This gas furnace may be used for construction heat provided

that:

-The furnace is permanently installed with all electrical

wiring, piping, venting and ducting installed according to

these installation instructions. A return air duct is provided,

sealed to the furnace casing, and terminated outside the space

containing the furnace. This prevents a negative pressure

condition as created by the circulating air blower, causing a

flame rollout and/or drawing combustion products into the

structure.

-The furnace is controlled by a thermostat. It may not be ″hot

wired″ to provide heat continuously to the structure without

thermostatic control.

-Clean outside air is provided for combustion. This is to

minimize the corrosive effects of adhesives, sealers and other

construction materials. It also prevents the entrainment of

drywall dust into combustion air, which can cause fouling and

plugging of furnace components.

-The temperature of the return air to the furnace is no less

than 55 degrees F, with no evening setback or shutdown. The

use of the furnace while the structure is under construction is

deemed to be intermittent operation per our installation

instructions.

-The air temperature rise is within the rated rise range on the

furnace rating plate, and the firing rate has been set to the

nameplate value.

-The filters used to clean the circulating air during the

construction process must be either changed or thoroughly

cleaned prior to occupancy.

-The furnace, ductwork and filters are cleaned as necessary to

remove drywall dust and construction debris from all HVAC

system components after construction is completed.

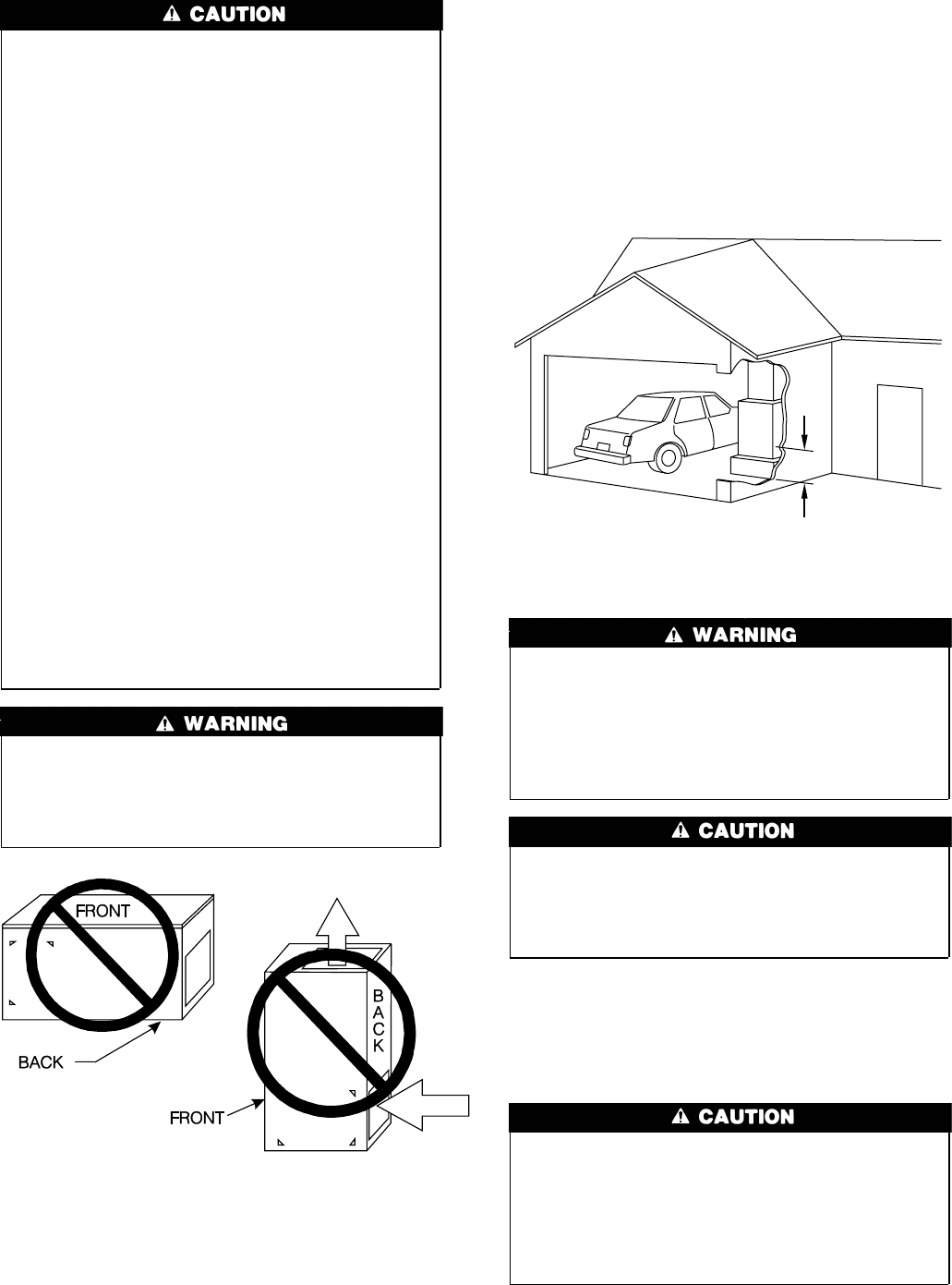

DO NOT install the furnace on its back or facing down.

Safety control operation will be adversely affected. Never

connect return-air ducts to back of furnace. Failure to follow

this warning could result in fire, personal injury, or death.

(See Fig. 5.)

Step 2—Location Relative to Cooling Equipment

The cooling coil must be installed parallel with, or on the

downstream side of the unit to avoid condensation in the heat

exchangers. When installed parallel with the furnace, dampers or

other flow control must prevent chilled air from entering the

furnace. If the dampers are manually operated, they must be

equipped with means to prevent operation of either unit unless the

damper is in the full-heat or full-cool position.

AIR FOR COMBUSTION AND VENTILATION

Provisions for adequate combustion and ventilation air must be

provided in accordance with Section 5.3 of the NFGC, Air for

Combustion and Ventilation, or applicable provisions of the local

building codes.

Canadian installations must be installed in accordance with NSC-

NGPIC Part 7 and all authorities having jurisdiction.

When the furnace is installed in a residential garage, the

burners and ignition sources must be located at least 18 inches

above the floor. The furnace must be located or protected to

avoid damage by vehicles. When the furnace is installed in a

public garage, airplane hangar, or other building having a

hazardous atmosphere, the furnace must be installed in

accordance with the NFGC or NSCNGPIC. (See Fig. 6.)

Air for combustion must not be contaminated by halogen

compounds, which include fluoride, chloride, bromide, and

iodide. These elements are found in aerosol sprays, deter-

gents, bleaches, cleaning solvents, salts, air fresheners, and

other household products.

All fuel-burning equipment must be supplied with air for fuel

combustion. Sufficient air must be provided to avoid negative

pressure in the equipment room or space. A positive seal must be

made between the furnace cabinet and the return-air duct to

prevent pulling air from the burner area and from blocked vent

safeguard opening.

The operation of exhaust fans, kitchen ventilation fans,

clothes dryers, attic exhaust fans or fireplaces could create a

NEGATIVE PRESSURE CONDITION at the furnace.

Make-up air MUST be provided for the ventilation devices, in

addition to that required by the furnace. Refer to Carbon

Monoxide Hazard warning in venting section of these instruc-

tions to determine amount of make-up air required.

The requirements for combustion and ventilation air depend upon

whether the furnace is located in an unconfined or confined space.

Fig. 5—Prohibit Installation on Back

A02054

Fig. 6—Installation in a Garage

A93044

18-IN. MINIMUM

TO BURNERS

6

→

→