UTILITY STITCHES —————————————————————————————————————————————————

—

80

GETTING READYCONTENTS SEWING BASICS UTILITY STITCHES APPENDIX INDEX

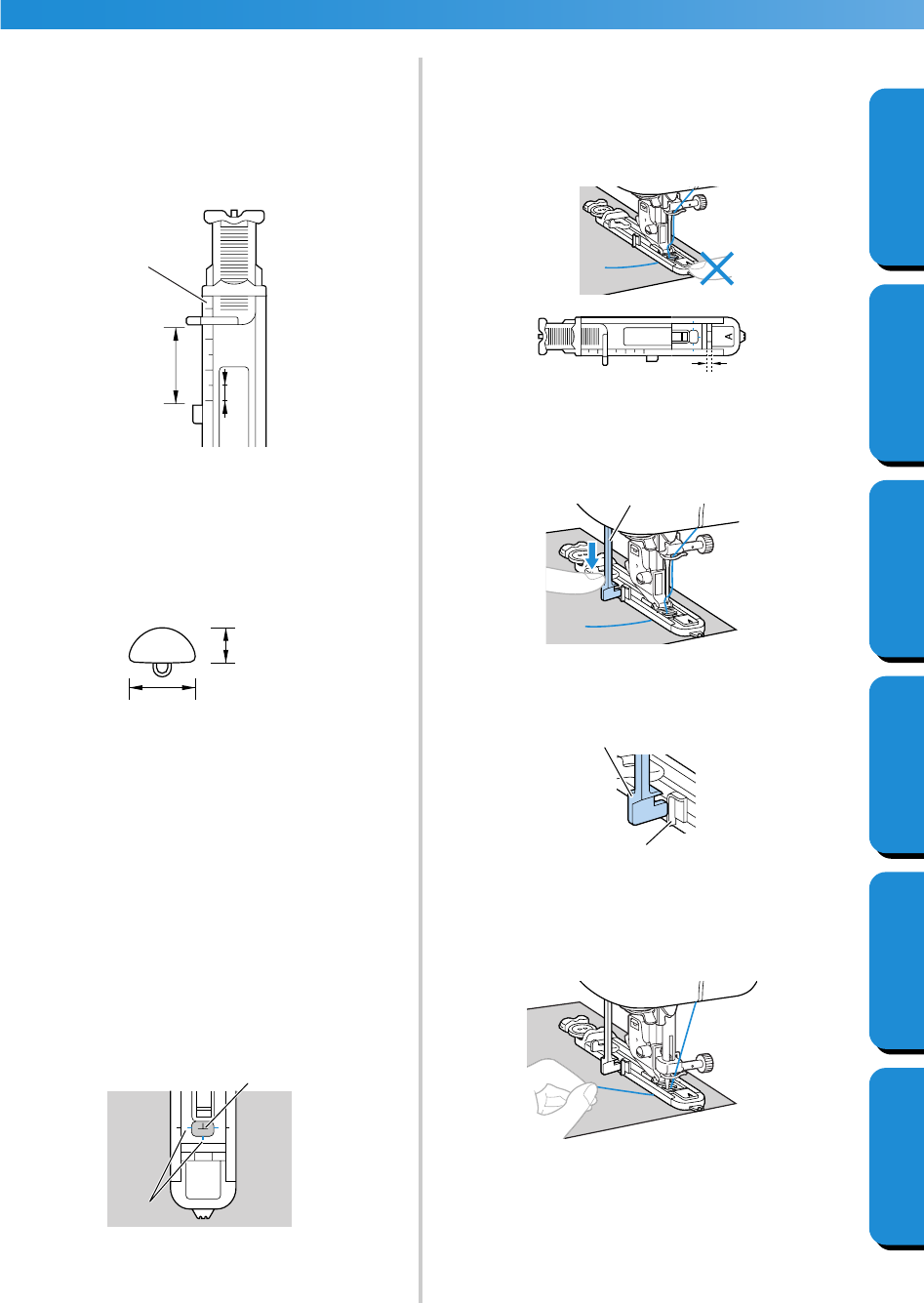

■ If the button does not fit in the button guide

plate

Add together the diameter and thickness of

the button, and then set the button guide

plate to the calculated length. (The distance

between the markings on the presser foot

scale is 5 mm (3/16 inch).)

1 Presser foot scale

2 Length of buttonhole

(Diameter + thickness of button)

3 5 mm (3/16 inch)

Example: For a button with a diameter of 15 mm

(9/16 inch) and a thickness of 10 mm (3/8 inch),

the button guide plate should be set to 25 mm

(1 inch) on the scale.

1 10 mm (3/8 inch)

2 15 mm (9/16 inch)

X The size of the buttonhole is set.

3

Attach buttonhole foot “A”.

• For details, refer to “Replacing the presser

foot” (page 37).

4

Select a stitch.

• For details, refer to “Selecting stitching”

(page 68).

5

Position the fabric with the front end of the

buttonhole mark aligned with the red marks

on the sides of the buttonhole foot, and then

lower the presser foot lever.

1 Mark on fabric

2 Red marks on buttonhole foot

Pass the upper thread down through the hole

in the presser foot.

• When lowering the presser foot, do not push

in the front of the presser foot, otherwise the

buttonhole will not be sewn with the correct

size.

1 Do not reduce the gap.

6

Pull down the buttonhole lever as far as

possible.

1 Buttonhole lever

The buttonhole lever is positioned behind the

bracket on the buttonhole foot.

1 Buttonhole lever

2 Bracket

7

Gently hold the end of the upper thread in

your left hand, and then start sewing.

X Once sewing is completed, the machine

automatically sews reinforcement stitches,

then stops

8

Cut the threads, raise the presser foot lever,

and then remove the fabric.

1

3

2

1

2

A

1

2

1

1

1

2