Downflow Furnaces

Connect supply-air duct to supply-air opening on furnace. The

supply-air duct attachment must ONLY be connected to furnace

supply/outlet or air conditioning coil casing (when used). When

installed on combustible material, supply-air duct attachment must

ONLY be connected to the accessory subbase, KGASB0201ALL,

or factory approved air conditioning coil casing. DO NOT cut

main furnace casing to attach supply side air duct, humidifier, or

other accessories. All accessories MUST be connected external to

furnace casing.

RETURN AIR CONNECTIONS

Never connect return-air ducts to the back of the furnace. A

failure to follow this warning can cause a fire, personal injury,

or death.

Downflow Furnaces

The return-air duct must be connected to return-air opening

(bottom inlet) as shown in Fig. 1. DO NOT cut into casing sides

(left or right). Side opening is permitted for only upflow and most

horizontal furnaces. Bypass humidifier connections should be

made at ductwork or coil casing sides exterior to furnace.

Upflow and Horizontal Furnaces

The return-air duct must be connected to bottom, sides (left or

right), or a combination of bottom and side(s) of main furnace

casing as shown in Fig. 1. Bypass humidifier may be attached to

unused side return air portion of the furnace casing. (See Fig. 18,

19, and 20.)

Not all horizontal furnaces are approved for side return air

connections. (See Fig. 20.)

Step 6—Gas Piping

Never purge a gas line into a combustion chamber. Never test

for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection of

leaks to check all connections. A failure to follow this

warning could result in fire, explosion, personal injury, or

death.

Gas piping must be installed in accordance with national and local

codes. Refer to current edition of NFGC in the U.S., the NSCNG-

PIC in Canada.

Installations must be made in accordance with all authorities

having jurisdiction. If possible, the gas supply line should be a

separate line running directly from meter to furnace.

Refer to Table 4 for recommended gas pipe sizing. Risers must be

used to connect to furnace and to meter. Support all gas piping

with appropriate straps, hangers, etc. Use a minimum of 1 hanger

every 6 ft. Joint compound (pipe dope) should be applied sparingly

and only to male threads of joints. Pipe dope must be resistant to

the action of propane gas.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do not use a

connector which has previously serviced another gas appli-

ance. Black iron pipe shall be installed at the gas valve and

extend a minimum of 2-in. outside the furnace.

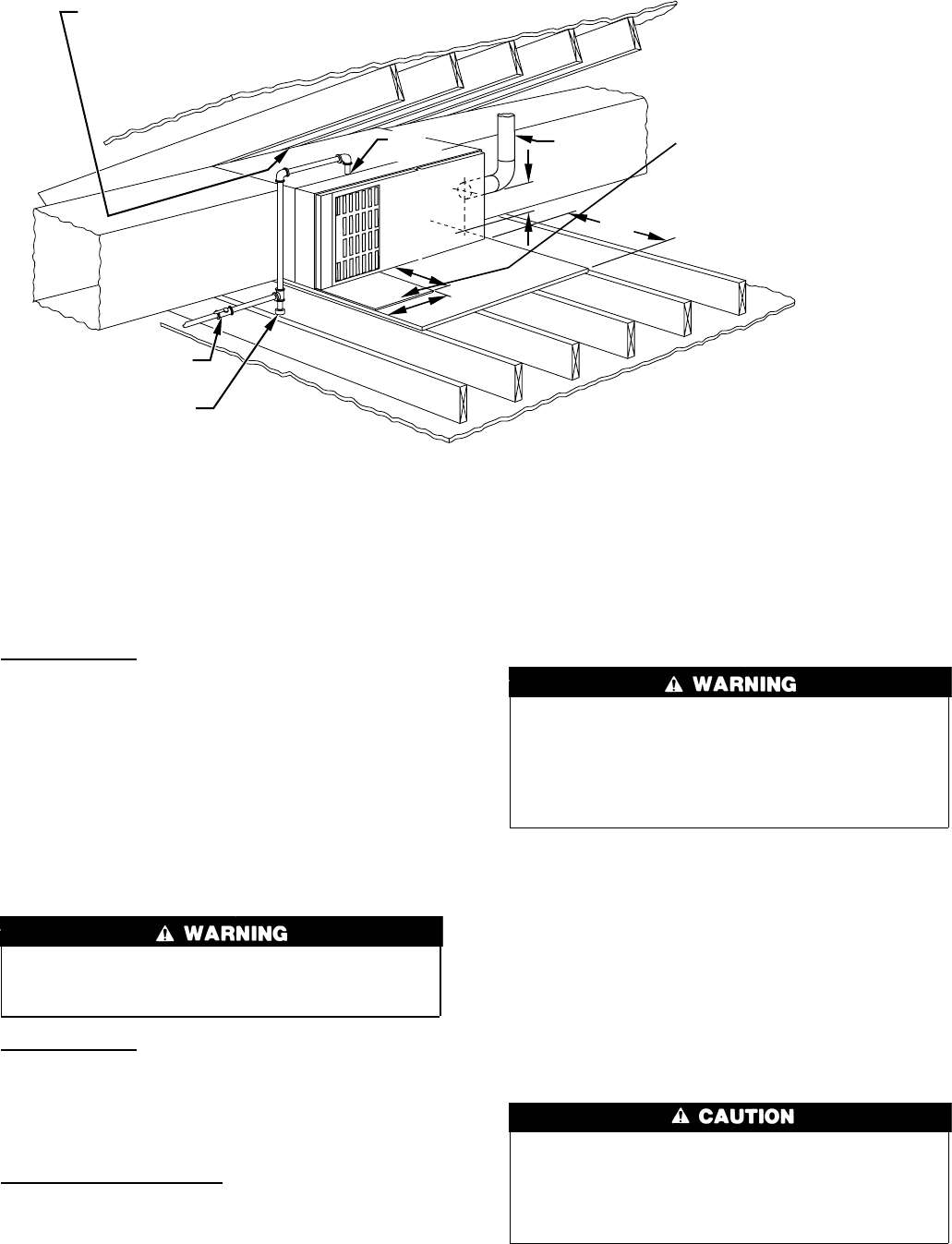

Fig. 17—Typical Attic Installation

A02164

30-IN. MIN

WORK AREA

6″

MIN*

TYPE-B

VENT

17

3

/4

″

22

″

SHEET

METAL

SEDIMENT

TRAP

MANUAL SHUTOFF

GAS VALVE

LINE CONTACT ONLY PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE TOP AND TWO SIDES OF THE FURNACE

JACKET AND BUILDING JOISTS,

STUDS, OR FRAMING.

GAS

ENTRY

17

3

/4

″ OVER ALL

4

3

/4

″ UNDER DOOR

1″ UNDER FURNACE

EXTEND OUT 12″ OUT

FROM FACE OF DOOR

* WHEN USED WITH

SINGLE WALL VENT

CONNECTIONS

13

→

→