To calculate additional charge requried for a 25-ft line set:

25 ft - 15 ft = 10 ft X 0.6 oz/ft=6ozofadditional charge.

B. COOLING ONLY PROCEDURE

UNITS WITH COOLING MODE PURON® TXV

Units installed with cooling mode TXV require charging by the

subcooling method.

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure liquid service valve pressure by attaching an

accurate gage to service port.

3. Measure liquid line temperature by attaching an accurate

thermistor type or electronic thermometer to liquid line near

outdoor coil.

4. Refer to unit rating plate for required subcooling tempera-

ture.

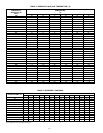

5. Refer to Table 3. Find the point where required subcooling

temperature intersects measured liquid service valve pres-

sure.

6. To obtain required subcooling temperature at a specific

liquid line pressure, add refrigerant if liquid line tempera-

ture is higher than indicated or reclaim refrigerant if

temperature is lower. Allow a tolerance of ± 3°F.

UNITS WITH INDOOR PISTONS

Units installed with indoor pistons require charging by the super-

heat method.

The following procedure is valid when indoor airflow is within ±

21 percent of its rated CFM.

1. Operate unit a minimum of 10 minutes before checking

charge.

2. Measure suction pressure by attaching an accurate gage to

suction valve service port.

3. Measure suction temperature by attaching an accurate

thermistor type or electronic thermometer to suction line at

service valve.

4. Measure outdoor air dry-bulb temperature with thermom-

eter.

5. Measure indoor air (entering indoor coil) wet-bulb tempera-

ture with a sling psychrometer.

6. Refer to Table 4. Find outdoor temperature and evaporator

entering air wet-bulb temperature. At this intersection, note

superheat.

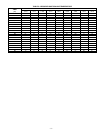

7. Refer to Table 5. Find superheat temperature located in item

6 and suction pressure. At this intersection, note suction line

temperature.

8. If unit has a higher suction line temperature than charted

temperature, add refrigerant until charted temperature is

reached.

9. If unit has a lower suction line temperature than charted

temperature, reclaim refrigerant until charted temperature is

reached.

10. When adding refrigerant, charge in liquid form into suction

service port using a flow-restricting device.

11. If outdoor air temperature or pressure at suction valve

changes, charge to new suction line temperature indicated

on chart.

XIII. FINAL CHECKS

IMPORTANT: Before leaving job, be sure to do the following:

1. Ensure that all wiring and tubing is secure in unit before

adding panels and covers. Securely fasten all panels and

covers.

2. Tighten service valve stem caps to 1/12-turn past finger

tight.

3. Leave User’s Manual with owner. Explain system operation

and periodic maintenance requirements outlined in manual.

4. Fill out Dealer Installation Checklist and place in customer

file.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip-

ment failure, periodic maintenance must be performed on this

equipment.

Frequency of maintenance may vary depending upon geographic

areas, such as coastal applications. See Users Manual for informa-

tion.

—7—