11

Express® Lavatory System - MG Series with Battery Infrared Control

Installation Instructions MG-2/BIR3

Bradley Corporation • 215-1510 Rev. D; ECN 07-815 8/23/07

Installation Instructions continued . . .

Step 7: Connecting electrical and supply tubing

WARNING: The MG-2/BIR3 must be connected to the 6 VDC battery. Connection to 110

VAC may cause personal injury and/or damage to electronics. Connection of leads

other than shown may cause permanent sensor damage.

CAUTION: To avoid activating the sprayhead valve, make sure to connect the sensor

cable plugs to the circuit board before inserting the batteries into the battery holder.

If the cable is connected or disconnected while the batteries are installed, the station

will activate and continue running for 75 seconds.

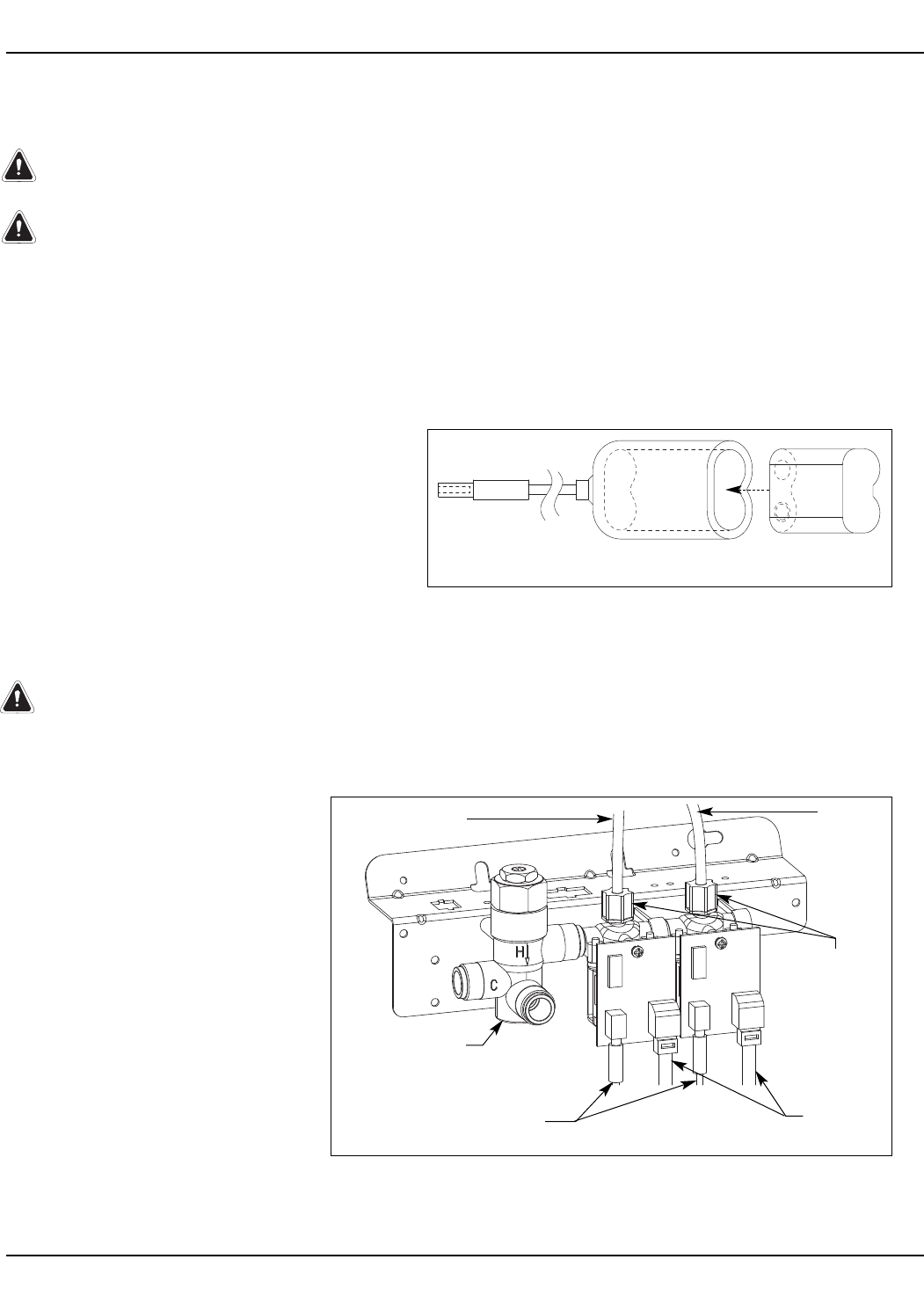

1. Snap the sensor plugs from the sprayhead into the proper valve’s circuit board.

2. Insert the batteries into the battery holders (see Figure 7a). Mount the battery holders (with

batteries) in a convenient location on the frame using the hook-and-loop fastener provided.

3. Snap the battery holder plugs into the female circuit board plugs.

4. Insert the two sprayhead supply tubes

into the two solenoid tube connectors by

loosening the compression nut and

firmly pushing the tubing into the tube

connector until the tubes are fully

seated, then re-tighten the compression

nut by hand (see Figure 7b).

5. Align the valve bracket mounting screws

with slots on the frame. Let the valve bracket slide down to lock into place.

6. Turn on the water supply to the MG-2/BIR3 and check for leaks. Pass your hand in front of each

station’s sensor until all the air is purged from the lines and water is flowing smoothly.

IMPORTANT: The Vernatherm™ valve is NOT factory-preset. Upon installation, the valve

temperature must be checked and adjusted to ensure delivery of safe water

temperature. Water in excess of 110°F (43°C) may cause scalding.

7. Check the temperature when approximately1.0 GPM water flow is reached and adjust if

necessary (the range of the

valve is 95°F–115°F

(35°C–43°C). To adjust the

temperature, first loosen the

temperature locking nut with

a wrench. Then using a blade

screwdriver, turn the

adjustment stem

counterclockwise to increase

the temperature or clockwise

to decrease the temperature.

Once desired temperature is

reached, tighten the nut to

prevent temperature change.

8. After testing is complete,

reinstall access panel to

frame. Fasten access panel

with the five panel screws and washers provided (see Figure 3 on page 8).

Figure 7b

RED

SUPPLY

TUBE

GREEN SUPPLY

TUBE

BATTERY

CABLE

SENSOR

CABLE

Figure 7a

BATTERY HOLDER (S83-177)

6-volt LITHIUM BATTERY

(261-010)

COMPRESSION

NUT (110-231)

VERNATHERM™

THERMOSTATIC

MIXING VALVE