5. Route this extended tube (pink label) to condensate trap

relief port connection.

6. Determine appropriate length, cut, and connect tube.

7. Clamp tube to relief port connection.

E. Condensate Trap Freeze Protection

Refer to Condensate Drain Protection section for recommenda-

tions and procedures.

F. Construct a Working Platform

Construct working platform where all required furnace clearances

are met. (See Fig. 3 and 10.)

CAUTION: The condensate trap MUST be installed

below furnace. See Fig. 4 for dimensions. The drain

connection to condensate trap must also be properly

sloped to an open drain.

NOTE: Combustion-air and vent pipes are restricted to a mini-

mum length of 5 ft. (See Table 6.)

NOTE: A 12-in. minimum offset pipe section is recommended

with short (5 to 8 ft) vent systems. This recommendation is to

reduce excessive condensate droplets from exiting the vent pipe.

(See Fig. 10 or 29.)

LOCATION

I. GENERAL

When a furnace is installed so that supply ducts carry air to areas

outside the space containing the furnace, return air must also be

handled by ducts sealed to furnace casing. The ducts terminate

outside the space containing the furnace to ensure there will not be

a negative pressure condition within equipment room or space.

Furnace may be located in a confined space without special

provisions for dilution or ventilation air. This furnace must be

installed so electrical components are protected from water.

Locate furnace as close to center of air distribution system as

possible.

Locate furnace so combustion-air pipe lengths are not exceeded.

Refer to Table 6.

CAUTION: If these furnaces are used during construc-

tion when adhesives, sealers, and/or new carpets are

being installed, make sure all combustion and circulating

air requirements are followed. If operation of furnace is

required during construction, use clean outside air for

combustion and ventilation. Compounds of chlorine and

fluorine, when burned with combustion air, form acids

which will cause corrosion of heat exchangers. Some of

these compounds are found in paneling, dry wall adhe-

sives, paints, thinners, masonry cleaning materials, and

many other solvents commonly used in the construction

process.

Excessive exposure to contaminated combustion air will

result in safety and performance related problems.

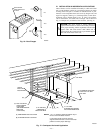

Fig. 11—Horizontal Right Tube Configuration

A93354

PLUG

COLLECTOR BOX DRAIN TUBE

(BLUE AND WHITE STRIPED)

INDUCER HOUSING

DRAIN TUBE (VIOLET)

COLLECTOR BOX

EXTENSION TUBE

COLLECTOR BOX TUBE (GREEN)

CAP

COLLECTOR BOX DRAIN TUBE (BLUE)

COLLECTOR BOX TUBE (PINK)

CONDENSATE

TRAP

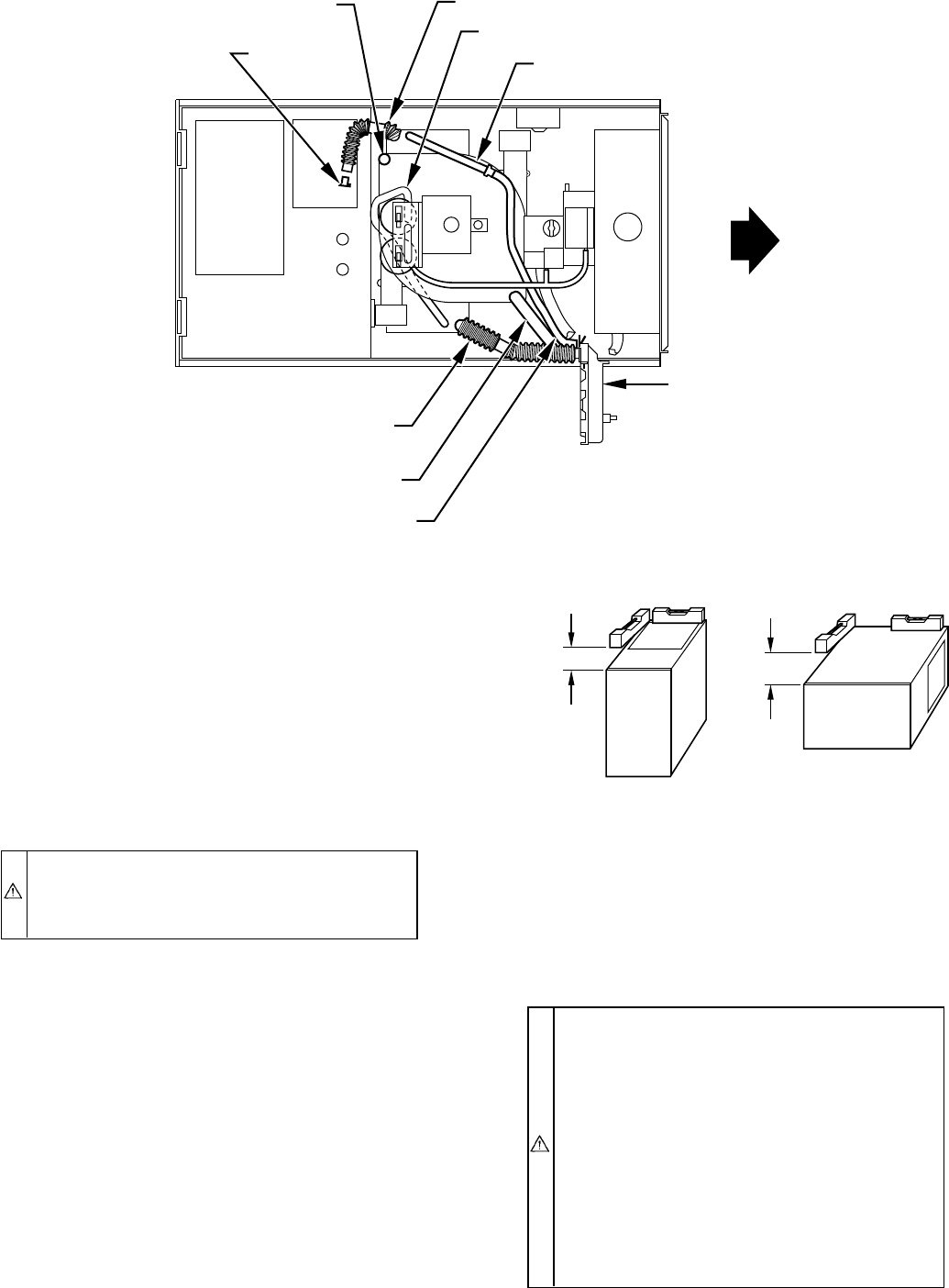

NOTE: For proper furnace operation, install furnace so that it is

level or pitched forward within 1/2 in. to ensure proper condensate

drainage from secondary heat exchangers.

A93025

UPFLOW OR DOWNFLOW HORIZONTAL

FRONT

LEVEL (0″)

TO

1

⁄2″ MAX

LEVEL (0″)

TO

1

⁄2″ MAX

FRONT

—11—