Instruction Manual – Model AFG Oil Burner

5

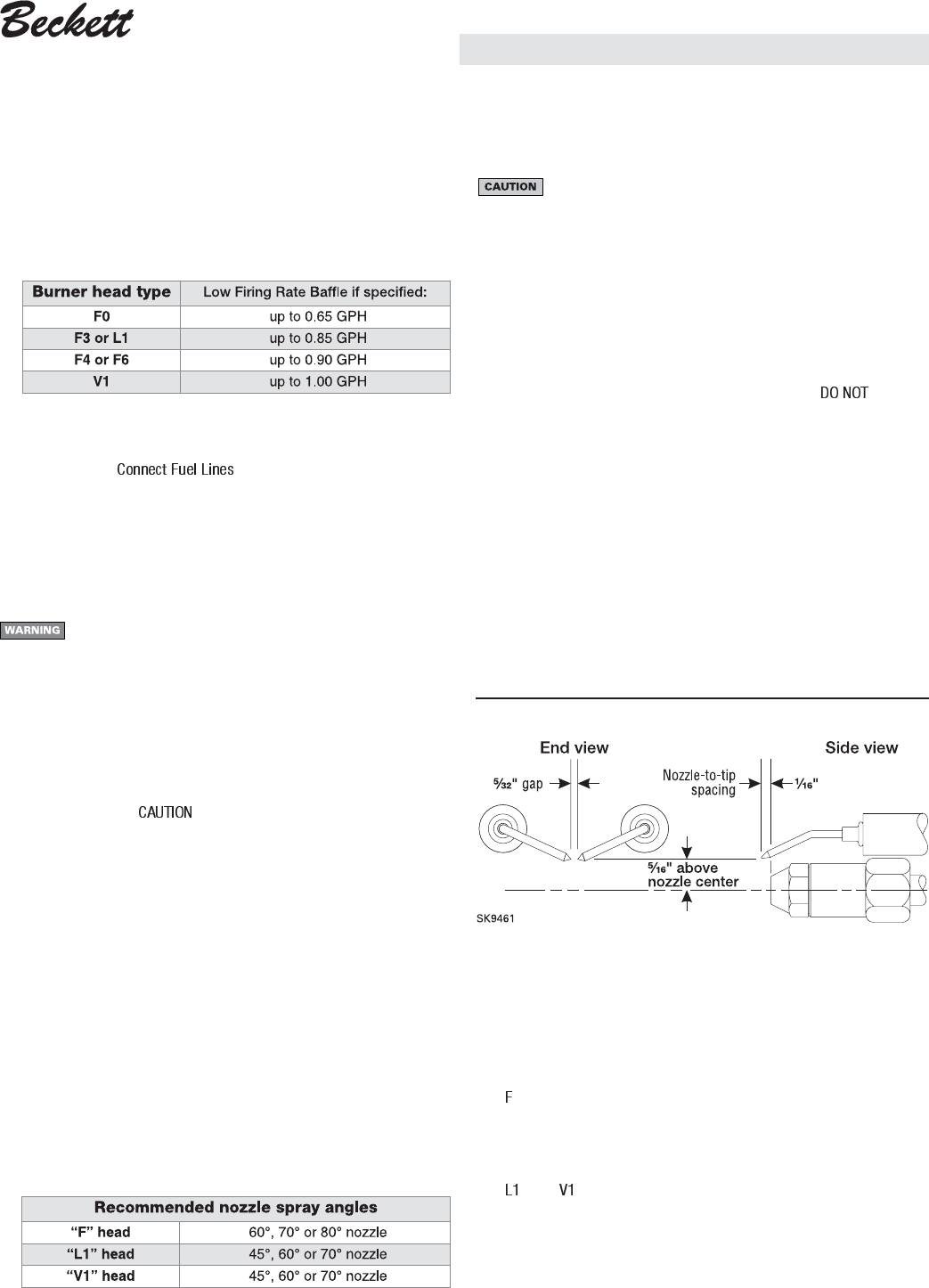

Figure 1 — Electrode settings

Install burner nozzle (if not already installed) (continued)

Use care when removing and installing oil nozzles:

• Inspect the nozzle adapter before installing nozzle. If it is grooved

or scratched on the sealing surface, replace the nozzle line assembly.

Otherwise, oil could leak at the nozzle-adapter joint, causing serious

combustion problems.

• Protect the nozzle orifice and strainer when installing. If the orifice

gets dirt in it or is scratched, the nozzle will not function properly.

• Do not over-torque the nozzle when installing. This will cause deep

grooves in the nozzle adapter, preventing a seal when a new nozzle

is installed.

• Use a wrench or vise to hold the nozzle adapter. attempt to

remove or replace nozzle without holding adapter. The nozzle

alignment could be seriously damaged. Use a nozzle wrench that

secures the adapter or use 3/4" and 5/8" open-end wrenches.

• Do not squeeze the electrodes too tightly when handling the nozzle

line assembly. This could change the electrode tip settings or

damage the ceramic electrode insulators.

• Carefully check and realign electrode tips after replacing nozzle,

ensuring the electrode settings comply with Figure 1.

Check/adjust electrodes

Check the electrode tip settings. Adjust if necessary to comply with the dimen-

sions shown in Figure 1. To adjust, loosen the electrode clamp screw and slide/

rotate electrodes as necessary. Securely tighten the clamp screw when finished.

Servicing nozzle line assembly

1. Turn off power to burner before proceeding.

2. Disconnect oil connector tube from nozzle line.

3. Loosen the two screws securing igniter retaining clips and rotate both clips

to release igniter baseplate. Then tilt igniter back on its hinge.

4. Remove splined nut.

5. “ ” head air tubes

Remove nozzle line assembly from burner, being careful not to damage the

electrodes or insulators while handling. To ease removal of long assemblies

(over 9 inches), rotate assembly 180° from installed position after pulling

partially out of tube.

6. “ ” and “ ” head air tubes

Slide nozzle line assembly forward (further into air tube) so the head clears

the venturi opening. Then rotate the nozzle line assembly 90° so the nozzle

line end points up. Pull the nozzle line assembly toward you and remove

assembly from burner.

7. To replace the nozzle assembly, reverse the above steps.

Low firing rate baffle

• The AFG Low Firing Rate Baffle (LFRB), item 7, page 11, reduces the air flow

(cfm). The LFRB is sometimes used for firing rates under 1.00 GPH as listed in

the table below. Refer to the appliance manufacturer’s instructions or the

Beckett

OEM Specification Guide

part number 6711. Do not omit the LFRB

when specified. Omitting the baffle when specified or installing the baffle

when not specified could result in poor burner performance.

Burner fuel unit

• Verify that the burner fuel unit is compatible with the oil supply system. For more

details, refer to “ ” on page 8.

Attach air tube (if not already installed)

If using a flange and gasket, slide them onto the air tube. Then attach the air tube

to the burner chassis using the four sheet metal screws provided. See Figure 2

on page 6 for details.

Install burner nozzle (if not already installed)

Make certain the nozzle is selected for the fuel unit pressure used.

For applications with fuel unit pressure above 100 psig, the nozzle rated capac-

ity will be less than the appliance firing rate. Use only the specified spray pat-

tern unless combustion test results indicate the need for a change. Failure to

use the correct nozzle size and type can result in unacceptable combustion,

possibly causing severe personal injury, death or substantial property damage.

1. Remove the plastic plug protecting the nozzle adapter threads.

2. Place a ³⁄₄" open-end wrench on the nozzle adapter. Insert the nozzle

into the adapter and finger tighten. Finish tightening with a ⁵⁄₈" open-

end wrench. Use care to avoid bending the burner head support legs or

electrodes. See , above right.

3. If you remove the head to replace the nozzle (type “L1” or “V1” heads),

carefully reconnect the head to the nozzle adapter, making sure to butt the

head support to the nozzle adapter shoulder (see Figures 3 and 4, page 7).

If the nozzle is already installed, remove the nozzle line assembly to verify that

the nozzle size and spray pattern are correct for the application (per appliance

manufacturer’s information or Beckett

OEM Specification Guide,

part number

6711. Verify that the electrode tip settings comply with Figure 1.

If the nozzle is not installed, obtain a nozzle of the manufacturer, capacity and

spray angle specified in appliance manufacturer’s information or Beckett

OEM

Specification Guide

, part number 6711. For conversions or upgrades, when in-

formation is not available for the application:

1. Refer to table below to select the mid-range nozzle spray angle for the head type

being used.

2. Fire the burner and make sure the combustion is acceptable and the flame is

not impinging on chamber surfaces.

3. If a shorter flame is needed, select a wider spray angle. If a longer flame is

needed, select a narrower spray angle.

4. Either hollow or solid spray patterns may be used. If combustion results are

not satisfactory with the selected spray pattern, try the other pattern.

Prepare burner & site

Prepare burner Prepare burner (continued)