10

Mount the burner to the appliance. The burner specifi ed

for packaged equipment will have a fl ange welded for the

required insertion. Follow the appliance manufacturer’s

instructions for mounting.

In the absence of instructions, or for retrofi ts, make sure

that the air tube insertion dimension, measured along

the side of the air tube from the welded fl ange to the end

of burner air tube, is correct.

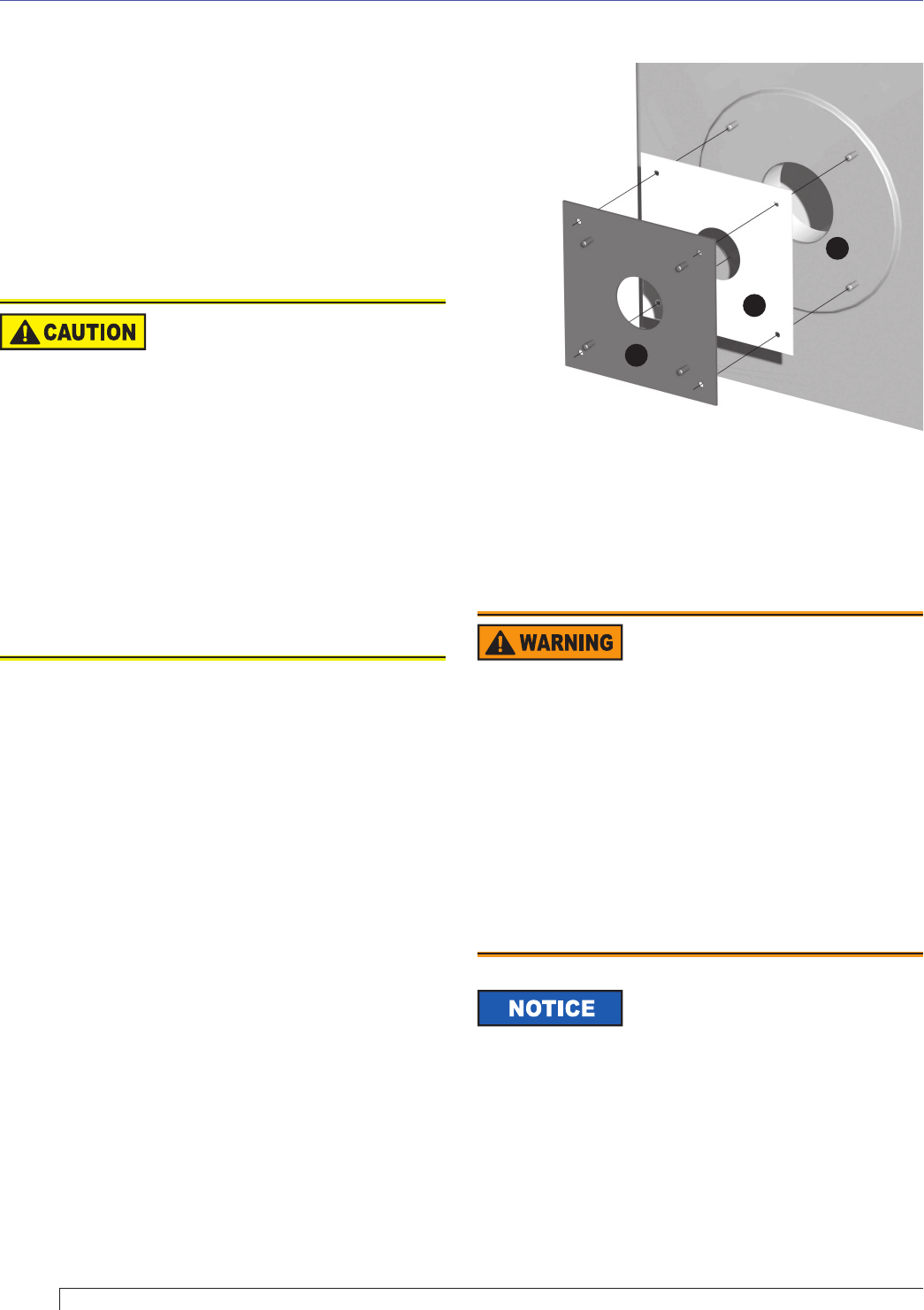

Figure 6 - Custom Mounting Plate

If this dimension cannot be achieved, protect the

end of the air tube by installing a suitable ceramic

refractory material such as a refractory mill board

capable of withstanding at least 2300 degrees F.

The entry hole diameter in the appliance should

be 1” larger than the air tube to facilitate ease of

installation and provide adequate protection.

Referring to Figure 6, if the front plate opening (C)

in the boiler is larger than the burner fl ange bolt

circle, then a custom mounting plate (A) of at least

1/4” thickness must be used with a suitable high-

temperature refractory material anchored on the fi re-

side. A suitable high-temperature gasket (B) must be

used for an effective seal.

Attach the plate and gasket to the boiler and tighten

the mounting nuts or bolts securely.

Verify that the air tube is ¼” back from fl ush (see

Figure 2), and there is nothing blocking the fl ame

zone that could cause fl ame impingement.

○

○

○

○

Mount the Burner

Protect the Air Tube from

Overheating

Overheating could cause damage to the air tube and

other combustion components leading to equipment

malfunction and impaired combustion performance.

The end of the air tube must not extend into the

combustion chamber unprotected unless it has

been factory-tested and specifi ed by the appliance

manufacturer.

The end of the air tube should be set back ¼”

from fl ush with the refractory inside wall to prevent

damage from overheating.

Refer to the instructions outlined in this section for

methods of additional protection.

y

y

y

A

B

C

Key:

A = Burner mounting fl ange

B = Gasket

C = Appliance mounting plate

Connect Gas Piping

Do Not Use Tefl on Tape on

Gas Piping

Damage to gas valve cutoff seals and valve bodies could

cause gas leaks and result in asphyxiation, explosion or

fi re.

Pieces of tape can be cut loose during installation

and lodge in gas valves causing cutoff seal

problems.

Tefl on tape ‘lubricates’ pipe threads, allowing iron

pipes to penetrate too deeply into aluminum valve

bodies causing distortion and leakage.

Use only pipe sealant compounds that are resistant

to the gas being used.

y

y

y

All gas piping installation must

comply with the latest edition of the

National Fuel Gas Code ANSI Z223.1 (NFPA 54) and

other applicable local codes.

The gas supply system must be sized to deliver at

least the minimum required pressure to the gas train

inlet. Contact your local gas utility for verifi cation of

gas pressures, allowable pressure drops, and any local

piping code requirements. Refer to Figure 7 for an

illustration of a gas piping layout and refer to Table 2 for

pipe sizing.

Section: Mount the Burner & Connect Gas Piping