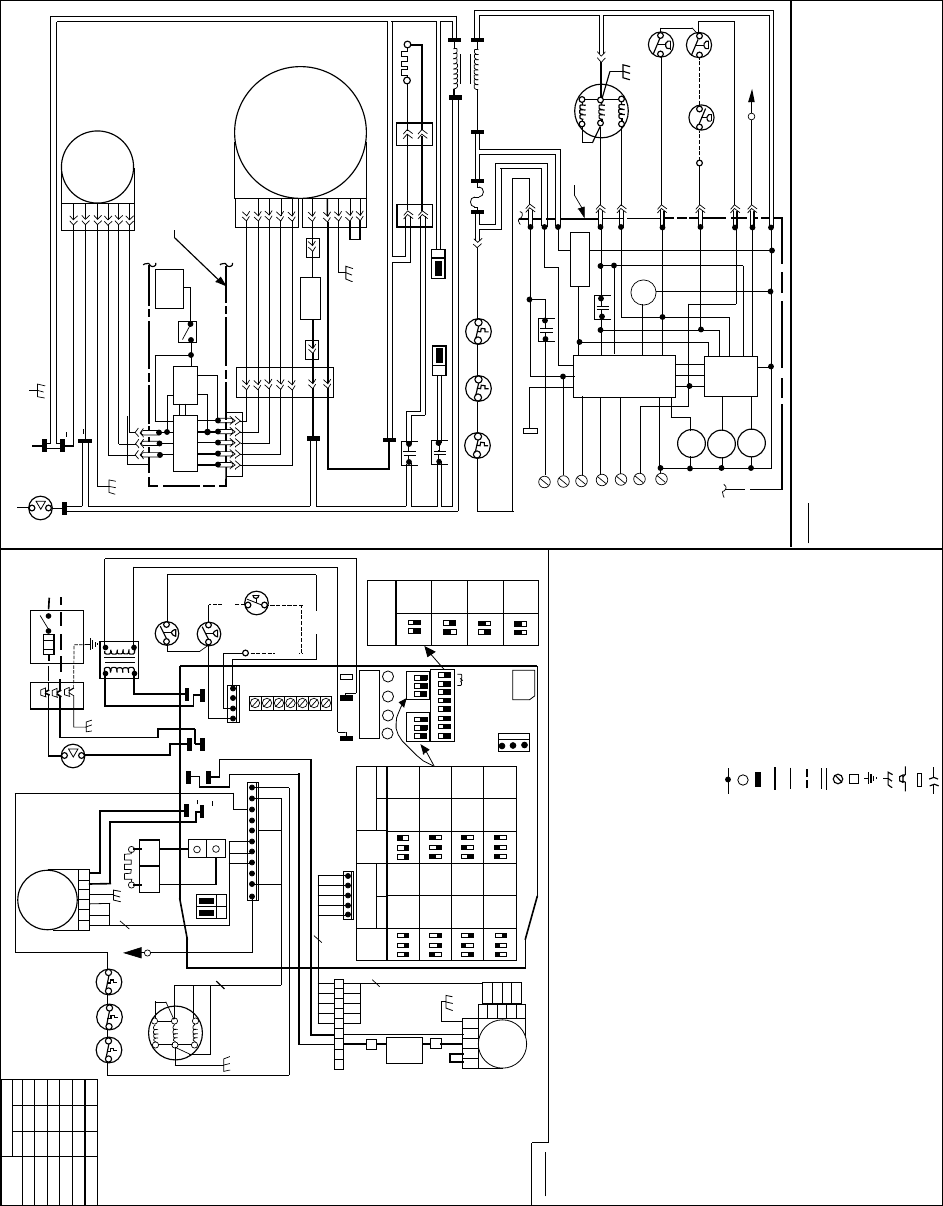

Fig. 24—Wiring Diagram

A96276

FRS

LS

ALS

FSE

GV

RED

C

M

P

BLU

BRN

GRN

HI

GRN

NOTE #3

3

RED

WHT

WHT

PL1

PL7

12104 612

ORN

BRN

YEL

GRN

BLK

WHT

3

PL9

HSI

12

1.5 AMP

EAC1

EAC2

BLK

WHT

2

1

PL4

BLK

123

7

8

456

YEL

ORN

BRN

GRN

BLU

BRN

RED

BLK

WHT

WHT

RED

10 11

B2

RED

9

BLK

WHT

5

PL3

5BLU

4YEL

3VIO

2ORN

1RED

RED

ORN

VIO

YEL

BLU

WHT

BLK

RED

ORN

VIO

YEL

BLU

987654321

PL10

1

PL11

5

IND.

NOTE #7

PL11

PL12

12543

3

16

8

14

1

RED

ORN

VIO

YEL

BLK

WHT

GRN

YEL

BLU

MTR2

6

PL13

SWITCH

POS.

A/C AND CF

SELECTION CHART

SWITCH

POS.

A/C AND CF

SELECTION CHART

A/C CF A/C CF

DEFAULT

DEFAULT

1-1/2

TON

2

TON

2-1/2

TON

1000

CFM

800

CFM

600

CFM

3

TON

1200

CFM

3-1/2

TON

1400

CFM

4

TON

1600

CFM

5

TON

2000

CFM

PCB

PL6

FU1

LEDS

(1-4)

SW

(1-8)

FUSE

24VAC-3A

1

234

CF A/C

123 123

12

3

45

6

7

8

FLT

LOW HEAT

BPH

EMER. HEAT

MZ

COMP. TEST

BLOWER

OFF-DELAY

PL5

321

654

BLOWER

OFF-DELAY

SELECTION CHART

90

SEC.

135

SEC.

180

SEC.

225

SEC.

78

OFF

NOTE #6

78

OFF

78

OFF

7

8

OFF

SEC-2

SEC-1

DH

RED

BLUE

HUM

G

R

Y/Y2

W/W1

C

W2

1234

PL2

ORN

L2

L1

P2

P1

YEL

YEL

NO

C

LPS

TRAN HPS

C

NO

BLUE

ILK

WHT

BLK

WHT

BLK

BLK

WHT

GRN

JB

BLK

WHT

GRN

FU2

FUSED DISCONNECT

SWITCH (WHEN REQ’D)

NOTE #2

MTR1

LEGEND

A/C AIR CONDITIONING (ADJUSTABLE TONNAGE)

ALS AUXILIARY LIMIT SWTICH OVERTEMP - MANUAL RESET SPST-(N.C)

CF CONTINUOUS FAN (ADJUSTABLE CFM)

CPU1 MAIN MICROPROCESSOR & CIRCUITRY

CPU2 IGNITION MICROPROCESSOR & CIRCUITRY

DH DEHUMIDIFICATION CONNECTION (24VAC .02 AMPS)

EAC-1 ELECTRONIC AIR CLEANER CONNECTION (115 VAC 1.5 AMP MAX.)

EAC-2 ELECTRONIC AIR CLEANER CONNECTION (COMMON)

FRS FLAME ROLLOUT SWITCH - MANUAL RESET, SPST-(N.C.)

FSE FLAME PROVING SENSOR ELECTRODE

FU1 FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FACTORY INSTALLED

FU2 FUSE OR CIRCUIT BREAKER CURRENT INTERRUPT DEVICE (FIELD INSTALLED & SUPPLIED)

GV GAS VALVE

GVR GAS VALVE RELAY, DPST-(N.O.)

HI GAS VALVE HIGH STAGE OPERATOR

HPS HIGH HEAT PRESSURE SWITCH, SPST-(N.O.)

HSI HOT SURFACE IGNITOR (115 VAC)

HSIR HOT SURFACE IGNITOR RELAY, SPST-(N.O.)

HUM 24VAC HUMIDIFIER CONNECTION (.5 AMP. MAX.)

HUMR HUMIDIFIER RELAY, SPST-(N.O.)

ILK BLOWER ACCESS PANEL INTERLOCK SWITCH, SPST-(N.O.)

IND INDUCTOR (NOTE #7)

JB JUNCTION BOX

LEDS LIGHT EMITTING DIOES FOR STATUS CODES

LGPS LOW GAS PRESSURE SWITCH, SPST (N.O.)

LPS LOW HEAT PRESSSURE SWITCH, SPST-(N.O.)

LS LIMIT SWITCH, AUTO RESET, (N.C.)

MTR1 MOTOR (ICM) INDUCER

MTR2 MOTOR (ICM) BLOWER

PCB PRINTED CIRCUIT BOARD

PL1 11-CIRCUIT CONNECTOR

PL2 4-CIRCUIT PRESSURE SWITCH CONNECTOR

PL3 5-CIRCUIT BLOWER MTR CONNECTOR

PL4 2-CIRCUIT HSI CONNECTOR

PL5 6-CIRCUIT MODEL PLUG

PL6 3-CIRCUIT COMM. CONNECTOR

PL7 12-CIRCUIT INDUCER MTR CONNECTOR

PL9 2-CIRCUIT HSI CONNECTOR

PL10 9-CIRCUIT BLOWER ADAPTER CONNECTOR

PL11 1-CIRCUIT INDUCTOR SPLICE CONNECTOR

PL12 5-CIRCUIT BLOWER POWER CONNECTOR

PL13 16-CIRCUIT BLOWER CTRL. CONNECTOR

SW1 MANUAL SWITCH, FAULT DISPLAY, SPST-(N.O.)

SW2 MANUAL SWITCH, LOW HEAT, SPST-(N.O.)

SW3 MANUAL SWITCH, BYPASS HUMIDIFIER, SPST-(N.O.)

SW4 MANUAL SWITCH, EMERGENCY HEAT, SPST-(N.O.)

SW5 MANUAL SWITCH, MULTIPLE ZONE, SPST-(N.O.)

SW6 COMPONENT TEST, SPST-(N.O.)

SW7-8 MANUAL SWITCH, BLOWER OFF-DELAY, SPST-(N.O.)

TRAN TRANSFORMER - 115VAC/24VAC

JUNCTION

UNMARKED TERMINAL

PCB TERMINAL (FACTORY CONNECTED)

FACTORY WIRING (115 VAC)

FACTORY WIRING (24 VAC)

FIELD WIRING (115 VAC)

CONDUCTOR ON PCB

FIELD WIRING SCREW TERMINAL

TERMINAL BLOCK - MARKED TERMINAL

FIELD GROUND

EQUIPMENT GROUND

FIELD SPLICE

PCB TERMINAL (FIELD CONNECTION)

PLUG RECEPTACLE

NOTE #2

L1

L2

L2

L1

EQUIPMENT GROUND

PL1

654

PL7

MTR1

12

6

4

1

2

10

D.C.

POWER

SUPPLY

PCB

NOTE #5

SW - 4

EMER. HEAT

SCHEMATIC DIAGRAM

(NATURAL GAS & PROPANE)

PL13

CPU1

CPU2

PL3

12345

B1 7

6

1

2

3

4

5

PL11

PL10

IND

NOTE #7

B2

PL11

PL12

6

14

8

16

3

5

4

3

2

1

MTR2

HSIR

EAC

FRS

LS

ALS

PL1-9

EAC-1 EAC-2

PL4

PL9

HSI

NOTE #6

FU1

SEC-1

24VAC

SEC-2

TRAN

P1

115VAC

P2

PL1-11

PCB

NOTE #5

HUMR

D.C. POWER

SUPPLY

DH

HUM

R

G

Y/Y2

W2

W/W1

C

PL1-1

PL2-1

PL2-2

PL2-4

PL1-10

PL1-2

EAC

GVR

GV

P

C

M

HI

NOTE #3

HPS

NO

C

PL1-7

FSE

LPS

CPU2

CPU1

NOTES:

322296-101 REV. B

1. If any of the original equipment wire is replaced use wire rated for 105°C.

2. Use only copper wire between the disconnect switch and the furnace junction box (JB).

3. This wire must be connected to furnace sheet metal for control to prove flame.

4. Symbols are electrical representation only.

5. Solid lines, inside circuit board PCB are printed circuit board traces and are not depicted as shown in the legend.

6. Replace only with a 3 AMP fuse.

7. Inductor used on all 060 or -20 airflow units.

8. Blower-on delay, gas heating 60 seconds low heat, 35 seconds high heat, cooling or heat pump 2 seconds..

9. Blower-off delay, gas heating 90, 135, 180 or 225 seconds, cooling or heat pump 90 seconds.

10. Ignition-lockout will occur after four consecutive unsuccessful trials-for-ignition.

Control will auto-reset after three hours.

11. Factory connected when LGPS not used.

HUMR

HSIR

GVR

OM

T 2

T 1

T 2

T 1

OM

213

OFF

213

OFF

213

OFF

213

OFF

213

OFF

213

OFF

213

OFF

213

OFF

1

C

NO

2

1

2

1

TO 115 VAC FIELD DISCONNECT

B1

RED

ILK

MODEL

JUMPERS

1-4 2-5 3-6

X

X

XX

X

042040

042060

042080

060100

SIZE

060080

060120

XX

XX

ORN

BRN

LGPS

(WHEN USED)

ORN

NOTE #11

NOTE #11

LGPS

NOTE #11

(WHEN USED)

NOTE #11

—19—