VII. MAKE PIPING CONNECTIONS

WARNING: Relieve pressure and recover all refrigerant

before system repair or final unit disposal to avoid

personal injury or death. Use all service ports and open all

flow-control devices, including solenoid valves.

CAUTION: Do not leave system open to atmosphere

any longer than minimum required for installation. POE

oil in compressor is extremely susceptible to moisture

absorption. Always keep ends of tubing sealed during

installation.

CAUTION: If ANY refrigerant tubing is buried, provide

a 6 in. vertical rise at service valve. Refrigerant tubing

lengths up to 36 in. may be buried without further special

consideration. Do not bury lines over 36 in. in length.

CAUTION: To prevent damage to unit or service valves

observe the following:

• Use a brazing shield.

• Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor section using accessory

tubing package or field-supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 50 ft, substan-

tial capacity and performance losses can occur. Following the

recommendations in the Application Guideline and Service

Manual—Air Conditioners and Heat Pumps Using Puron® Refrig-

erant will reduce these losses. Refer to Table 1 for field tubing

diameters. Refer to Table 2 for accessory requirements.

There are no buried-line applications greater than 36 in.

If refrigerant tubes or indoor coil are exposed to atmosphere, they

must be evacuated to 500 microns to eliminate contamination and

moisture in the system.

A. OUTDOOR UNIT CONNECTED TO FACTORY-

APPROVED INDOOR UNIT

Factory refrigerant charge is for a 15 ft line set. Outdoor unit

contains correct system refrigerant charge for operation with ARI

rated indoor unit. Check refrigerant charge for maximum effi-

ciency. The charge must be adjusted based on the actual line set

length. Add or subtract 0.6 oz/ft for line sets longer or shorter than

15 ft.

B. INSTALL LIQUID-LINE FILTER DRIER

CAUTION: Installation of filter drier in liquid line is

required.

Refer to Fig. 6 and install filter drier as follows:

1. Braze 5-in. connector tube to liquid service valve. Wrap

filter drier with damp cloth.

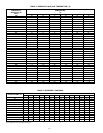

TABLE 1—REFRIGERANT CONNECTIONS AND RECOMMENDED LIQUID AND VAPOR TUBE DIAMETERS (IN.)

UNIT SIZE

LIQUID VAPOR VAPOR (LONG LINE)

Connection Diameter Tube Diameter Connection Diameter Tube Diameter Connection Diameter Tube Diameter

018, 024 3/8 3/8 5/8 5/8 5/8 3/4

030, 036 3/8 3/8 3/4 3/4 3/4 7/8

042, 048 3/8 3/8 7/8 7/8 7/8 1-1/8

060 3/8 3/8 7/8 1-1/8 7/8 1-1/8

NOTES:

1. Tube diameters are forlengths up to50 ft. For tubing lengthsgreater than 50 ft, consultthe Application Guideline and ServiceManual—Air Conditioners and Heat Pumps

Using Puron®.

2. Do not apply capillary tube indoor coils to these units.

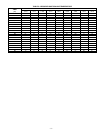

TABLE 2—ACCESSORY USAGE

ACCESSORY

REQUIRED FOR

LOW-AMBIENT

APPLICATIONS

(BELOW 55°F)

REQUIRED FOR

LONG-LINE

APPLICATIONS*

(OVER 50 FT)

REQUIRED FOR

SEA COAST

APPLICATIONS

(WITHIN 2 MILES)

Crankcase Heater Yes Yes No

Evaporator Freeze Thermostat Yes No No

Winter Start Control Yes† No No

Accumulator No No No

Compressor Start Assist

Capacitor and Relay

Yes Yes No

MotorMaster® Control,

or

Low-Ambient Pressure Switch

Yes No No

Wind Baffle See Low-Ambient Instructions No No

Coastal Filter No No Yes

Support Feet Recommended No Recommended

Liquid-Line Solenoid Valve

or

Hard Shutoff TXV

No See Long-Line Application Guideline No

Ball Bearing Fan Motor Yes‡ No No

* For Tubing Sets between 50 and 175 ft, refer to the Application Guideline and Service Manual—Air Conditioners and Heat Pumps Using Puron®.

† Only when low-pressure switch is used.

‡ Required for low-ambient controller (full modulation feature) and MotorMaster® Control only.

—4—

→

→

→