Instruction Manual – Model AFG Oil Burner

7

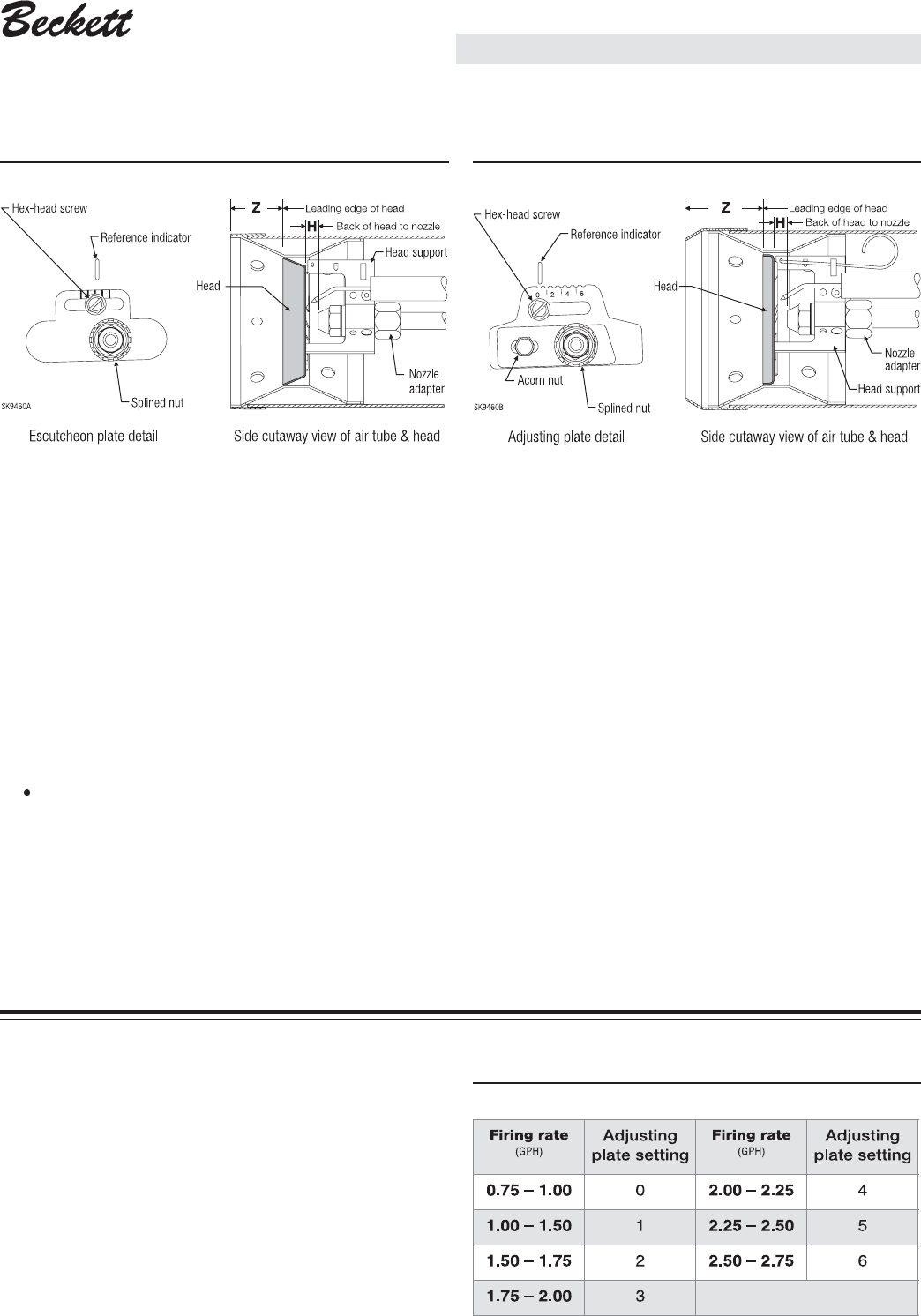

Figure 4 —“V1” heads (see Table 3 and Figure 2 for dimensions)

Prepare burner & site

Figure 3 —“L1” heads (see Table 3 and Figure 2 for dimensions)

Check/adjust "Z" dimension - "L1" head Check/adjust "Z" dimension - "V1" head

1. See Figure 3. The important "Z" dimension is the distance from the leading

edge of the head to the end of the air tube. This distance for L1 heads is

1 ³⁄₈" if the tube has a straight shroud (1 ³⁄₄" if the air tube has a conic

shroud). The "Z" dimension is factory set for burners shipped with the air

tube installed. Even if factory set, verify that the "Z" dimension has not been

changed.

2. Use the following procedure to adjust the "Z" dimension, if it is not correct:

• Turn off power to the burner.

• Disconnect the oil connector tube from the nozzle line.

• See Figure 3. Loosen the splined nut from the nozzle line. Loosen the

hex head screw securing the escutcheon plate to the burner housing.

• Place the end of a ruler at the leading edge of the head and, using a

straight edge across the end of the tube, measure the distance to the

end of the air tube. (A Beckett T500 gauge may also be used.)

Slide the nozzle line forward or back until this dimension is 1 ³⁄₈" for L1

heads if the air tube has a straight shroud (1 ³⁄₄" if the air tube has a

conic shroud).

• Tighten the hex head screw to secure the escutcheon plate to the burner

chassis. Then tighten the splined nut and attach the oil connector tube.

3. Recheck the "Z" dimension periodically when servicing to ensure the es-

cutcheon plate has not been moved. You will need to reset the "Z" dimen-

sion if you replace the air tube or nozzle line assembly.

1. See Figure 4. The important "Z" dimension is the distance from the leading

edge of the head to the end of the air tube. This distance for V1 heads is

1 ³⁄₄". The "Z" dimension is factory set for burners shipped with the air tube

installed. Even if factory set, verify that the "Z" dimension has not been

changed.

2. Use the following procedure to adjust the "Z" dimension, if it is not correct:

• Turn off power to the burner.

• Disconnect the oil connector tube from the nozzle line.

• See Figure 4. Loosen the splined nut from the nozzle line. Loosen the

hex head screw securing the escutcheon plate to the burner housing.

• Loosen the acorn nut. Move the head adjusting plate until the "0" lines

up with the reference indicator on the housing, and retighten the hex

head screw. Place the end of a ruler at the leading edge of the head and,

using a straight edge across the end of the tube, measure the distance

to the end of the air tube. Or use a Beckett T500 gauge. Slide the nozzle

line forward or back until this dimension is 1 ³⁄₄" for V1 heads. Tighten

the acorn nut.

• Tighten the hex head screw to secure the escutcheon plate to the burner

chassis. Then tighten the splined nut and attach the oil connector tube.

3. Recheck the "Z" dimension periodically when servicing to ensure the es-

cutcheon plate has not been moved. You will need to reset the "Z" dimen-

sion if you replace the air tube or nozzle line assembly.

1. After setting “Z” dimension, loosen head adjusting plate hex head screw and

nozzle line splined nut. Move the nozzle line assembly until the burner reference

indicator lines up with the head adjusting plate setting number given in

Table 3.

2. Tighten the hex head screw and splined nut. (DO NOT loosen the acorn nut

when setting head position.) Refer to the Beckett

OEM Specification Guide

or manufacturer's instructions for OEM settings.

3. The position of the head affects air flow volume and pattern. For most

applications, the burner will perform satisfactorily with the air adjustment

plate setting of Table 3.

4. If combustion results indicate the need for change, adjust the head position

adjusting plate forward or back one position at a time to optimize combustion.

Set head position adjusting plate (“V1” head only)

Table 3 — Starting adjusting plate settings with “V1” head