4. ASSEMBLY

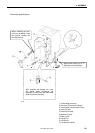

4-5. Work clamp lifter mechanism (Solenoid specifications)

When assembling, apply grease to the required places while referring to “4-5-1. Applying grease”.

KE-430B, 431B, 433B, 434B

KE-430C, 4

31C, 434C

Secure link shaft, A using the set

scre

w so that link, B (8) is centered

in the bush.

<KE-433B, 434B, 434C>

3351Q

1.

Work clamp lifter link-related parts [Insert from above the arm]

2. Link shaft, B [Place into the forked section of the thread wiper driving lever (2)]

3. Link shaft, A [Pass through the washer and link A (3)]

4.

Snap pins [2 pcs: Attach to both ends of link shaft A]

5. Set screws [2 pcs]

6

. Work clamp lifter stopper rubber

7. Work clamp plate [Insert from below the arm]

8. Link shaft, C [Pass through link B (8) and the work clamp plate]

9. Snap pins [2 pcs: Attach to both ends of link shaft C]

10. Presser solenoid assy [Insert from above the arm]

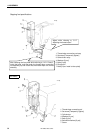

KE-430B, 430C series

65