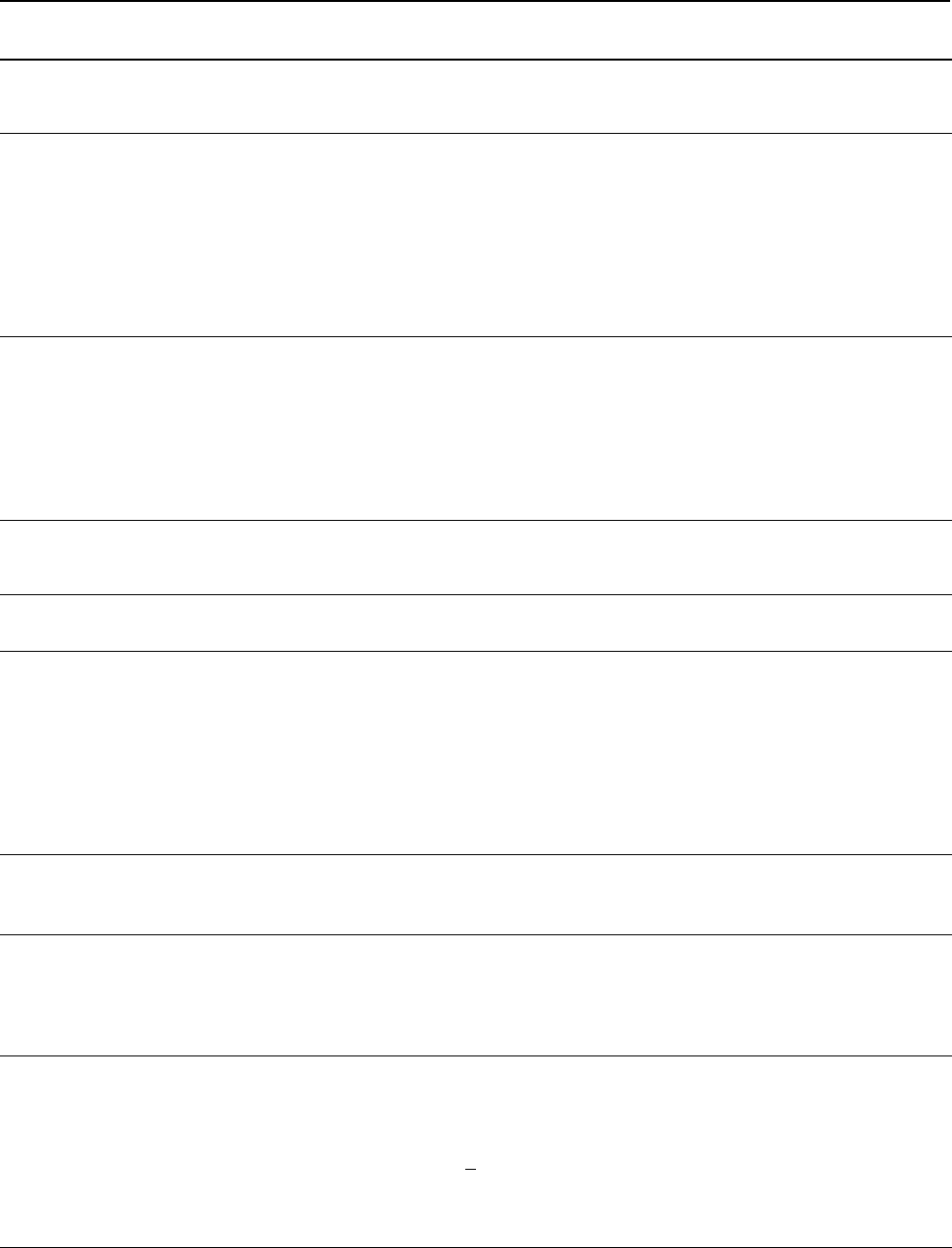

InRow RD 10 kW Air Cooled Operation and Maintenance44

Troubleshooting

Problem Possible Cause Corrective Action

Controls erratic or

inoperative

• Inlet temperature to cooling

unit is higher than rated

maximum temperature

• Reduce the load or add additional cooling equipment.

Fans fail to start

• Power supplies are not

operating properly

• Confirm that the power supplies are seated properly and fully

engaged. This is indicated by a green LED.

• Confirm that the cooling unit is plugged in and is receiving

power.

• Failed power supply • Replace the power supply if the LED is red.

• Cooling unit shutd own due to

an external command

• Temporarily remove the user contact cable, if it is connected.

• Single fan fails to start • Verify that the fan circuit breaker is

ON.

Cooling unit cannot

obtain setpoint

• Improper placement of remote

temperature sensor

• Verify that the remote temperature sensor is properly located

in the cold aisle.

• Dirty filter • Clean the filter.

• Dirty coil • Clean the coil.

• Application error • For assistance, contact APC at a number on the back cover of

this manual.

• Heat load is too far away • Place the cooling unit closer to the heat load.

Water carryover

• Improper fan speed selected • RACS and HACS modes only. Select the next highest fan

speed setting. For example, change the fan speed setting from

Low to Med/Low.

Temperature control

not tight enough

• Improper placement of remote

temperature sensor

• Verify that the remote temperature sensor is properly located

in the cold aisle.

Water on outside of

cooling unit

• Condensate drain hose is not

connected or not properly

routed outside the cooling unit

• Verify that the condensate drain hose is properly connected to

the pump and properly routed outside of the cooling unit.

• Verify that the condensate drain line does not exceed 4.9

meters (16 feet) lift and 15.4 meters (50.0 feet) horizontal run.

• Leak in piping system • Locate and repair the leak.

• Cooling unit not leveled

properly

• Adjust the leveling feet of the cooling unit.

• Damaged piping insulation • Identify damaged area and repair the insulation.

Display interface not

operational but

cooling unit operates

• Display interface not

connected properly

• Verify that the display interface cable is connected properly.

Incorrect air pressure

• False filter clogs • Verify that the ends of the clear plastic air tubes are not

obstructed.

• Verify that the clear plastic air tubes are connected to the

controller.

• Verify that the clear plastic air tubes are not pinched.

Alarms do not show

up on monitoring

equipment (Customer

Output Contact)

• External monitoring equipment

is not receiving power or is not

functioning properly

• Confirm that power, if required, is being supplied to the

external equipment.

• If the cooling unit (+12 V or +24 V) is providing power to the

external equipment, verify that the external equipment is

<

50 mA.

• Test the external equipment by bypassing the output contact.

• Verify Customer Output Contact settings. See “Contacts” on

page 17.