4. ASSEMBLY

4-16. Work clamp arm mechanism (KE-432B, 432C)

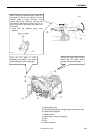

Align with the screw stop and push down

from above while tightening the set screw.

KE-430B, 430C series

90

After installing, carry out test feeding and check that the needle hole is inside the work clamp and the

feed plate frame. If the needle hole is not inside the frame, adjust the position of the button clamp holder

support and feed plate.

3428Q

3426Q

Be careful not to drop these two ball

bearings when installing the feed bracket

assembly.

Place the tack length feed slide

block into the groove of the feed

bracket assembly, and then use

the screws to install it together

with the feed bracket guide plate.

Tack length feed

slide block

Refer to “4-20. Work clamp arm

mechanism (Applying grease)”

First place onto A, then insert into B

an

d place onto C.

1. Fee

d bracket assy

2. Feed bracket guide plate

3. Screws [8 pcs]

4. Rod end

5. Tack width feed shaft

6. Set screw

7. Rubber cap

8. Feed plate

9. Screws [2 pcs]

10. Work clamp felt

11. Button clamp holder

support

12. Plain washers [2 pcs]

13. Bolts [2 pcs]

14. Work clamp arm assy

15. Button clamp holder shaft

16. Set screws [2 pcs]

17. Nuts [2 pcs]

Adjusting screw

Co

mpression spring

18. Work clamp carrier rod assy

Carry out the adjustment in “5-24. Adjusting the home

position” before installing the feed plate.

19. Washer

20. Bolt