Manual 2100-538E

Page 17 of 23

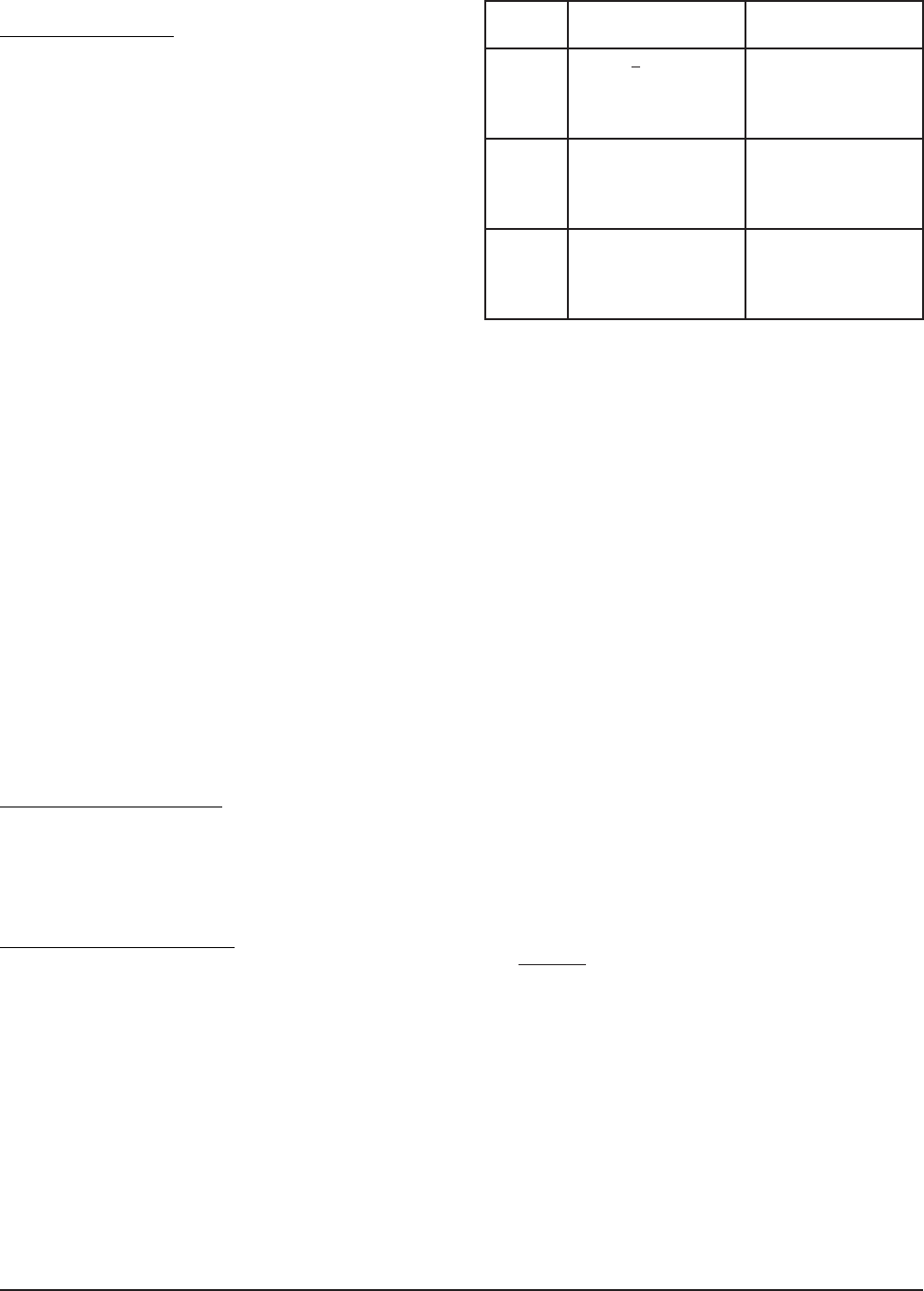

lortnoC

eciveDlamroNlamronbA

roodnI

rotoM

rewolB

lortnoC

draoB

DELdeRtil DELneerG,

trohsdnagnolsehsalf

dellacsinaFnehwsehsalf

otlangiSmorfcdV01-2,rof

.PnosirepmuJ.nommoC

neerGondna,DELdeRoN

sicdV01-2nehwsehsalf

otlangiSmorftneserp

.PnosirepmuJ.nommoC

roodtuO

rotoM

naF

lortnoC

draoB

gnolneerG.tiltonDELdeR

-2nehwsehsalftrohsdna

langiSmorftneserpcdV01

.draobnonommoCot

.PnosirepmuJ

neerGondna,tilDELdeR

sicdV01-2nehwsehsalf

otlangiSmorftneserp

.PnosirepmuJ.nommoC

cdV5

rewoP

ylppuS

caV42nehwtilDELdeR

tatneserpcdV5.tneserp

kcalBdilosdnadeRdilos

.flaHnosrepmujhtoB.seriw

.esufV052A3

toncdV5.tiltonDELdeR

dnadeRdilostatneserp

.seriwkcalBdilos

.flaHnosrepmujhtoB

.esufA3kcehC

COOLING SEQUENCE

Compressor Operation

The cooling capacity of the WV series is controlled by

loading or unloading the compressor. On a call for

cooling, the unloader solenoid is energized for one

second to ensure pressure equalization in the

compressor. The compressor contactor, RLY 2, is then

energized and the compressor will start. A PI control

loop then calculates the compressor capacity needed to

reach set point and modulates the compressor .

Modulation range is from 20% to 100% capacity.

Modulation is accomplished by a pulse width modulated

signal from OUT 8 which energizes the solid state relay

(SSR) and energizes or de-energizes the unloader

solenoid. The required compressor capacity is

calculated every 15 seconds.

20% load means 0 VDC for 3.0 seconds and 5 VDC for

12.0 seconds from OUT 8.

30% load means 0 VDC for 4.5 seconds and 5 VDC for

10.5 seconds from OUT 8.

40% load means 0 VDC for 6.0 seconds and 5 VDC for

9.0 seconds from OUT 8.

50% load means 0 VDC for 7.5 seconds and 5 VDC for

7.5 seconds from OUT 8.

60% load means 0 VDC for 9.0 seconds and 5 VDC for

6.0 seconds from OUT 8.

70% load means 0 VDC for 10.5 seconds and 5 VDC

for 4.5 seconds from OUT 8.

80% load means 0 VDC for 12.0 seconds and 5 VDC

for 3.0 seconds from OUT 8.

90% load means 0 VDC for 13.5 seconds and 5 VDC

for 1.5 seconds from OUT 8.

100% load means 0 VDC for 15 seconds and 5 VDC for

0.0 seconds from OUT 8.

Outdoor Temperature Sensor

A sensor probe projects out the bottom of the ECU

control box into the outdoor section, and this provides

input for the outdoor fan sequences below 55F and

above 115F described under Outdoor Fan Motor

Operation.

Discharge Temperature Sensor

This sensor is mounted on the compressor discharge line

and protects the compressor against overheating. It

opens at 250F and closes at 200F.

HEATING SEQUENCE

On a call for heating, if the space temperature falls 1°F

below setpoint, the first stage of heating, RLY 4, will

cycle ON. If the space temperature falls 3°F below

setpoint, the second stage of heating, RLY 5, will cycle

ON. Indoor Blower airflow is maintained at the Rated

unit airflow at all times during heating.

LEAD/LAG SEQUENCE

The digital controllers can be used for dual units used in

a redundant application by using the scheduling function

as follows:

1. The controllers should be mounted side by side so

that they are in the same temperature zone.

2. The time setting on both controllers need to be

synchronized to the same time of day. NOTE: there

is a 72-hour time retention if power is removed. If

power off-time exceeds 72 hours, the time clock in

each device must be reset to match. The exact time

is not important as long as both controllers are set

the same unless it is critical to control the time of

day when the units swap operating positions.

3. Set one controller #1 to be Occupied for a 12-hour

period and Unoccupied for the other 12-hour period.

Set controller #2 so that it is exactly the opposite.

Unoccupied for the 12-hour period when #1 is

Occupied and Occupied when #1 is Unoccupied.

4. Set Occupied cooling setpoint the same for each

controller, and Unoccupied the same for each. 4°F

difference is suggested.

5. Set controllers to “Auto” mode of operation.

Example:

1. Both Unit #1 and #2 have Occupied setpoint of

74°F and Unoccupied setpoint of 78°F

2.

Unit #1 set for Occupied from 1:00 a.m. to 1:00

p.m. & Unoccupied from 1:00 p.m. to 1:00 a.m.

3.

Unit #2 set for Unoccupied from 1:00 a.m. to

1:00 p.m. & Occupied from 1:00 p.m. to 1:00 a.m.

4. Every 12 hours the units will swap position as

being the lead unit, and the lag unit is available

for back up operation at the higher temperature

should the situation ever arise.