CAUTION: Combustion air must not be taken from

inside structure because that air is frequently contami-

nated by halogens, which include fluorides, chlorides,

bromides, and iodides. These elements are found in

aerosols, detergents, bleaches, cleaning solvents, salts, air

fresheners, adhesives, paint, and other household prod-

ucts. Locate combustion-air inlet as far as possible from

swimming pool and swimming pool pump house.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

WARNING: Solvent cements are combustible. Keep

away from heat, sparks, and open flame. Use only in well

ventilated areas. Avoid breathing in vapor or allowing

contact with skin or eyes. Failure to follow this warning

could result in fire, property damage, personal injury, or

death.

WARNING: All combustion-air and vent pipes must be

airtight and watertight. Pipes must also terminate exactly

as shown in Fig. 31, 32, 33, 34, or 35. Failure to follow

this warning could result in property damage, personal

injury, or death.

NOTE: The minimum combustion-air and vent pipe length (each)

for these furnaces is 5 ft. Short pipe lengths (5-8 ft) may discharge

water droplets. These droplets may be undesirable, and a 12-in.

minimum offset pipe section is recommended, as shown in Fig. 29,

to reduce excessive droplets from exiting vent pipe outlet.

B. Combustion-Air and Vent Pipe Diameter

Determine combustion-air and vent pipe diameter.

1. Using Table 6, individually determine the combustion-air

and vent pipe diameters. Pick the larger of these 2 pipe

diameters and use this diameter for both combustion-air and

vent pipes.

2. When installing vent systems of short pipe length, use the

smallest allowable pipe diameter. Do not use pipe size

greater than required or incomplete combustion, flame

disturbance, or flame sense lockout may occur.

NOTE: Do not count elbows or pipe sections in terminations or

within furnace. See shaded areas in Fig. 31, 32, 33, 34, and 35.

TABLE 5—COMBUSTION-AIR AND VENT PIPE

TERMINATION CLEARANCES

LOCATION

CLEARANCE (FT)

U.S.A. Canada

Above grade level or above antici-

pated snow depth

11†

Dryer vent 33

From plumbing vent stack 33

From any mechanical fresh air intake 16

For furnaces with an input capacity

less than 100,000 Btuh—from any

non-mechanical air supply (windows

or doors which can be opened) or

combustion-air opening

11

For furnaces with an input capacity

greater than 100,000 Btuh—from any

non-mechanical air supply (windows

or doors which can be opened) or

combustion-air opening

13

From service regulator vent, electric

and gas meters, and relief equipment

4* 6‡

Above grade when adjacent to public

walkway

77

* Horizontal distance.

† 18 in. above roof surface in Canada.

‡ 36 in. to electric meter in Canada only.

NOTES:

1. If installing 2 adjacent 355MAV Furnaces, refer to Multiventing and Vent

Terminations section for proper vent configurations.

2. Whenlocating combustion-air and vent terminations, consideration must be

given to prevailing winds, location, and other conditions which may cause

recirculation of the appliance’s own flue products or the flue products of

adjacent vents. Recirculation can cause poor combustion, inlet condensate

problems, and accelerated corrosion of heat exchangers.

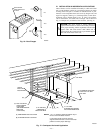

Fig. 27—Combustion-Air and Vent Pipe Diameter

Transition Location and Elbow Configuration

A93034

FURNACE

PIPE DIAMETER

TRANSITION IN

VERTICAL SECTION

NOT IN

HORIZONTAL

SECTION

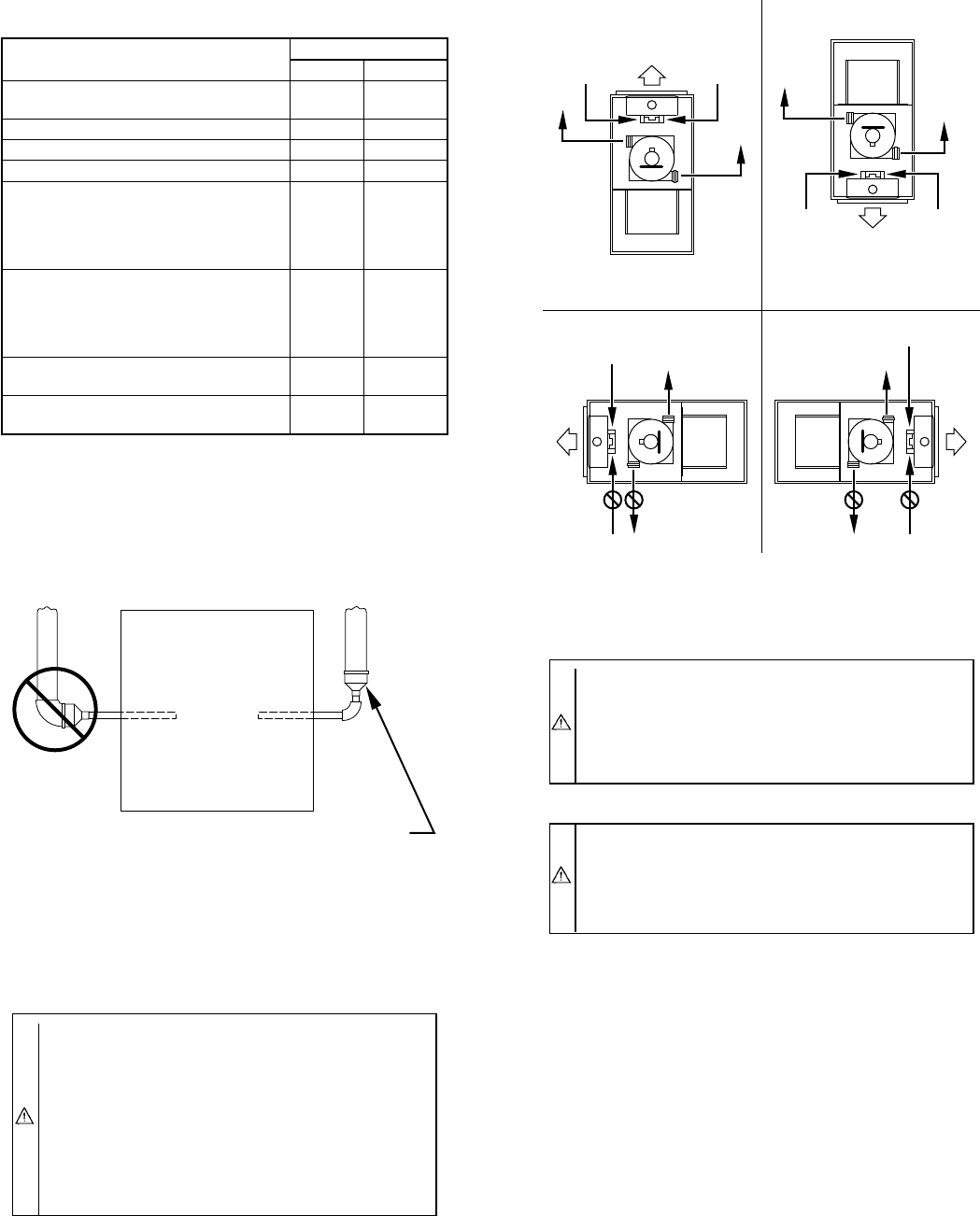

Fig. 28—Combustion-Air and Vent Pipe Connections

A96187

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW DOWNFLOW

HORIZONTAL-LEFT DISCHARGE HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

VENT

VENT

VENT

NOTE: Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

—22—