4. Verify natural gas input rate by clocking meter.

NOTE: Gas valve regulator adjustment cap must be in place for

proper input to be clocked.

a. Turn off all other gas appliances and pilots.

b. Run furnace for 3 minutes in heating operation.

c. Measure time (in sec) for gas meter to complete 1 revolu-

tion and note reading. The 2 cubic feet dial provides a more

accurate measurement of gas flow.

d. Refer to Table 8 for cubic ft of gas per hr.

e. Multiply gas rate (cu ft/hr) by heating value (Btu/cu ft) to

obtain input.

If clocked rate does not match required input from Step 1, increase

manifold pressure to increase input or decrease manifold pressure

to decrease input. Repeat steps b through e until correct input is

achieved. Re-install regulator seal cap on gas valve.

5. Set temperature rise.

The furnace must operate within the temperature rise ranges

specified on the furnace rating plate. Do not exceed tempera-

ture rise range specified on unit rating plate. Determine the

temperature rise as follows:

a. Place thermometers in return and supply ducts as close to

furnace as possible. Be sure thermometers do not see

radiant heat from heat exchangers. Radiant heat affects

temperature rise readings. This practice is particularly

important with straight-run ducts.

b. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine air

temperature rise.

NOTE: Blower access door must be installed for proper tempera-

ture rise measurement.

NOTE: If the temperature rise is outside this range, first check:

1.) Gas input for heating operation.

2.) Derate for altitude if applicable.

3.) Return and supply ducts for excessive restrictions causing static

pressures greater than 0.50-in. wc.

4.) Dirty filter.

Disconnect 115-v electrical power before changing speed tap.

Failure to follow this warning could result in personal injury.

c. Adjust air temperature rise by adjusting blower speed.

Increase blower speed to reduce temperature rise. Decrease

blower speed to increase temperature rise.

d. Turn thermostat down below room temperature and re-

move blower access door.

e. To change motor speed selection for heating, remove

blower motor lead from control HEAT terminal (See Fig.

39.) Select desired blower motor speed lead from one of the

other terminals and relocate it to the HEAT terminal (See

Table 7 for lead color identification). Reconnect original

lead to SPARE terminal.

f. Repeat steps a through e.

g. When correct input rate and temperature rise is achieved,

turn gas valve ON/OFF switch to OFF.

h. Remove manometer or similar device from gas valve.

i. Re-install manifold pressure tap plug in gas valve.

Failure to reinstall manifold pressure tap plug in gas valve

will result in fire, explosion, personal injury, property damage

or death.

j. Re-install blower access door if removed.

k. Turn gas valve ON/OFF switch to ON.

Recheck temperature rise. It must be within limits specified

on the rating plate. Recommended operation is at the mid-

point of rise range or slightly above

6. Set thermostat heat anticipator.

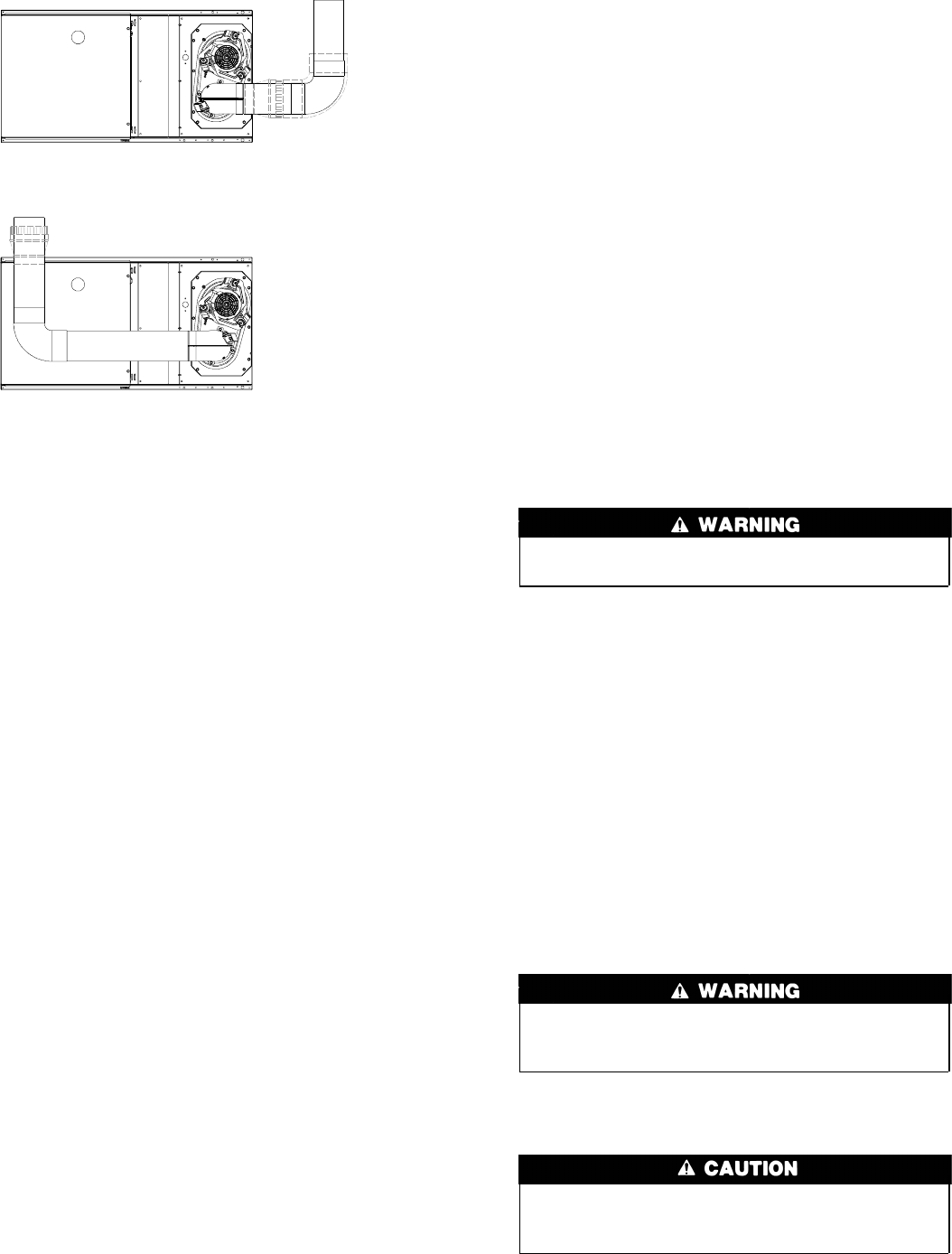

Fig. 37—Horizontal Right Application-Vent Elbow

Right

A02069

SEE NOTES: 1,2,4,7,8,9

SEE NOTES: 1,2,4,5,7,8,9

A02070

Fig. 38—Horizontal Right Application-Vent Elbow Left

then Up

Venting Notes for Fig. 26-38

1. For common vent, vent connector sizing and vent material: United

States, latest edition of the National Fuel Gas Code (NFGC), ANSI

Z223.1/NFPA 54. In Canada, latest edition of the National Standards

of Canada, Natural Gas and Propane Installation Code (NSCNGPIC),

CSA B149.1-00.

2. Immediately increase to 5–inch vent connector outside furnace

casing when 5-inch vent connector required, refer to Note 1 above.

3. Side outlet vent for upflow and downflow installations must use

Type B vent immediately after exiting the furnace, except when

KGAVG0101DFG is used in the downflow position.

4. Type B vent where required, refer to Note 1 above.

5. 4” single wall (26 ga. min.) vent must be used inside furnace casing

and when the KGAVG0101DFG Downflow Vent Guard Kit is used

external to the furnace.

6. Accessory Downflow Vent Guard Kit, KGAVG0101DFG required

in downflow installations with bottom vent configuration.

7. Chimney Adapter Kit required for exterior masonry chimney

applications. Refer to Chimney Adapter Kit, KGACA02014FC and

KGACA02015FC for sizing and complete application details.

8. Secure vent connector to furnace elbow with (2) corrosion-resistant

sheet metal screws, spaced approximately 180° apart.

9. Secure all other single wall vent connector joints with (3) corrosion

resistant screws spaced approximately 120° apart. Secure Type B vent

connectors per vent connector manufacturer’s recommendations.

26