe or fitting. Remove all dirt and grease.

b. Slip locking band over pipe/fitting bell.

c. Apply continuous ¼ inch bead of sealant around

bead end of pipe/fitting no more than

1

/8 inch

from end.

d. Insert pipe/fitting into bell. Smooth sealant for

continuous seal around gap between bead and

bell. Apply additional sealant if necessary.

e. Slip locking band over joint and tighten. Do not

secure joint with sheet metal screws or pop rivets.

E. Horizontal (Through Wall) Vent Installation.

1. Maintain minimum ¼ inch per foot slope in

horizontal runs. Slope pipe down toward vent

terminal.

CAUTION

Moisture and ice may form on surfaces

around vent terminal. To prevent

deterioration, surfaces should be in good

repair (sealed, painted etc.)

2. Vent terminal location restricted per following:

a. Minimum 12 inches above grade plus normally

expected snow accumulation level, or 7 feet

above grade if located adjacent to public

walkway. Do not install over public walkway

where local experience indicates condensate or

vapor from Category III appliances creates a

nuisance or hazard.

Figure 8: Typical Joint Detail

b. Minimum 3 feet above any forced air inlet located

within 10 feet.

c. Minimum 4 foot below, 4 foot horizontally from,

or 1 foot above any door, window, or gravity air

inlet.

d. Minimum 4 feet horizontally from, and in no case

above or below, unless a 4-foot horizontal

distance is maintained, from electric meters, gas

meters, regulators and relief equipment.

e. Minimum 12 inches from overhang or corner.

3. Use wall thimble when passing through combustible

outside wall (thimble use optional for

noncombustible wall). Insert thimble through wall

from outside. Secure outside flange to wall with nails

or screws, and seal with adhesive material. Install

inside flange to inside wall, secure with nails or

screws, and seal with adhesive material.

4. For noncombustible wall when thimble is not used,

size opening such that bell with locking band

attached cannot pass through.

5. Join vent terminal to vent pipe. Cut vent pipe to

locate vent terminal 3 inches (minimum) and 6 inches

(recommended) from wall when joined to inside vent

piping. See Figure 9. Vent terminal clearance to vinyl

wall surfaces is 6 inches.

6. Insert vent pipe through thimble/opening from

outside and join to vent system. Apply sealant

between vent pipe and opening/thimble to provide

weathertight seal.