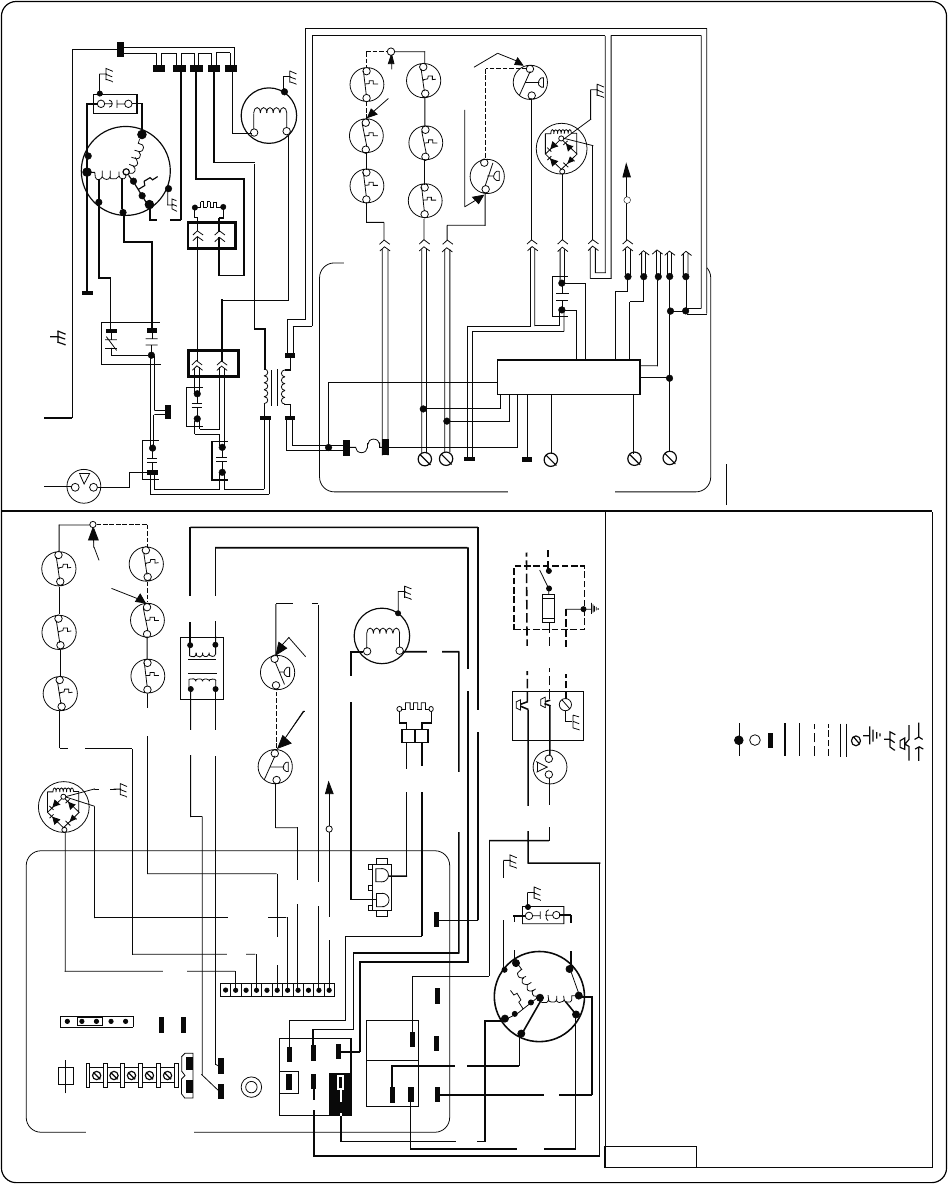

Fig. 39—Furnace Wiring Diagram

A02141

PCB

J 2

R

W

C

HUM

EAC-2

JB

L

E

G

E

N

D

LS 1, 2 LIMIT SWITCH, AUTO-RESET, SPST(N.C.)

OL AUTO-RESET INTERNAL MOTOR OVERLOAD

TEMPERATURE SWITCH (N.C.)

PCB PRINTED CIRCUIT BOARD CONTROL

PL1 11-CIRCUIT PCB CONNECTOR

PL2 2-CIRCUIT CONNECTOR

PL3 2-CIRCUIT HSI, CONNECTOR

PRS PRESSURE SWITCH, SPST-(N.O.)

TEST/TWIN COMPONENT TEST & TWIN TERMINAL

TRAN TRANSFORMER-115VAC/24VAC

JUNCTION

UNMARKED TERMINAL

PCB CONTROL TERMINAL

FACTORY WIRING (115VAC)

FACTORY WIRING (24VAC)

FIELD WIRING (115VAC)

FIELD WIRING (24VAC)

CONDUCTOR ON CONTROL PCB

FIELD WIRING SCREW TERMINAL

FIELD EARTH GROUND

EQUIPMENT GROUND

FIELD SPLICE

PLUG RECEPTACLE

L1

L1

BLWR

BHT/CLR

TO 115VAC FIELD DISCONNECT SWITCH

EQUIPMENT GROUND

SPARE-1

HEAT

COOL

START

OL

HI

MED LO

LO

BLWM

SCHEMATIC DIAGRAM

(NATURAL & PROPANE GASES)

1

HSI

2

PL3

CAP

L2

NOTES:

327559-101 REV. E

om

NEUTRAL

L2

ILK

FU2

L1

ILK

RED

BLU

ORN

GRN/YEL

TEST/TWIN

24V

FU1

LED

12345678910

BLOWER OFF-DELAY

JUMPER SELECT OR

YEL

OL

START

BLK

WHT

WHT (COM)

BLK BLK

WHT

WHT

2

1

PL2

BLWM

CAP

SPARE 1

EAC-1

PR1

L1

SEC-2

SEC-1

EAC-2

PL1

BRN

BRN

RED (LO)

WHT

(COM)

BLU

(MED LO)

COM

G

BLK (HI)

115VAC

PR1

TRAN

24VAC

LGPS

PRS

FSE

IDM

(WHEN USED)

F U 1

NOTE #6

R

W

SEC-1

SEC-2

HUM

CPU

G

C

GVR

OM

Y

1. If any of the original equipment wire is replaced use wire rated for 105°C.

2. Use only copper wire between the disconnect switch and the furnace junction box (JB).

3. This wire must be connected to furnace sheet metal for control to prove flame.

4. Symbols are electrical representation only.

5. Solid lines inside PCB are printed circuit board conductors and are not included in legend.

6. Replace only with a 3 amp fuse.

7. Inducer (IDM) and blower (BLWM) motors contain internal auto-reset thermal overload switches (OL).

8. Neutral connections are interchangeable within the NEUTRAL connector block.

9. Blower motor speed selections are for average conditions, see installation instructions for details on

optimum speed selection.

10. Factory connected when BVSS (Chimney Adapter Accessory Kit) is not installed.

11. Factory connected when LGPS is not used.

12. Ignition-lockout will occur after four consecutive unsuccessful trials-for-ignition. Control will

auto-reset after three hours.

13. Blower-on delay: gas heating 25 seconds, cooling or heat pump 2 seconds.

14. Blower-off delay: gas heating selections are 90, 120, 150 or 180 seconds, cooling or heat pump

90 seconds or 5 seconds when J2 is cut.

TRAN

FSE

LS1

RED

RED

BLU

RED

WHT

BLK

BLK

WHT

IDM

HSI

WHT

BLK

2

1

PL3

FRS1

11

EAC-1

HSIR

1

2

PL2

IDR

FUSE OR CIRCUIT BREAKER &

DISCONNECT SWITCH (WHEN REQ’D)

NOTE #2

GRN/YEL

GRN/YEL

GND

NOTE #3

NOTE #6

WHT

NOTE #5

GV

GRN/YEL

RED

24V

NOTE #11

PRS

(WHEN USED)

LGPS

YEL

L2

NEUTRAL

NOTE #11

GV

NEUTRAL

NOTE #8

BHT/CLR BLOWER MOTOR SPEED CHANGE RELAY, SPDT

BLWR BLOWER MOTOR RELAY, SPST-(N.O.)

BLWM BLOWER MOTOR, PERMANENT-SPLIT-CAPACITOR

BVSS BLOCKED VENT SHUTOFF SWITCH, MANUAL-RESET, SPST -(N.C.)

CAP CAPACITOR

CPU MICROPROCESSOR AND CIRCUITRY

DSS DRAFT SAFE GUARD SWITCH, AUTO-RESET, SPST -(N.C.)

EAC-1 ELECTRONIC AIR CLEANER CONNECTION (115 VAC 1.0 AMP MAX.)

EAC-2 ELECTRONIC AIR CLEANER CONNECTION (COMMON)

FRS 1, 2 FLAME ROLLOUT SW. -MANUAL RESET, SPST-(N.C.)

FSE FLAME-PROVING ELECTRODE

FU 1 FUSE, 3 AMP, AUTOMOTIVE BLADE TYPE, FACTORY INSTALLED

FU 2 FUSE OR CIRCUIT BREAKER CURRENT INTERRUPT DEVICE

(FIELD INSTALLED & SUPPLIED)

GND EQUIPMENT GROUND

GV GAS VALVE-REDUNDANT

GVR GAS VALVE RELAY, SPST-(N.O.)

HSI HOT SURFACE IGNITER (115 VAC)

HSIR HOT SURFACE IGNITER RELAY, SPST-(N.O.)

HUM 24VAC HUMIDIFIER CONNECTION (0.5 AMP. MAX.)

IDM INDUCED DRAFT MOTOR, SHADED-POLE

IDR INDUCED DRAFT MOTOR RELAY, SPST-(N.O.)

ILK BLOWER ACCESS PANEL INTERLOCK SWITCH, SPST-(N.O.)

J1 BLOWER - OFF DELAY JUMPER SELECTOR - HEATING

J2 BLOWER - OFF DELAY JUMPER - COOLING

JB JUNCTION BOX

LED LIGHT-EMITTING DIODE FOR STATUS CODES - RED

LGPS LOW GAS PRESSURE SWITCH, SPST-(N.O.)

NEUTRAL

BHT/CLR

CONNECTION DIAGRAM

COOL

HEAT

TEST/TWIN

PCB

NOTE #5

BLW

BLWR

DSS

FRS2

BVSS

(WHEN USED)

NOTE #10

FRS1

FRS2

DSS

BVSS

LS1

NOTE #10

(WHEN USED)

L 2

PRINTED CIRCIUT BOARD

PRINTED CIRCIUT BOARD

PL1-1

PL1-6

PL1-2

PL1-4

PL1-3

PL1-10

PL1-5

PL1-9

PL1-11

PL1-7

PL1-8

SPARE 2

LS2

(WHEN USED)

LS2

(WHEN USED)

Y

RED

RED

RED

RED

ORG

ORG

J1

180

150

120

90

27